Moisture-absorbing sweat-releasing fine denier polyester shell fabric and preparation method thereof

A fine denier polyester, moisture-absorbing and sweat-wicking technology, applied in dyeing, fabric surface trimming, weaving, etc., can solve the problems of slow moisture conduction and moisture release, easy to produce stuffy heat, etc., to enhance moisture-absorbing and sweat-wicking performance, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples.

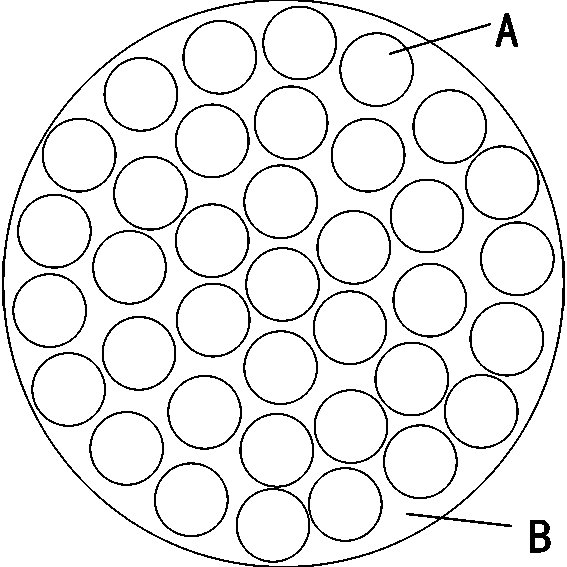

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown moisture-absorbing and sweat-wicking fine-denier polyester fabric is composed of 50D / 24F / 37i sea-island type bicomponent composite polyester filaments, and the composite ratio of the island phase to the sea phase is 80:20. It includes the following steps carried out in sequence:

[0026] (1) Two-for-one twisting: after winding, use one-step elastic two-for-one twisting machine to process the raw materials with two-for-one twisting. The twist degree of two-for-one twisting is 8T / cm, the twist direction is S twist, and the temperature of the hot box is 185°C. , the false twist twist is 3000T / m, the two-for-one twist tension is 0.3~0.35cN / D, and the false twist tension is 0.2~0.25cN / D.

[0027] (2) Sectional warping: the warping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com