Collision safety detection device for fuel cell bus and control method of collision safety detection device

A safety detection, fuel cell technology, applied in fuel cells, electromagnetic measurement devices, measurement devices, etc., can solve the problems of secondary accidents, large vehicle size, shortening the service life of fuel cell stacks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

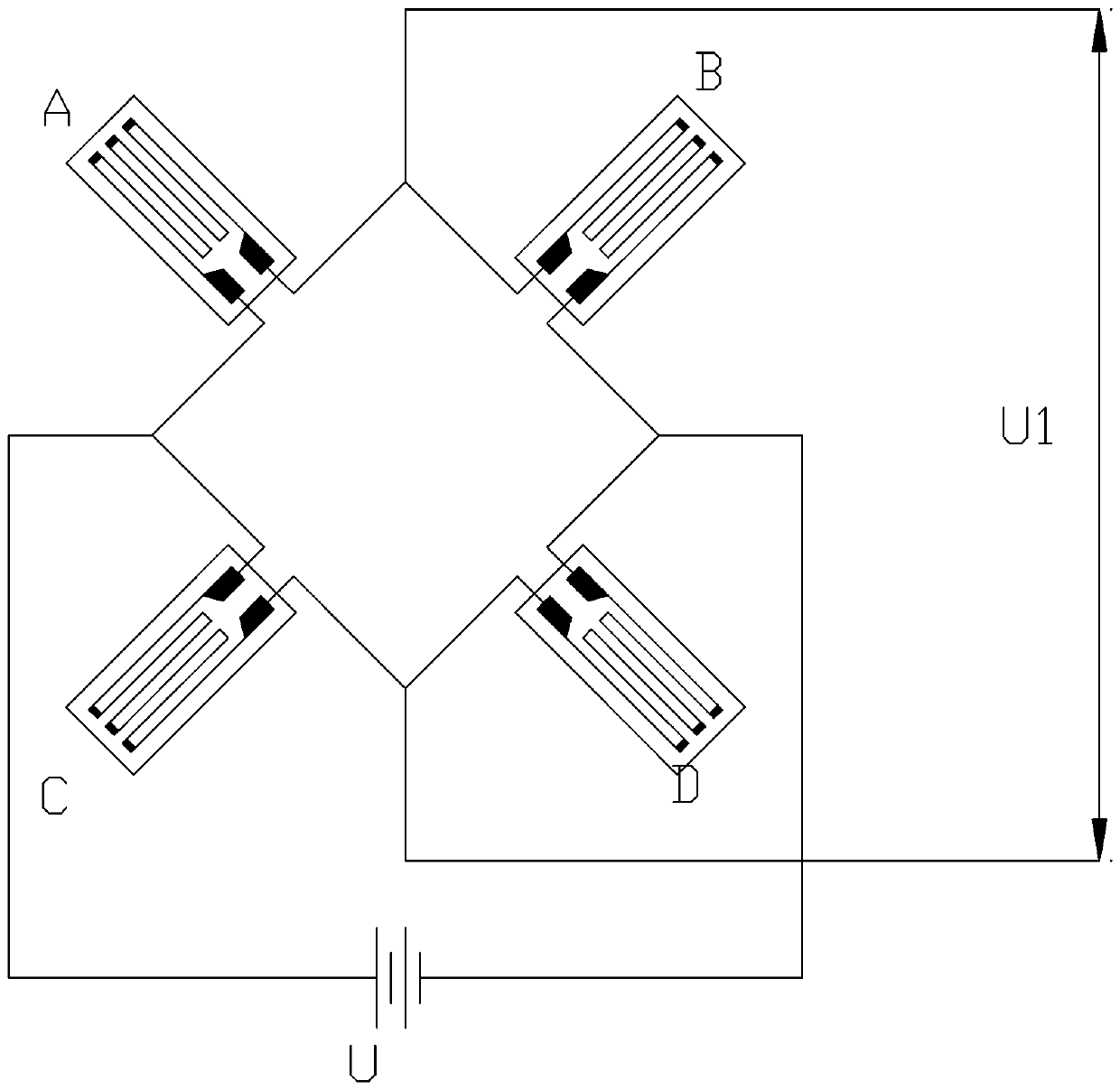

[0047] like Figure 1 to Figure 5 As shown, a fuel cell passenger car collision safety detection device includes a hydrogen supply system arranged on the roof and a fuel cell system arranged behind the roof or in the high-pressure compartment on the back of the roof. The hydrogen supply system is connected through a stainless steel hydrogen pipe. The various components of the hydrogen supply system are connected and set. The stainless steel hydrogen pipes of the hydrogen supply system and the reference surfaces of the fuel cell system are equipped with resistance strain gauges as sensors. The stainless steel hydrogen pipes of the hydrogen supply system and the electromagnetic of the hydrogen supply system A test point is set on the valve and the sensor every set distance s, and each test point is respectively pasted with one of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com