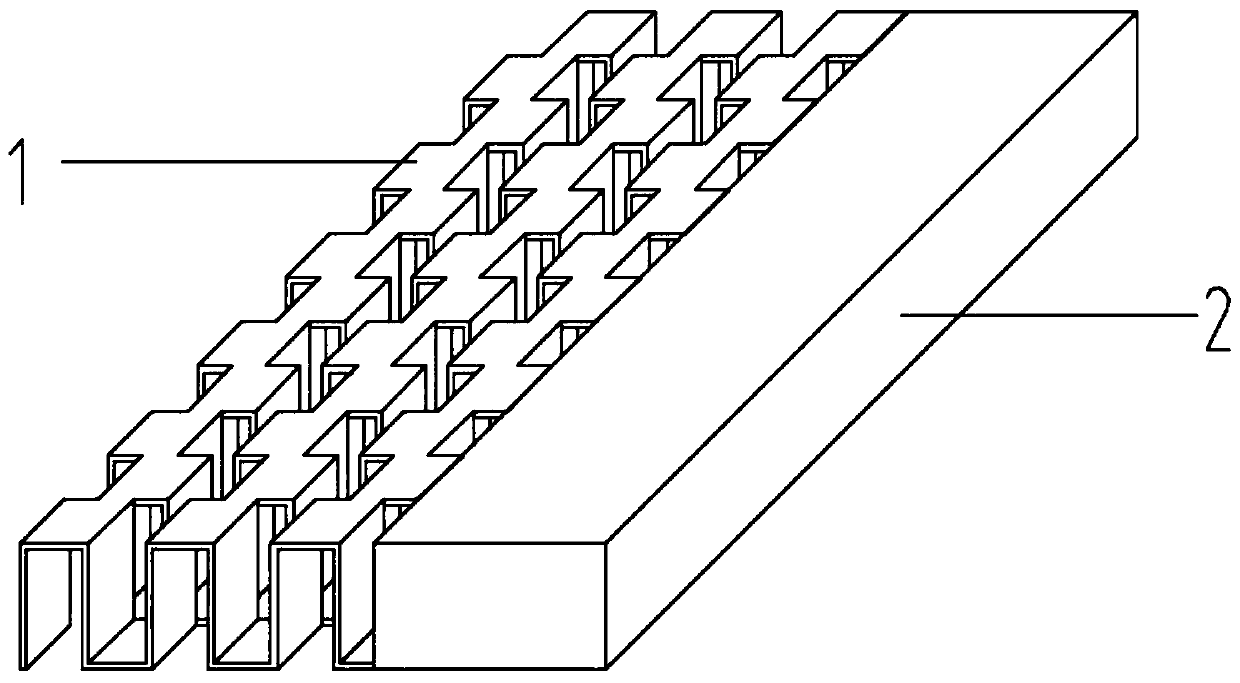

Process for effectively controlling core deformation of light titanium alloy plate-fin heat exchanger

A finned heat exchanger, titanium alloy plate technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., to achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a process for effectively controlling the core body deformation of a light titanium alloy plate-fin heat exchanger, which includes the following steps:

[0032] 1) fin forming;

[0033] 2) Core assembly: place the assembly core on the shaping fixture plate;

[0034] 3) Vacuum brazing: Put the workpiece into the furnace to evacuate, gradually raise the temperature of the furnace slowly, and keep it warm for 10 minutes. The solder is circulated at low temperature, and then the furnace temperature is slowly lowered to let the solder cool down;

[0035] The height of the fins is 0.04mm higher than the height of the seals, leaving a certain deformation space for the fins, so that it has enough support; the material of the fins is titanium alloy, and the thickness is 0.08mm; the temperature of the low-temperature flow of solder is 880°C.

[0036] Wherein, by weight, the solder includes the following components:

[0037] Ni 35.0; Cr 3.0; B 2.0; Mn 8.0;...

Embodiment 2

[0039] The invention provides a process for effectively controlling the core body deformation of a light titanium alloy plate-fin heat exchanger, which includes the following steps:

[0040] 1) fin forming;

[0041] 2) Core assembly: place the assembly core on the shaping fixture plate;

[0042] 3) Vacuum brazing: Put the workpiece into the furnace to evacuate, gradually raise the temperature of the furnace slowly, and keep it warm for 20 minutes. The solder is circulated at low temperature, and then the furnace temperature is slowly lowered to cool the solder;

[0043] The height of the fins is 0.06mm higher than the height of the seal; leave a certain deformation space for the fins so that it has enough support; the material of the fins is titanium alloy, and the thickness is 0.09mm; the temperature of the low-temperature flow of solder is 890°C.

[0044] In parts by weight, the solder includes the following components:

[0045] Ni 39.0; Cr 5.0; B 3.0; Mn 6.0; Si 8.0; Cu 4...

Embodiment 3

[0047] The invention provides a process for effectively controlling the core body deformation of a light titanium alloy plate-fin heat exchanger, which includes the following steps:

[0048] 1) fin forming;

[0049] 2) Core assembly: place the assembly core on the shaping fixture plate;

[0050] 3) Vacuum brazing: put the workpiece into the furnace to evacuate, gradually raise the temperature of the furnace slowly, and keep it warm for 30 minutes. The solder is circulated at low temperature. The temperature of the solder is 895°C, and then slowly lower the furnace temperature to let the solder cool ;The height of the fins is 0.08mm higher than the height of the seal, leaving a certain deformation space for the fins, so that it has enough support; the material of the fins is titanium alloy, and the thickness is 0.1mm;

[0051] Wherein, by weight, the solder includes the following components:

[0052] Ni 40.0; Cr 6.0; B 4.0; Mn 5.0; Si 10.0; Cu 3.0; Fe 25.0; Mo 3.0; W 2.0; Ta2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com