An electronic water pump capable of automatic gas detection and exhaust

An electronic water pump, automatic technology, used in the cooling of the engine, the components of the pumping device for elastic fluid, the pump, etc., can solve the problem of no exhaust device, etc., to reduce the maintenance cost of the system, avoid the idling of the water pump, shorten the The effect of filling and venting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

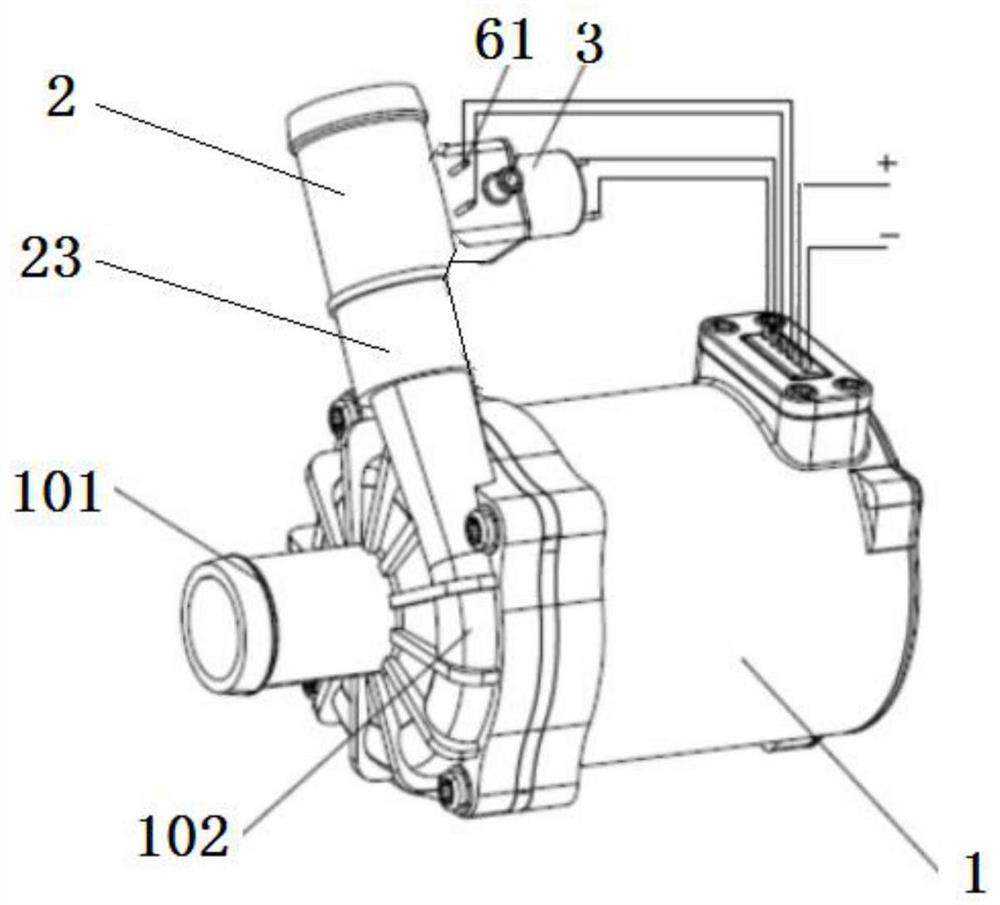

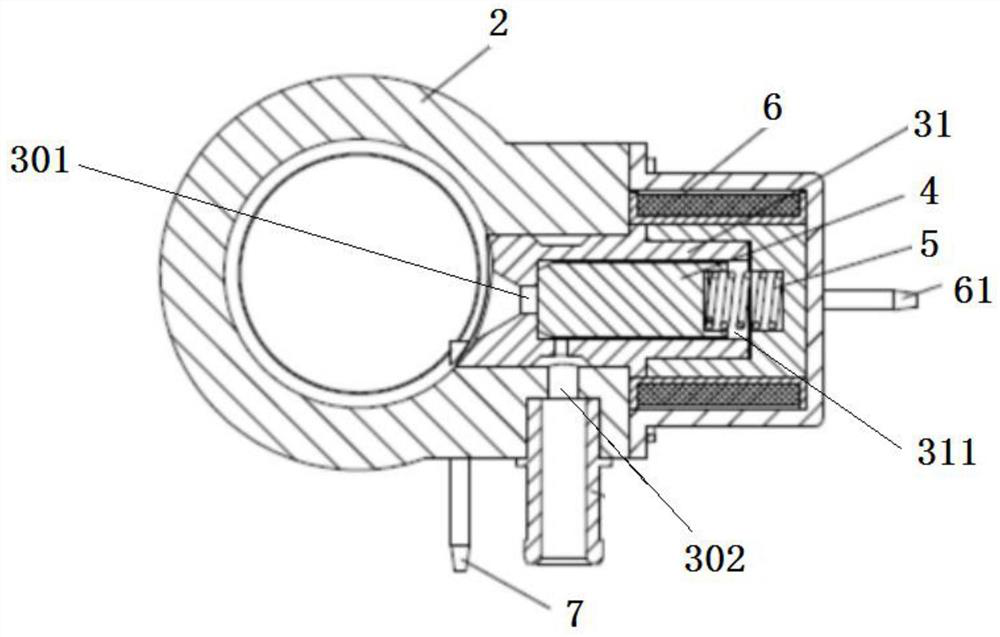

[0023] An electronic water pump capable of automatic gas detection and exhaust, as shown in the figure, includes a water pump body 1, the water pump body 1 is provided with a water inlet 101 and a water outlet 102, and the water outlet 102 is connected with a water outlet pipe 2, and the water outlet pipe 2 An exhaust chamber 3 communicating with the water outlet pipe 2 is arranged on the top, one end of the exhaust chamber is defined as its left end, the other end of the exhaust chamber 3 is defined as its right end, and the left end of the exhaust chamber 3 is provided with an outlet pipe 2 communicated with it. The air inlet 301, the side wall near the left end of the exhaust chamber 3 is also provided with an air outlet 302, the movable iron 4 that can move left and right is installed in the exhaust chamber 3, and the movable iron 4 moves in the exhaust chamber 3 and controls the air intake. The connection between the air port 301 and the air outlet 302 also includes a spri...

Embodiment 2

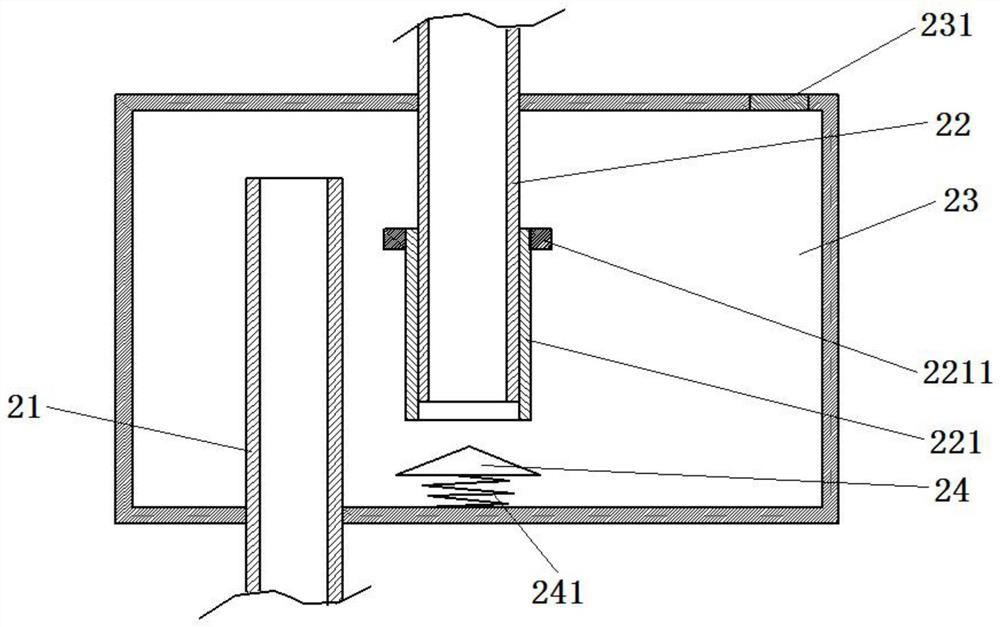

[0031] The difference from Embodiment 1 is that the water outlet pipe 2 includes a first pipe 21 and a second pipe 22, and also includes a water storage chamber 3, one end of the first pipe 21 communicates with the water outlet 102, and the other end of the first pipe 21 is formed by Insert the upper part of the water storage and gas collection chamber 23 from bottom to top, the exhaust chamber 3 is arranged on the second pipe 22, the lower end of the second pipe 22 is inserted into the bottom of the water storage and gas collection chamber 23 from top to bottom, and the water storage and gas collection chamber 23 A valve 231 is provided on the upper top surface of the valve, and the upper port of the first pipe 21 is higher than the lower port of the second pipe 22 .

[0032] Through the design of the water storage and gas collection chamber 3, the gas can be pre-excluded, and after being processed by the exhaust chamber 3, the gas can be discharged more accurately.

[0033] ...

Embodiment 3

[0035] The difference from Embodiment 2 is that it also includes a sealing plug 24 installed in the water storage and air collection chamber 23 and located below the second pipe 22, and also includes a sealing spring 241 fixed on the inner wall of the lower end of the water storage and air collection chamber 23, sealing The spring 241 is affixed to the lower surface of the sealing plug 24 , and the sealing plug 24 is lifted up by the action of the sealing spring 241 and seals the lower port of the second tube 22 .

[0036]The lower end of the second tube 22 is also sleeved with a telescopic tube 221 that can slide up and down along the second tube 22. The inside of the telescopic tube 221 is tightly bonded to the outer wall of the second tube 22. A buoyancy block 2211 is installed on the top of the telescopic tube 221. , the buoyancy block 2211 controls the expansion and contraction of the telescopic tube 221 through its own position in the water storage and air collection cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com