Synthesis of copper complex and application of copper complex as photodegradation catalyst

A copper complex and hexahydrate technology is applied in the application field of degrading methylene blue dye, can solve the problems of low efficiency, secondary pollution, high energy consumption, and achieves the effects of simple process, easy separation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the synthesis of complex

[0023] 11.9mg of Cu(NO 3 ) 2 ·6H 2 O, 10.5mg of H 2 AIP, 16.5 mg of L were dissolved in 8 mL of water, ultrasonically oscillated for 5 min, transferred to the polytetrafluoroethylene liner of a 25 mL hydrothermal reaction kettle, reacted for 72 hours at a temperature of 150 ° C, and the resulting product was washed twice with water (2 mL / times), to obtain blue transparent bulk crystals.

Embodiment 2

[0024] Embodiment 2: Structural characterization of complexes

[0025] Use a microscope to select a single crystal of a suitable size, and use a Siemens (Bruker) SMART CCD diffractometer (graphite monochromator, Mo-Ka, ) to collect diffraction data. Diffraction data were corrected for absorption using the SADABS program. Data restoration and structure elucidation were done using the SAINT and SHELXTL programs, respectively. The coordinates of all non-hydrogen atoms were determined by the least squares method, and the positions of the hydrogen atoms were obtained by the theoretical hydrogenation method. The crystal structure was refined using the least squares method. Figure 1(a) and Figure 1(b) show that [Cu(L)(AIP)(H 2 O)·H 2 O] n Basic coordination and stacking methods. Some parameters of its crystallographic diffraction point data collection and structure refinement are shown in the table below.

[0026] Crystallographic data of the complexes in Table 1

[0027] ...

Embodiment 3

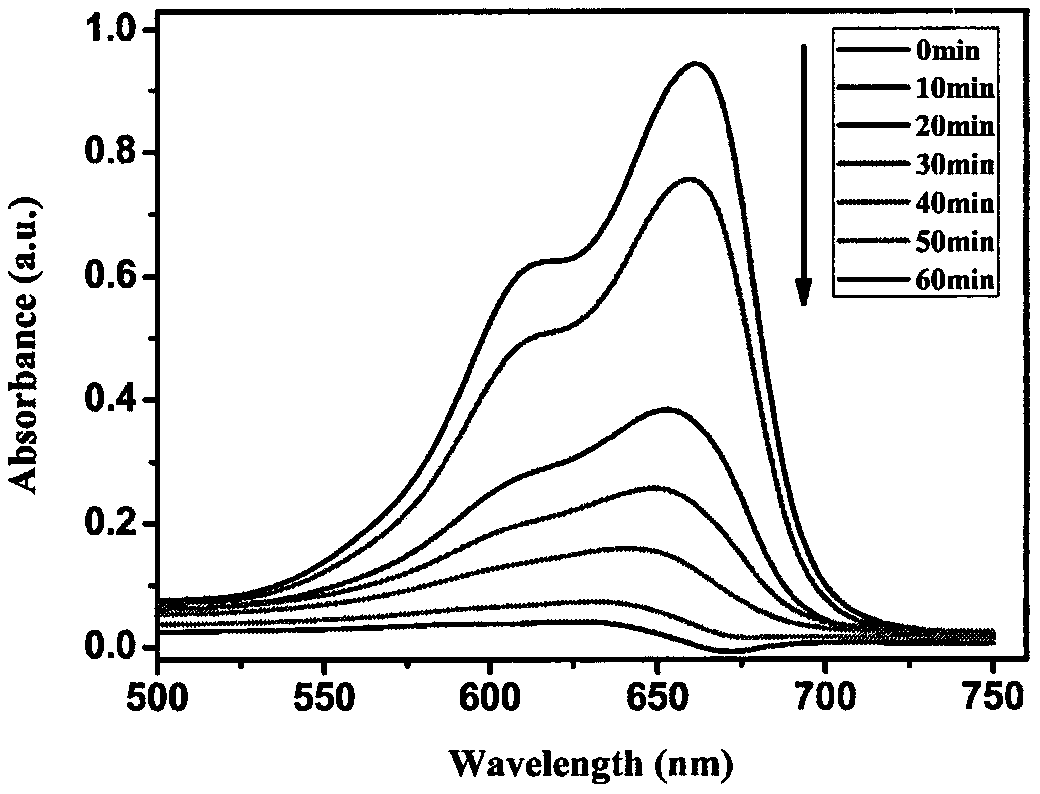

[0030] Embodiment 3: the photodegradation of complex

[0031] Weigh 30 mg of the copper complex synthesized by the present invention and add it to 50 mL of methylene blue aqueous solution (10 mg / L), then add 50 uL of H 2 o 2 , stirred in the dark for 30 minutes to make the surface of the complex reach adsorption-desorption equilibrium, then irradiated with visible light while stirring, took 1 mL of methylene blue aqueous solution every 10 minutes, and immediately tested the change of absorbance. The result of photodegradation shows that the degradation rate of the complex for methylene blue is as high as 91.5% respectively within 60min, and can be recycled for many times (such as figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com