Three-stroke piston pulse internal combustion engine

A technology of internal combustion engine and pulse type, which is applied in the direction of mechanical equipment, machine/engine, etc., can solve the problems that there is no three-stroke piston pulse type internal combustion engine, and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

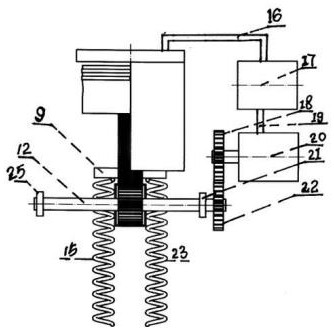

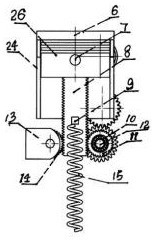

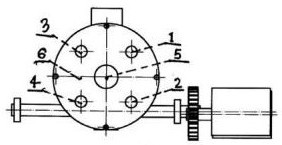

[0017] Such as Figure 1-4 The three-stroke piston pulse internal combustion engine is mainly composed of cylinder, cylinder head 6, piston 26, rack 8, power transmission gear 11, power output shaft 12, piston stroke controller 13, exhaust spring, high-pressure gas storage cylinder 17, air The compressor 20 is composed of; wherein, the piston 26 is connected with the rack 8 through the piston pin 7, the piston 26 covers the cylinder liner 24, and the top of the cylinder liner 24 is equipped with a cylinder head 6, and the upper part of the cylinder head 6 has a component intake valve 1 and a spark plug. 2. The fuel injector 3, the air pressure sensor 4, the exhaust valve 5, and the spring pin 9 pierced in the middle of the rack 8 are respectively connected with the exhaust spring A 15 and the exhaust spring B 23. The tooth grooves on both sides of the rack 8 are meshed with the controller gear 14 and the power transmission gear 11 respectively; the controller gear 14 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com