Riveting equipment and method for home appliance panel

A riveting and panel technology, applied in metal processing equipment, storage devices, feeding devices, etc., can solve the problems of weak solder joints, unfavorable fast and accurate positioning, and low connection strength, so as to improve reliability and connection strength, avoid Solder joints are weak and the effect of improving riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

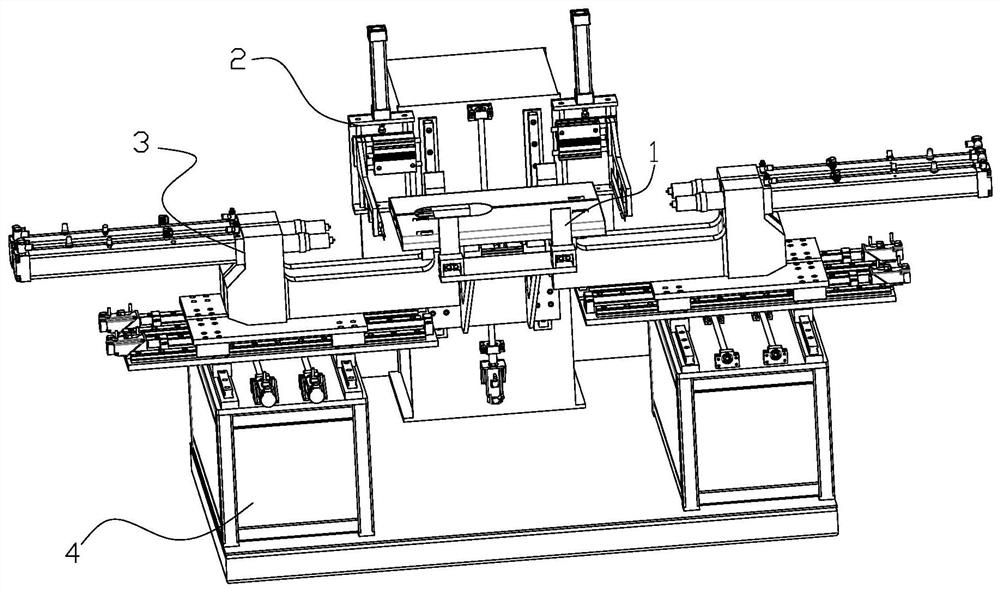

[0040] like figure 1 Shown is a home appliance panel riveting device, which includes a bottom plate positioning mechanism 1 , a side plate positioning mechanism 2 , a riveting mechanism 3 and a frame 4 . The base plate positioning mechanism 1 , the side plate positioning mechanism 2 and the riveting mechanism 3 are all fixed on the frame 4 . The two riveting mechanisms 3 are fixed to the upper end surface of the frame 4 and are located on the left and right sides of the frame 4 respectively. The bottom plate positioning mechanism 1 is fixed on the front end surface of the middle column of the rack 4 , and the two side plate positioning mechanisms 2 are fixed above the bottom plate positioning mechanism 1 and are located on the left and right sides of the bottom plate positioning mechanism 1 respectively.

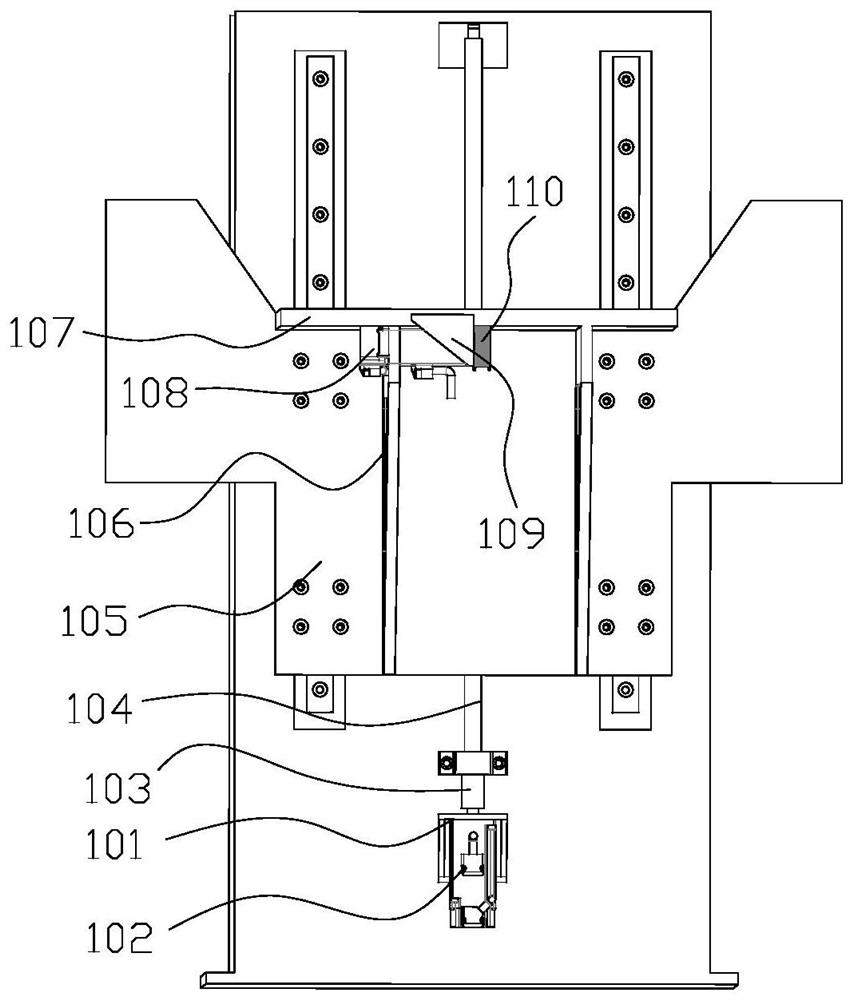

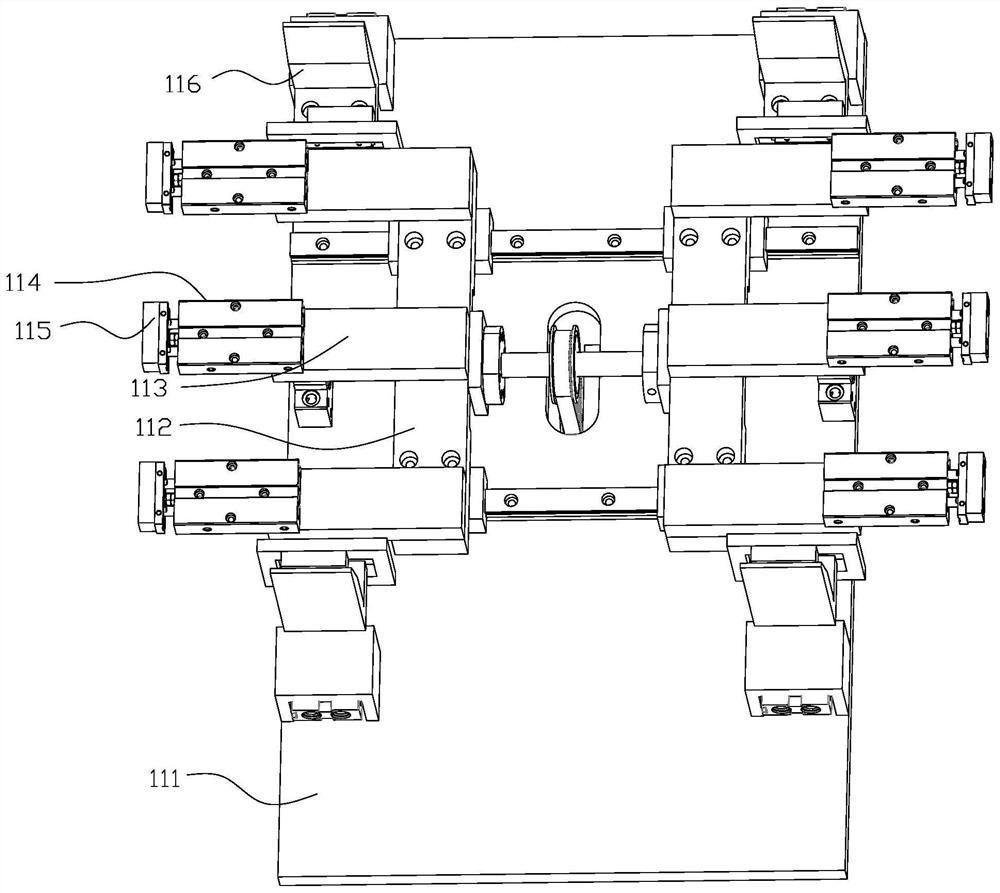

[0041] like figure 2 image 3 As shown, the baseplate positioning mechanism 1 includes a baseplate first drive motor 101, a baseplate first drive motor seat 102, a coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com