Drying equipment for grains and drying method thereof

A technology for drying equipment and grain, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of difficult turning, grain cannot be dried on time, and single function, etc., and achieves the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

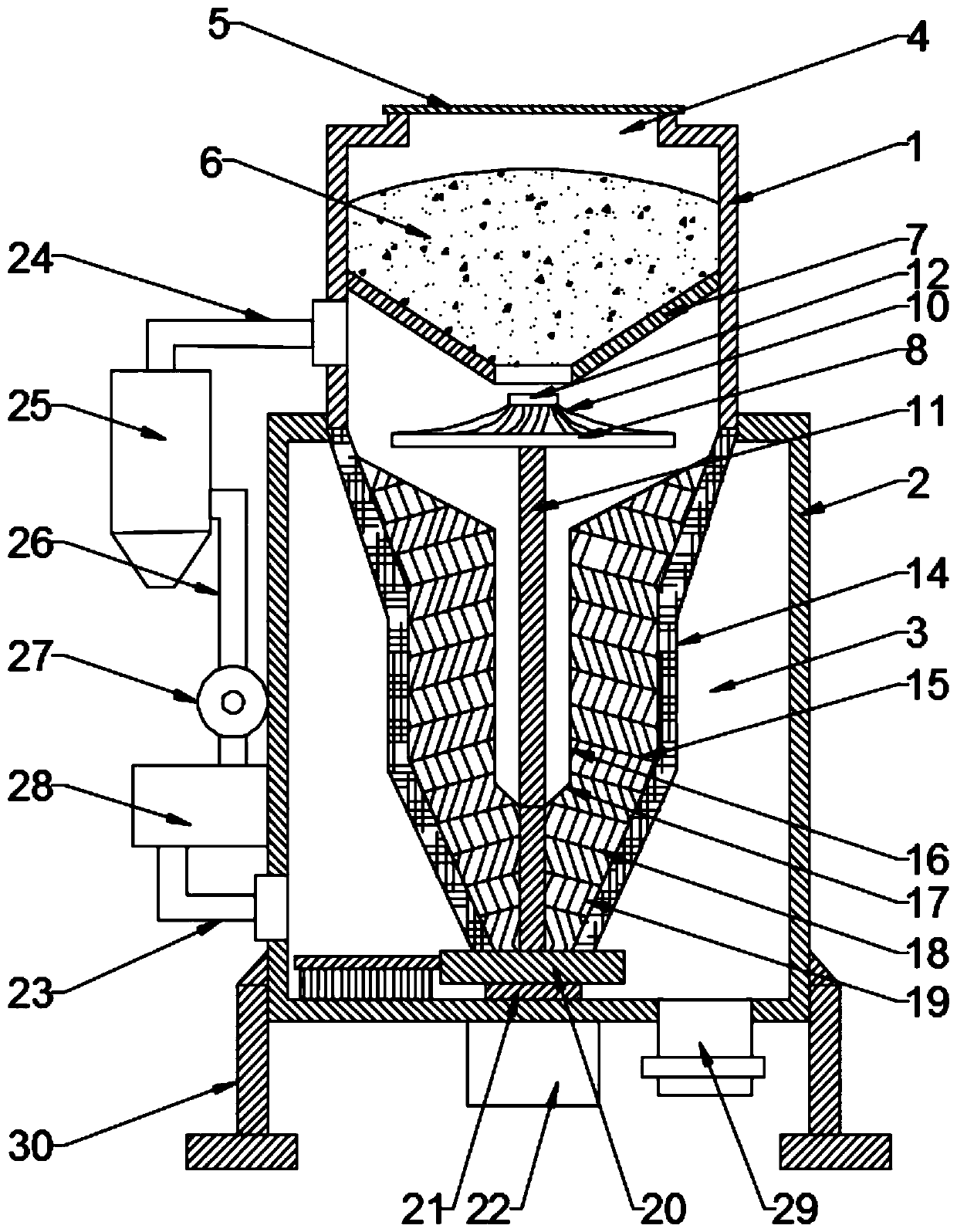

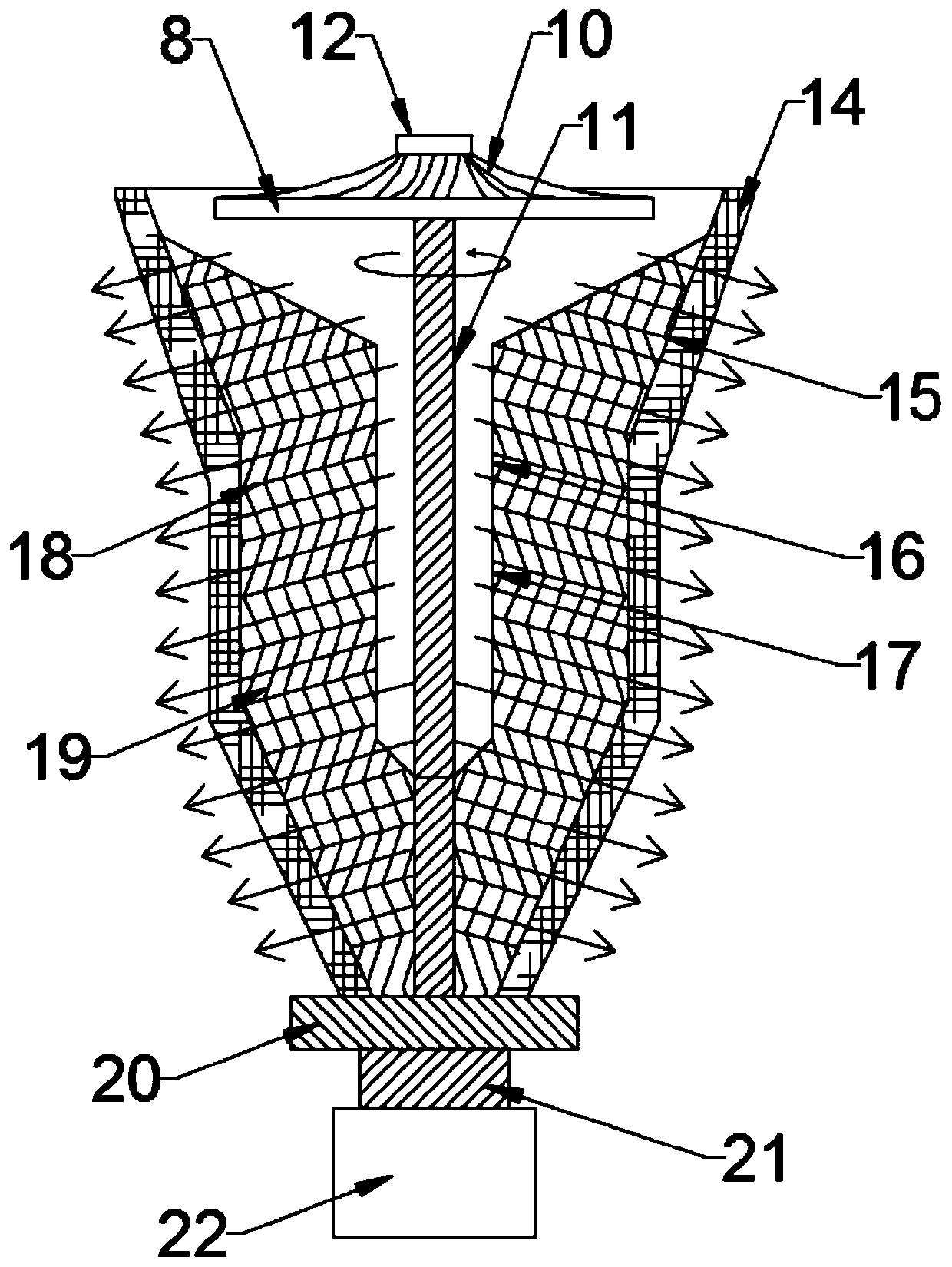

[0034] See Figure 1 ~ Figure 3 , A drying equipment for grain, including a storage box 1, a drying box 2 and a rotary drying assembly 3. The storage box 1 is installed above the drying box 2, and the drying box 2 A rotary drying assembly 3 is installed inside. During the drying operation, the grain in the storage box 1 falls into the rotary drying assembly 3, and is discharged after being heated and dried in the drying box 2;

[0035] The top of the storage box 1 is provided with a grain adding port 4, and a sealing cover 5 is installed above the grain adding port 4. The inside of the storage box 1 is set as a grain storage cavity 6, and the bottom of the grain storage cavity 6 is provided with a hopper 7. The guide hopper 7 is fixed on the inner wall of the storage box 1; when the grain needs to be added to the grain storage cavity 6, only the sealing cover 5 needs to be opened, and the grain is poured from the grain adding port 4 into the grain storage cavity 6 And close the ...

Embodiment 2

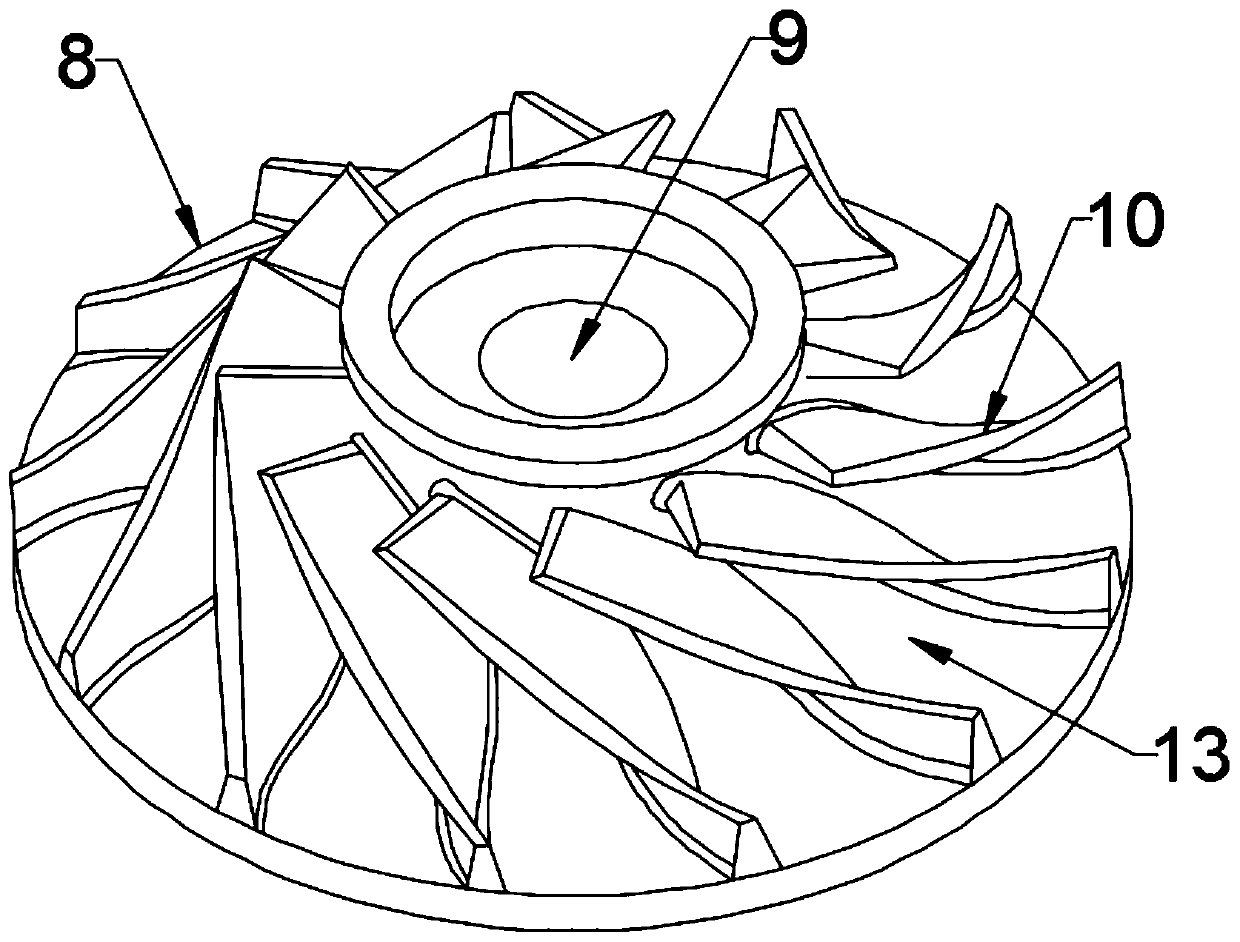

[0043] A drying method of a drying device for grains is realized by the drying device for grains described in Embodiment 1. See Figure 1 ~ Figure 3 As shown, the storage box body 1 and the drying box body 2 are connected to form a closed grain drying equipment, and it is advantageous for the rotary drying assembly 3 installed in the drying box body 2 to fall into the rotary drying assembly 3 The grain inside is fully dispersed and discharged by centrifugation. The centrifugal rotating feed wheel 8 and the drying grid 15 are used to disperse the grain and fully contact with the hot air flowing from the bottom up to realize the grain drying operation.

[0044] A drying method for drying equipment for grain, the specific method includes the following steps:

[0045] Step 1. Start the cyclone dust collector 25, fan 27 and heating box 28 on the circulation pipe 26 to adjust the temperature in the storage box 1 and the drying box 2 to 55-75°C;

[0046] Step 2: Start the motor 22 to work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com