An automatic early warning and judgment method for oil leakage in the hydraulic system of continuous casting machine

A hydraulic system and automatic early warning technology, applied in the direction of fluid pressure actuation system safety, fluid pressure actuation device, mechanical equipment, etc., can solve the lack of control precision of continuous casting machine, continuous casting machine roll gap out of control, a large amount of inflow of secondary cooling water Circulatory system and other problems to achieve the effect of shortening the positioning and disposal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

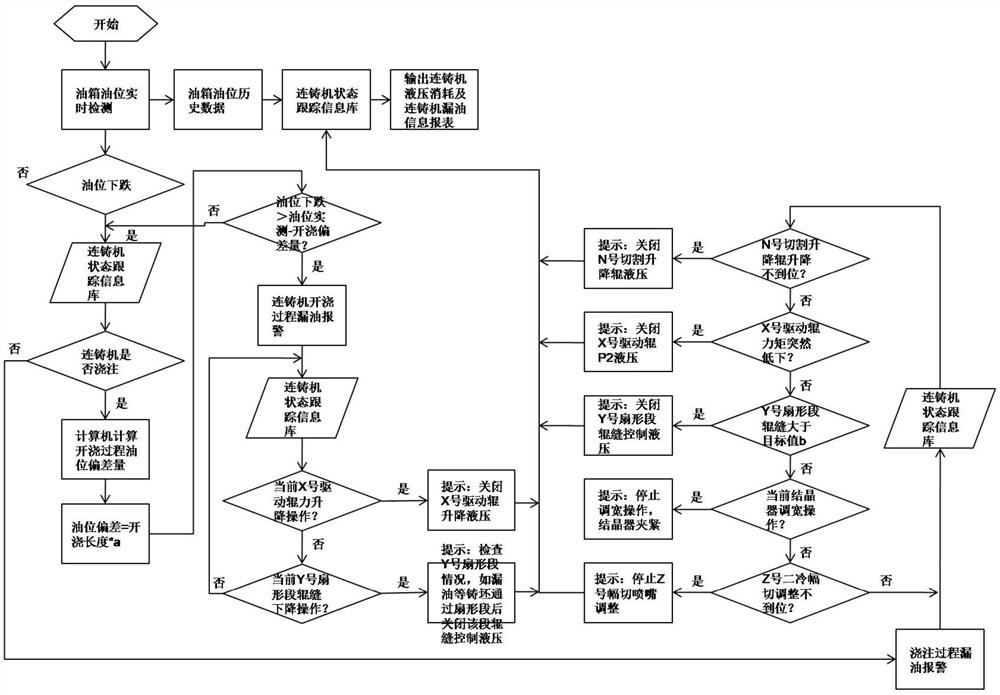

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] There are many user points in the hydraulic system of the continuous casting machine, but the function of each user point is nothing more than to provide equipment power to achieve a certain goal. For example, for the hydraulic system, the purpose of the hydraulic system is to control the roll gap to the target position. For the driving roller of the continuous casting machine, the hydraulic pressure is to provide a certain pressure to make the driving roller press the casting slab tightly, and under the control of the electric device, the casting slab can obtain the power of continuous and stable operation. Therefore, the automatic early warning and judging method of the present invention will utilize various parameters during the operation of these devices, and in combination with the variation of the fuel tank (to eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com