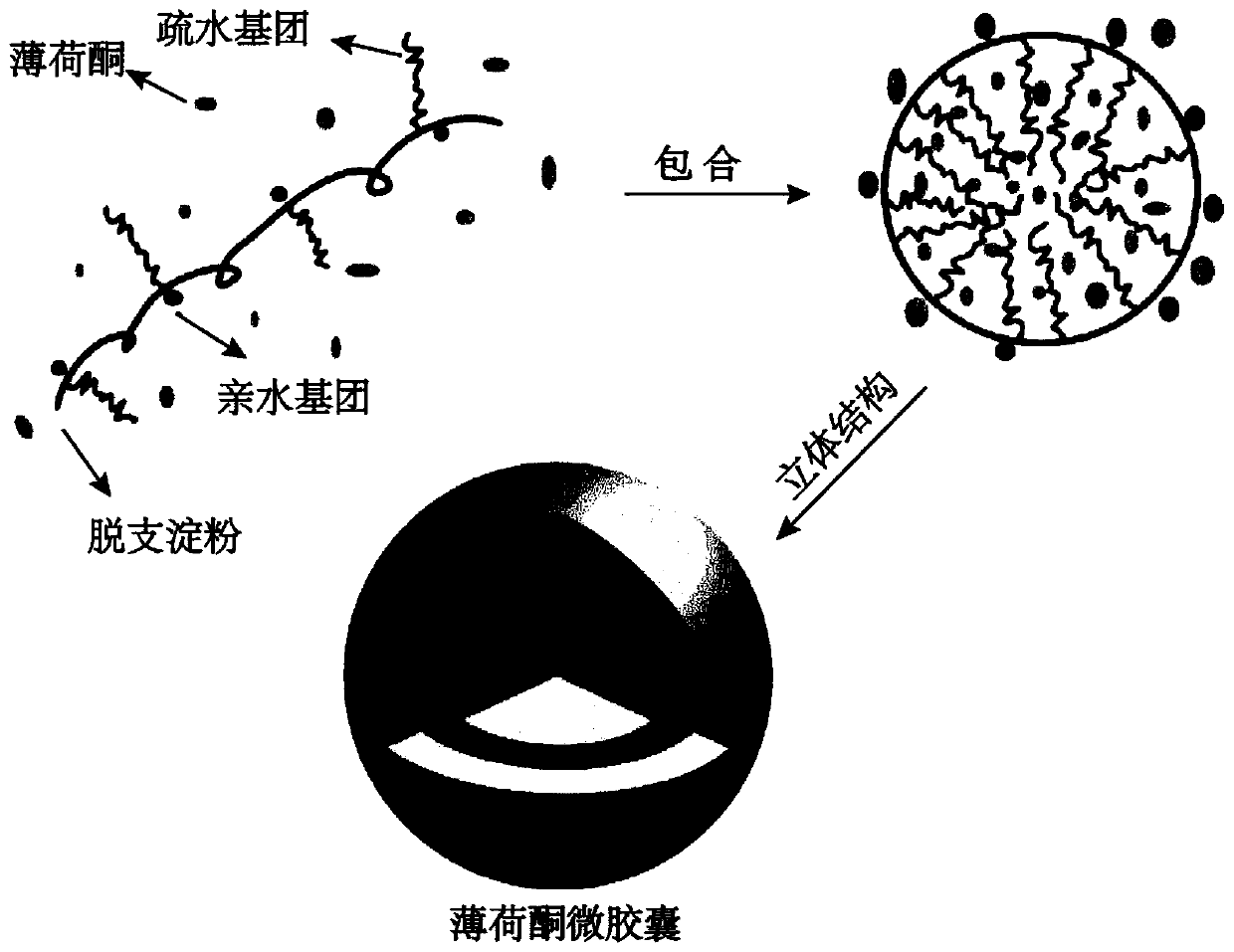

Preparation method of menthone microcapsule and application of menthone microcapsule in chewing tobacco

A technology of menthone and microcapsules, applied in the field of preparation of menthone microcapsules, can solve problems such as bad taste of tobacco, reduce people's sense of experience, etc., and achieve the effects of high acceptance, increased aroma, and strong mint taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

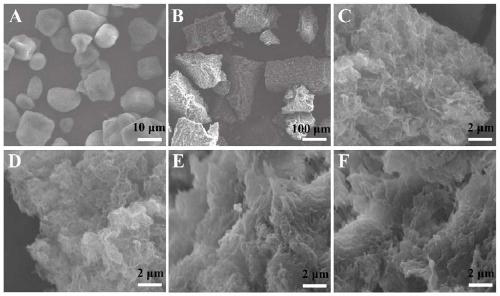

Image

Examples

Embodiment 1

[0034] A preparation method of menthone microcapsules and its application in chewing tobacco, the specific steps are:

[0035] (1) Preparation of debranched starch:

[0036] Take a certain amount of waxy cornstarch (dry basis), and use a phosphate buffer solution with a pH value of 5 to make starch milk with a mass concentration of 15%, and then stir and gelatinize at 100°C for 40min. After the gelatinization is completed, set the temperature to Lower to 60°C, add pullulanase (1000ASPU / g), the weight ratio of gelatinized starch to enzyme is 50:1, and keep stirring for 10h, then centrifuge (3000r / min, 5min) the supernatant The solution was heated to 95°C for 20 minutes to inactivate the enzyme activity, and finally cooled to room temperature of 25°C, then placed in a refrigerator at 4°C for 8 hours, and then freeze-dried for 48 hours to obtain demyelinated starch.

[0037] (2) Preparation of Menthone Microcapsules:

[0038]Prepare 2mg / mL debranched starch solution, heat it at...

Embodiment 2

[0051] A preparation method of menthone microcapsules and its application in chewing tobacco, the specific steps are:

[0052] (1) Preparation of debranched starch:

[0053] Take a certain amount of waxy cornstarch (dry basis), use a phosphate buffer solution with a pH value of 5 to make starch milk with a mass concentration of 20%, and then stir and gelatinize at 100°C for 30min. After the gelatinization is completed, set the temperature to Lower to 55°C, add pullulanase (1000ASPU / g), the weight ratio of gelatinized starch to enzyme is 55:1, and keep stirring for 10h, then centrifuge (3000r / min, 5min) supernatant The solution was heated to 90°C for 20 minutes to inactivate the enzyme activity, and finally cooled to room temperature of 25°C, then placed in a refrigerator at 4°C for 10 hours, and then freeze-dried for 36 hours to obtain demyelinated starch.

[0054] (2) Preparation of Menthone Microcapsules:

[0055] Prepare a 3 mg / mL debranched starch solution, heat it at 10...

Embodiment 3

[0059] A preparation method of menthone microcapsules and its application in chewing tobacco, the specific steps are:

[0060] (1) Preparation of debranched starch:

[0061] Take a certain amount of waxy cornstarch (dry basis), and use a phosphate buffer solution with a pH value of 5 to make starch milk with a mass concentration of 30%, and then stir and gelatinize at 100°C for 40min. After the gelatinization is completed, set the temperature to Lower to 65°C, add pullulanase (1000ASPU / g), the weight ratio of gelatinized starch to enzyme is 60:1, and keep stirring for 15h, then centrifuge (3000r / min, 5min) supernatant The solution was heated to 100°C for 30 minutes to inactivate the enzyme activity, and finally cooled to room temperature of 25°C, then placed in a refrigerator at 4°C for 10 hours, and then freeze-dried for 72 hours to obtain debranched starch.

[0062] (2) Preparation of Menthone Microcapsules:

[0063] Prepare a 4mg / mL debranched starch solution, heat it at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com