Double grouphead of beverage brewing mechanism

A brewing and beverage technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of low utilization rate of beverage brewing mechanism equipment, complex components and increased equipment costs, etc., to achieve increased beverage brewing Output value and equipment utilization rate, component volume miniaturization, and the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

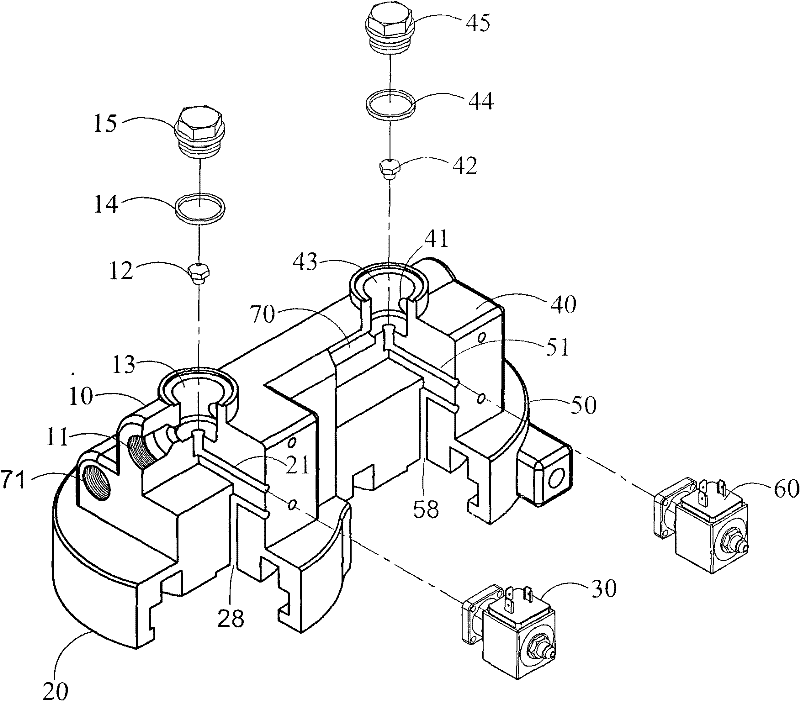

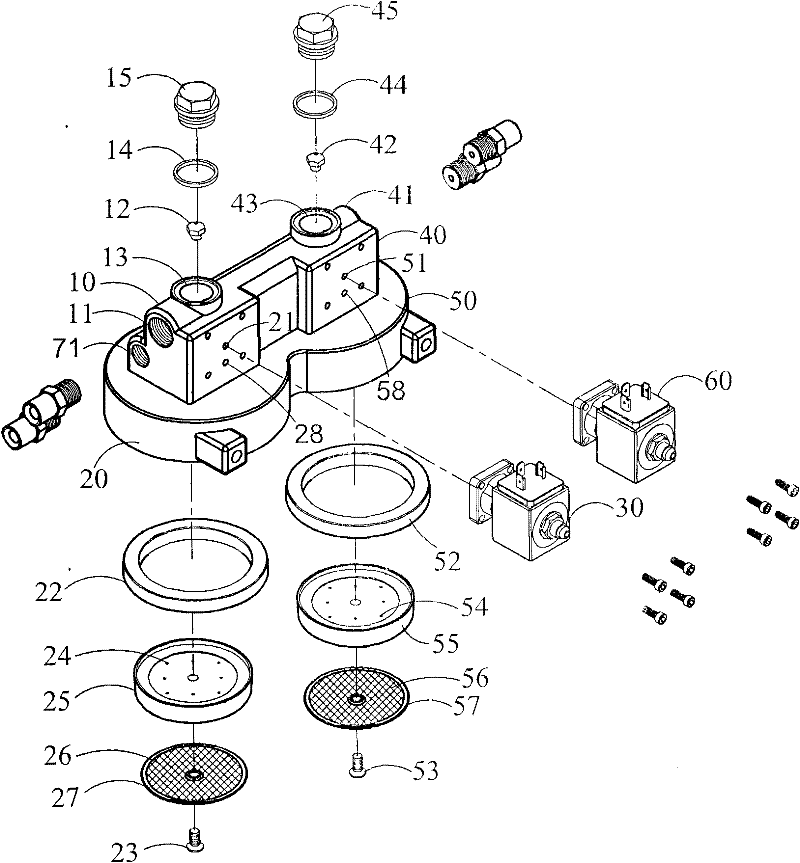

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] Please also see Figure 1 to Figure 3 , the dual-parallel brewing head of the beverage brewing mechanism provided by the present invention includes: a first flow guide seat 10, which is provided with a water inlet hole 11, so as to receive the hot water provided by the beverage brewing mechanism / steam water flow; a first filter cup connecting seat 20 communicates with the first water guide seat 10 through a first water outlet channel 21 and its first water channel 28; a first electromagnetic valve 30 is used for passing the electric Control the conduction and disconnection of the first water outlet channel 21 and the first water channel 28; a second flow guide seat 40 communicated with the first flow guide seat 10 through a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com