Flue gas treatment equipment for rubber processing

A flue gas treatment and equipment technology, applied in the field of flue gas treatment equipment for rubber processing, can solve life problems, reduce filtration effect, soil pollution and other problems, improve replacement safety and operation efficiency, ensure filtration and purification effect, ensure Air Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

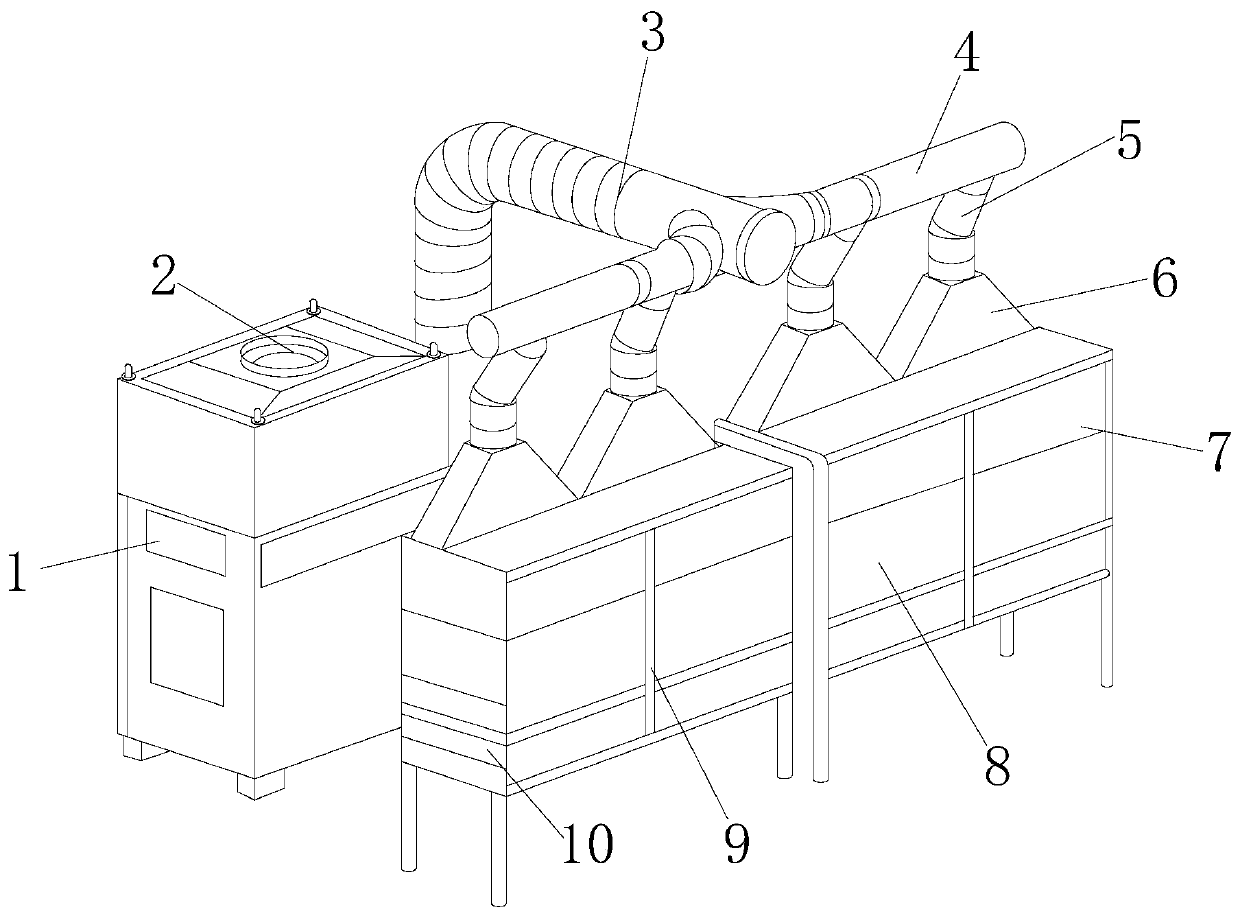

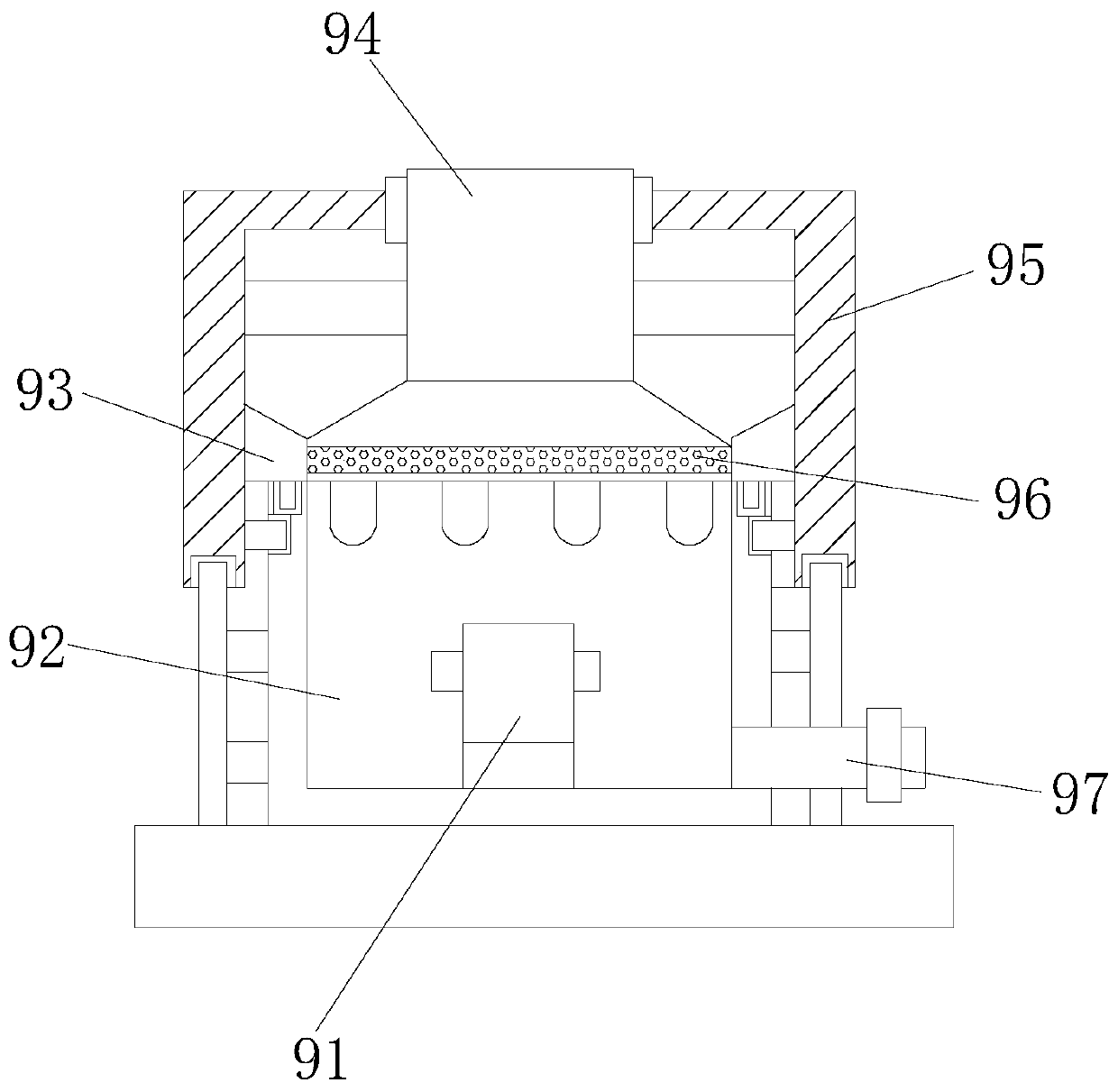

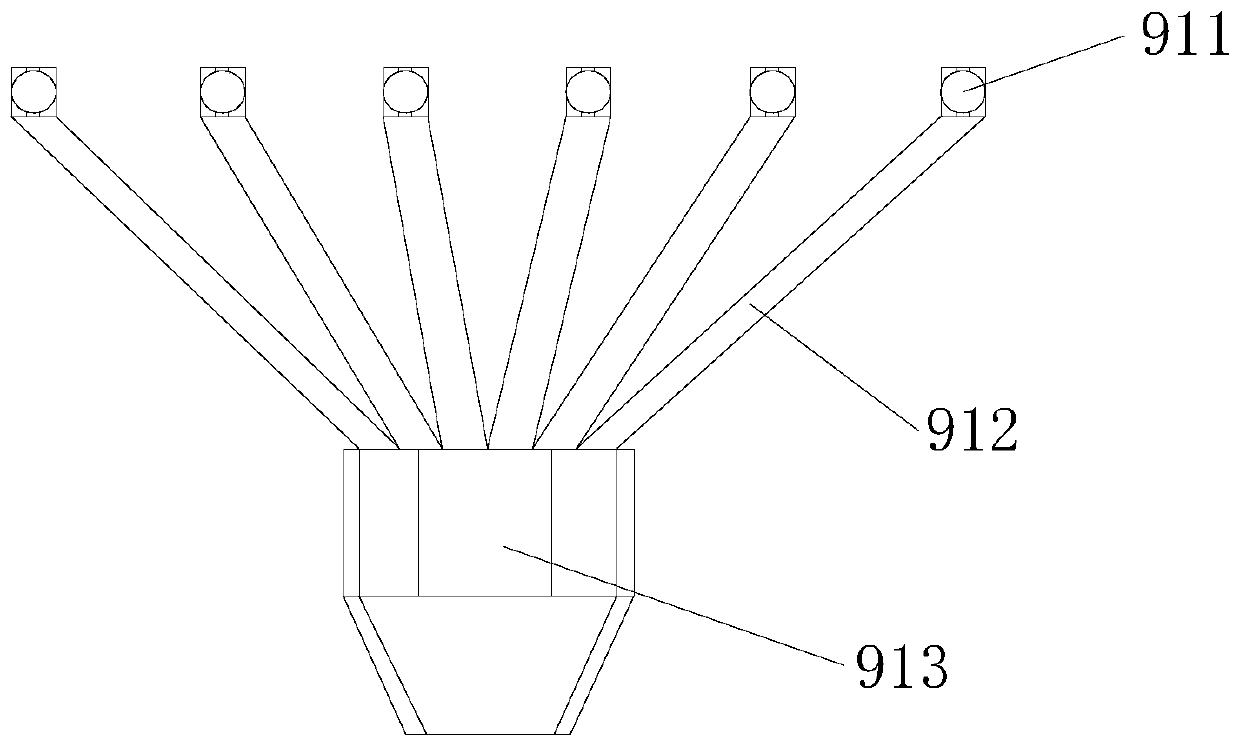

[0032] see figure 1 , the present invention provides a technical solution: a flue gas processing equipment for rubber processing, the structure of which includes a chassis 1, a smoke inlet 2, a first smoke inlet pipe 3, a second smoke inlet pipe 4, an air guide pipe 5, a dust removal device 6, processor 7, purifier 8, dosing device 9, replacement device 10, the top of the cabinet 1 is provided with a smoke inlet 2, and the smoke inlet 2 communicates with the bottom of the first smoke inlet pipe 3, so The front end of the first smoke inlet pipe 3 is connected to the middle position of the second smoke inlet pipe 4, and the second smoke inlet pipe 4 is transversely connected to the first smoke inlet pipe 3, and the lower end of the second smoke inlet pipe 4 is provided with Four air guiding pipes 5, the air guiding pipes 5 are equidistantly connected to the lower end of the second smoke inlet pipe 4, the bottom of the air guiding pipes 5 is connected to a dust collector 6, and ...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a flue gas processing equipment for rubber processing, the structure of which includes a chassis 1, a smoke inlet 2, a first smoke inlet pipe 3, a second smoke inlet pipe 4, an air guide pipe 5, a dust removal device 6, processor 7, purifier 8, dosing device 9, replacement device 10, the top of the cabinet 1 is provided with a smoke inlet 2, and the smoke inlet 2 communicates with the bottom of the first smoke inlet pipe 3, so The front end of the first smoke inlet pipe 3 is connected to the middle position of the second smoke inlet pipe 4, and the second smoke inlet pipe 4 is transversely connected to the first smoke inlet pipe 3, and the lower end of the second smoke inlet pipe 4 is provided with Four air guiding pipes 5, the air guiding pipes 5 are equidistantly connected to the lower end of the second smoke inlet pipe 4, the bottom of the air guiding pipes 5 is connected to a dust collector 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com