Mono-metallocene complex and application thereof, and ethylene polymerization method

A single metallocene and complex technology, applied in the field of olefin polymerization, can solve the problems of inability to catalyze the polymerization reaction, poor temperature resistance of the catalyst, inability to catalyze the copolymerization reaction of ethylene and α-olefin, etc. It is difficult to achieve molecular weight and avoid molecular weight reduction , to avoid the effect of thermal decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

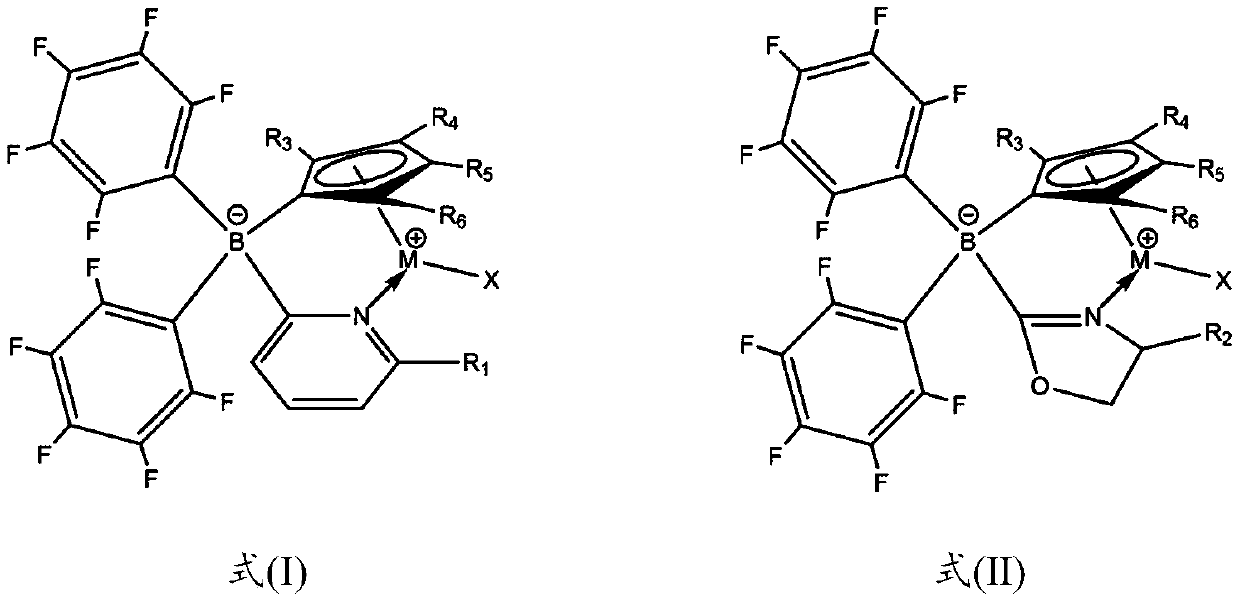

[0063] The synthesis of embodiment 1 complex

[0064]

[0065] Among them, the structure of the ligand H1L1-H1L5 is as follows:

[0066] H1L1:R 1 = H, R 3 =R 4 =R 5 =R 6 = Me;

[0067] H1L2:R 1 = Me,R 3 =R 4 =R 5 =R 6 = Me;

[0068] H1L3:R 1 =iPr, R 3 =R 4 =R 5 =R 6 = Me;

[0069] H1L4:R 1 = Me,R 3 , R 4 Linked to form phenyl, R 5 =R 6 =H, i.e. Mao ring=In;

[0070] H1L5:R 1 = Me,R 3 , R 4 Linked to form phenyl, R 5 , R 6 Linked to form a phenyl group, i.e. the cyclocene=Flu;

[0071] The synthesis process of ligands H1L1-H1L5 is as follows:

[0072]

[0073] Compound (A) bis(pentafluorophenyl) borate was synthesized with reference to Chem.Commun., 2018, 54, 7243-7246:

[0074] 3.62g of (C 6 f 5 ) 2 BOH (10mmol, purchased from Alfa Aesar company) was dissolved in 100mL of dry dichloromethane, and 10g of activated Molecular sieves, and 11 mmol of cyclopentanol was added thereto, the mixture was stirred at room temperature for 4 h, the mole...

Embodiment 2

[0146] Embodiment 2Ethylene homopolymerization

[0147] The polymerization reaction is carried out in a 250mL stainless steel autoclave. Heat the polymerization autoclave equipped with mechanical agitation to 120°C, vacuum the air for 1 hour, adjust the system to the temperature required for polymerization, fill in 0.1MPa ethylene gas, and pour into the polymerization autoclave. Add 60mL of dry and purified toluene solution containing co-catalyst to it, keep it warm for a period of time until the temperature is constant, feed 0.5MPa ethylene gas, then add the main catalyst, and stir for a period of time. After the end of the polymerization reaction, release the residual ethylene gas, open the reactor, pour the obtained polymerization reaction mixture into the mixed solution of 3M hydrochloric acid and ethanol with a volume ratio of 1:1, stir for 5 minutes, filter, and dry the polyethylene product in a vacuum oven , Weigh its quality, measure its molecular weight and melting po...

Embodiment 3

[0153] Embodiment 3 Ethylene and α-olefin (1-hexene and 1-octene) copolymerization

[0154]The polymerization reaction is carried out in a 250mL stainless steel autoclave. Heat the polymerization autoclave equipped with mechanical stirring to 120 ° C, vacuumize for 1 hour, fill in 0.1 MPa ethylene gas, adjust the system to the required temperature conditions for polymerization, and pour into the polymerization autoclave Add 60mL of toluene mixed solution containing a certain amount of alkylaluminum and a certain concentration of α-olefin (1-hexene or 1-octene), keep it warm for a period of time until the temperature is constant, feed 0.5MPa ethylene gas, and then add the main catalyst, Stir for a while. Let off residual ethylene gas after the end of the polymerization reaction, open the reaction kettle, pour the obtained polymerization reaction mixture into a mixed solution of 3M hydrochloric acid and ethanol with a volume ratio of 1:1, filter after stirring for 5 minutes, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com