Plate wall fixing device and fixing method for building

A technology of fixing device and fixing method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of poor stability and poor fixing effect, and achieve the effects of high stability, easy operation and improved construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

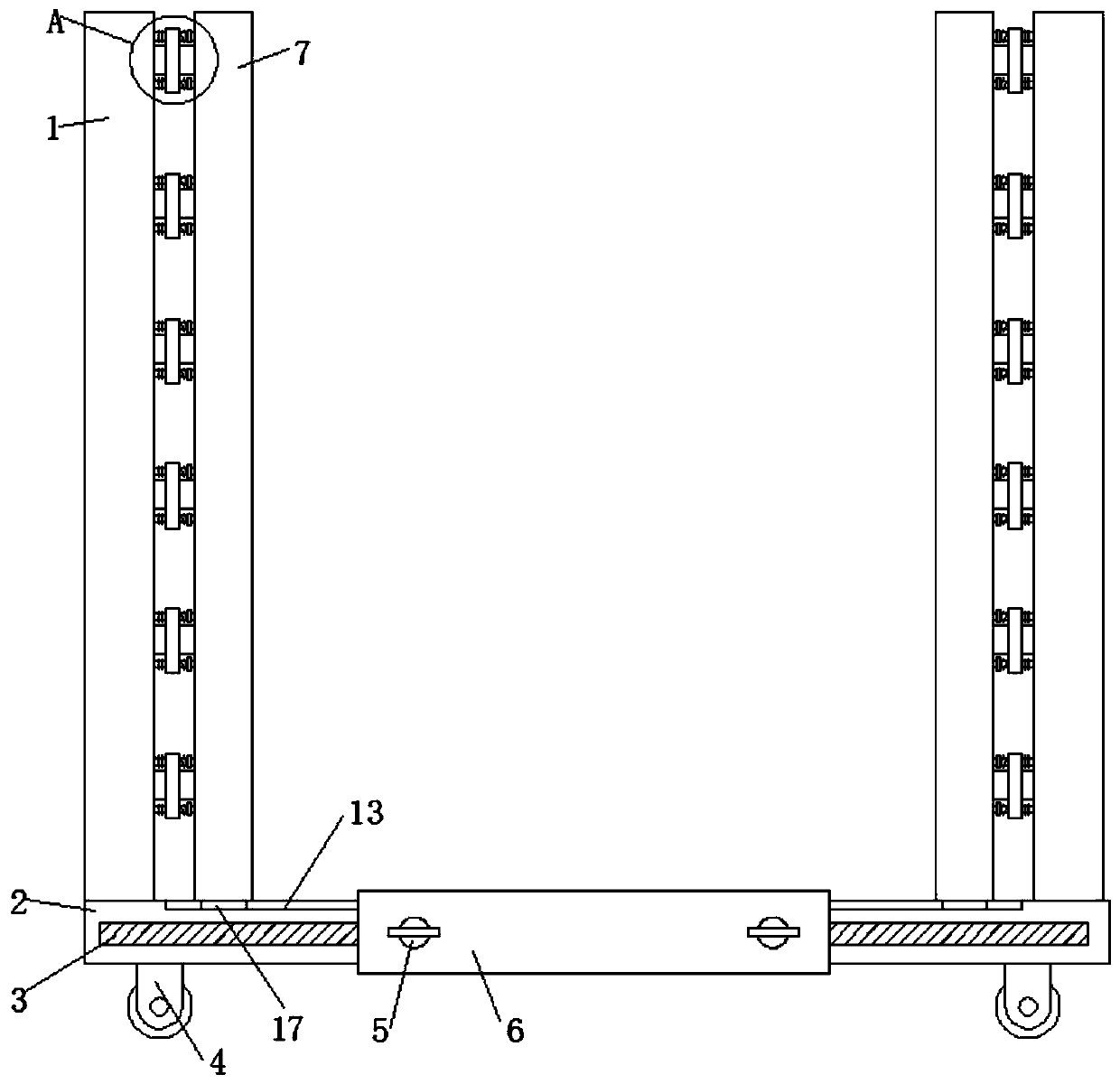

[0037]A building board wall fixing device of this embodiment includes a bottom plate 2, an adjustment base 6 and a buffer mechanism. Two bottom plates 2 are installed slidingly on the left and right sides of the inside of the adjustment base 6 along the horizontal direction, and the inside of the adjustment base 6 is provided with The through slots for the inward and outward telescopic adjustment of the two bottom plates 2 are installed in the through slots of the adjustment base 6 at the ends of the two base plates 2 away from each other, and can slide in the through slots and extend to the outside of the adjustment base 6 . The ends of the upper parts of the two bottom plates 2 away from the adjustment base 6 are vertically installed with a fixed side plate 1 and an installation side plate 7 in sequence, that is, the fixed side plate 1 is installed on the outermost side of the bottom plate 2, and the installation side plate 7 is located between the fixed side plate 1 and the a...

Embodiment 2

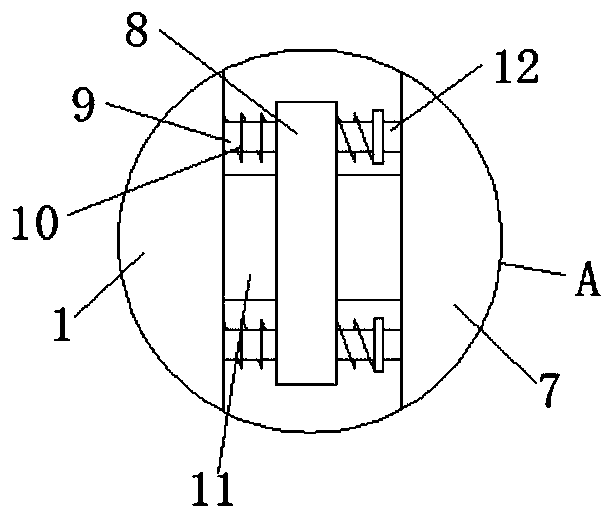

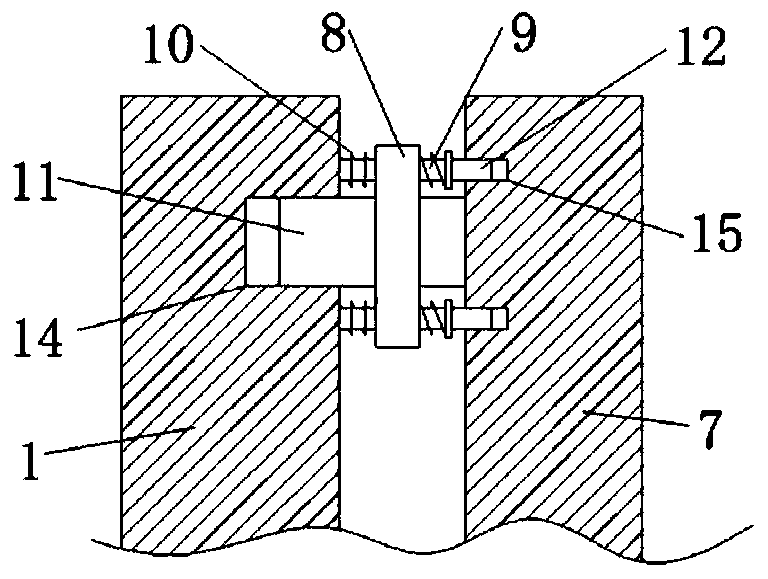

[0039] A kind of building board wall fixing device of this embodiment, its structure is basically the same as that of Embodiment 1, and its main difference is that: the buffer mechanism includes a first insertion rod 11, a sliding rod 9, a sliding block 8 and a buffer spring 10, specifically of, such as figure 2 and image 3 As shown, one end of the first insertion rod 11 is fixed on the installation side plate 7, and the other end is movably inserted into the corresponding first slot 14 provided on the fixed side plate 1, and the first insertion rod 11 and the second The inner wall of a slot 14 is flexibly fitted. The sliding block 8 is fixed on the middle of the first insertion rod 11 along the vertical direction, and moves left and right along with the first insertion rod 11 . by image 3 Take the orientation in the figure as an example, that is, when the first insertion rod 11 is inserted into the first slot 14, the sliding block 8 moves to the left, otherwise, the sli...

Embodiment 3

[0044] A kind of building board wall fixing device of this embodiment, its structure is basically the same as embodiment 2, and its main difference is: as figure 1 As shown, the bottom plate 2 is detachably connected to the adjustment base 6 through the top wire 5, and the installation position of the bottom plate 2 and the adjustment base 6 can be adjusted in time through the setting of the top wire 5, even if the two side panels are installed 7, the distance between them is adjusted, so that the preliminary fixing and clamping operations of the board wall are simple and easy to implement. At the same time, strip-shaped anti-skid lines 3 are provided on the front surfaces of the two bottom plates 2 along the horizontal direction, thereby further improving the installation stability of the board wall fixing.

[0045] Further, the above-mentioned fixed side plate 1 is fixed on the bottom plate 2, and the bottom of the above-mentioned installation side plate 7 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com