Control apparatus for hydraulically operated vehicular transmission

A control method and gearbox technology, applied in the direction of engine control, transmission control, and components with teeth, etc., can solve the problem of insufficient hydraulic pressure increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

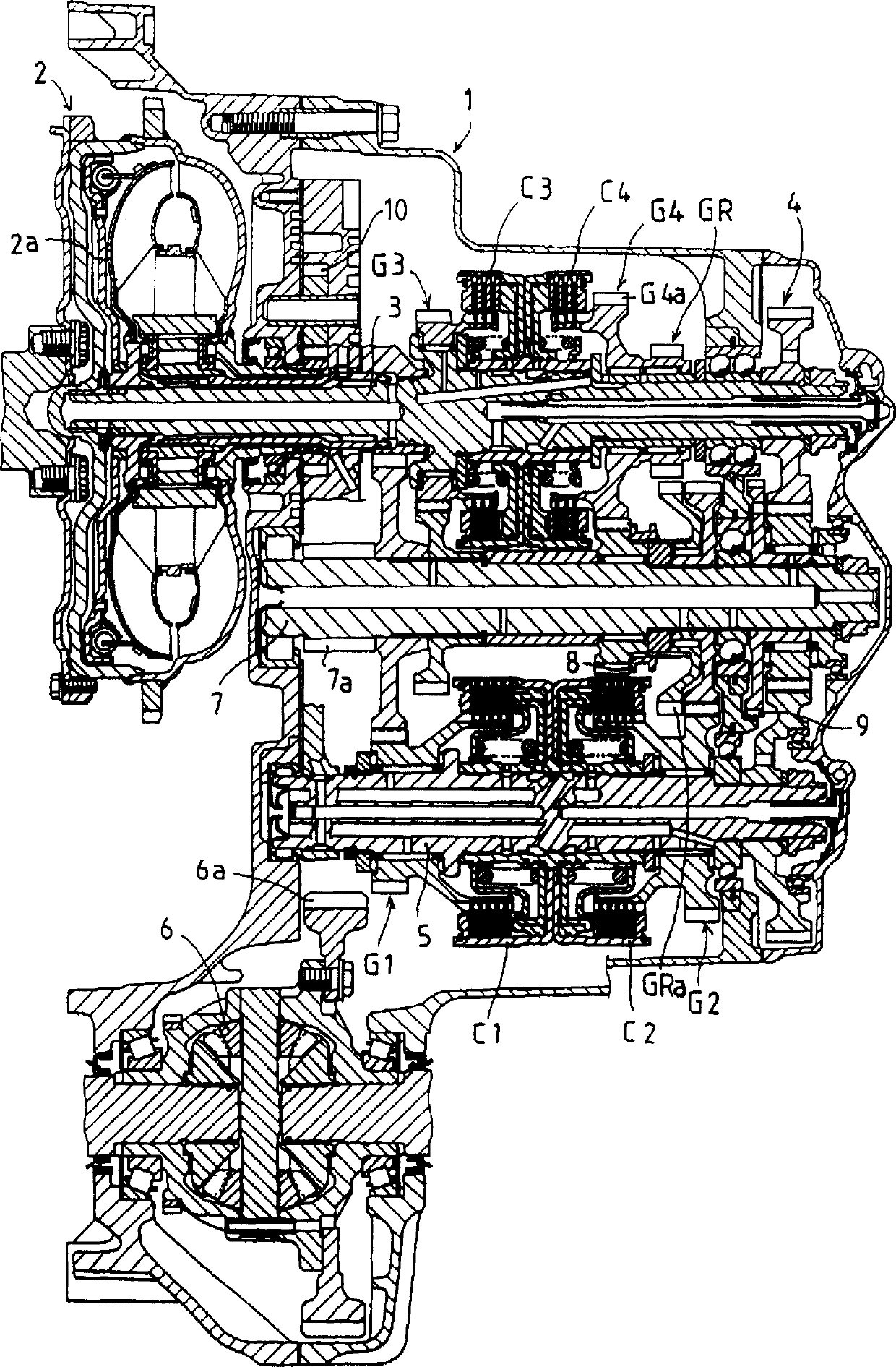

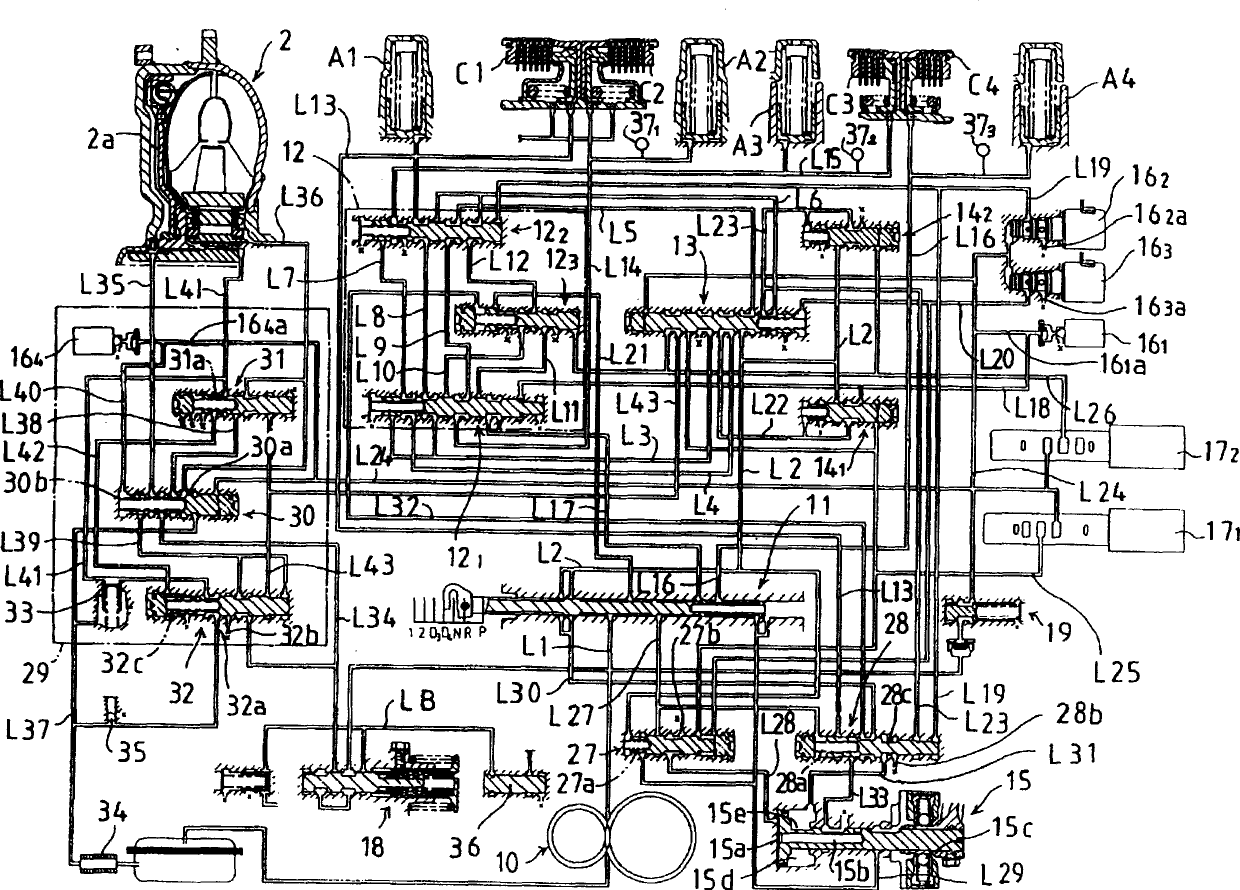

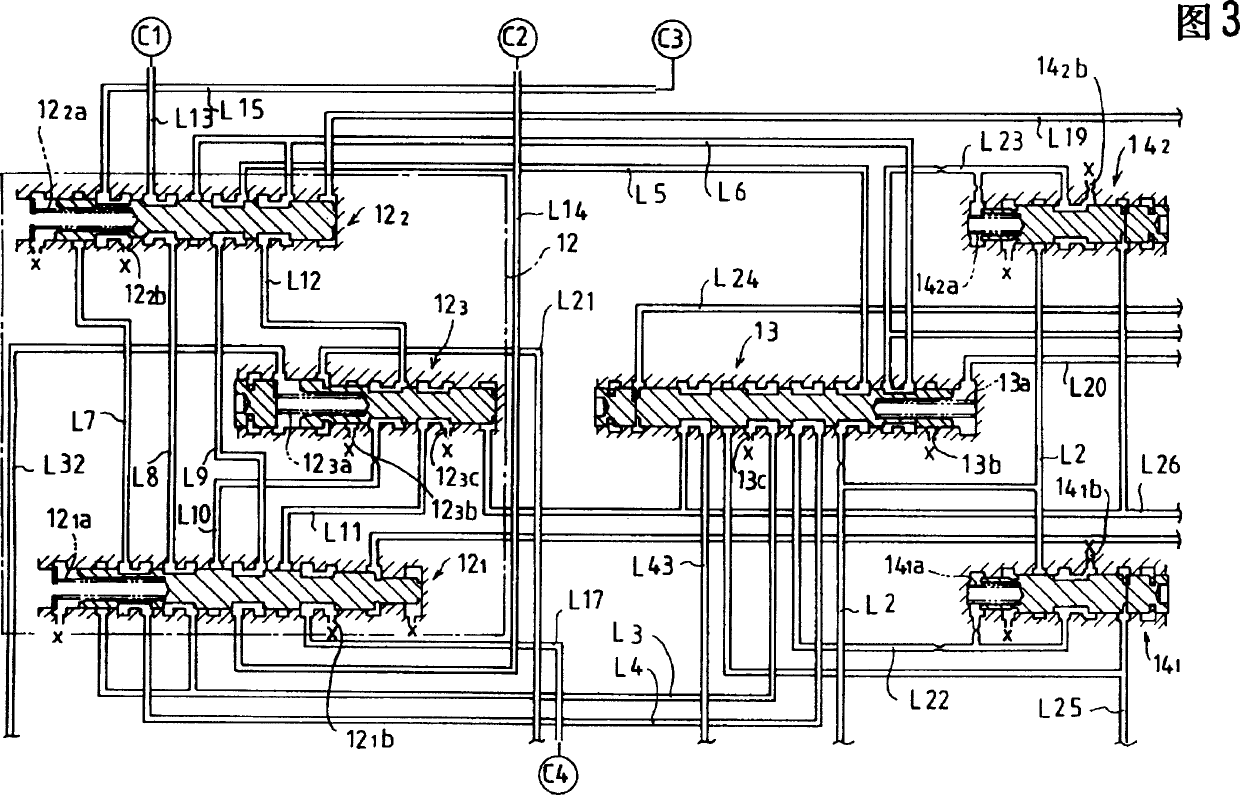

[0023] Referring to FIG. 1, numeral 1 designates a hydraulically operated vehicle transmission for performing speed changes of four forward drive trains and one reverse drive train. The gearbox 1 is equipped with: an input shaft 3, connected to an engine via a torque converter 2; an intermediate shaft 5, always connected to the input shaft 3 via a gear train 4; and an output The shaft 7 has a shaft end output gear 7a meshing with a final gear 6a on a differential 6 connected to drive wheels of a vehicle such as a motor vehicle. In the drawing, the final gear 6a and the output gear 7a are shown separated from each other. This is because the figure is drawn in a developed view, but actually the gears 6a, 7a are meshed with each other.

[0024] A first speed transmission train G1 and a second speed transmission train G2 are provided in parallel between the intermediate shaft 5 and the output shaft 7 . A third-speed gear train G3, a fourth-speed gear train G4, and a reverse gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com