A kind of preparation method of antiviral composite polyester fiber

A polyester fiber and anti-virus technology, applied in the field of polyester fiber, can solve problems such as unsatisfactory effects, and achieve the effects of easy industrialization, tight integration, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

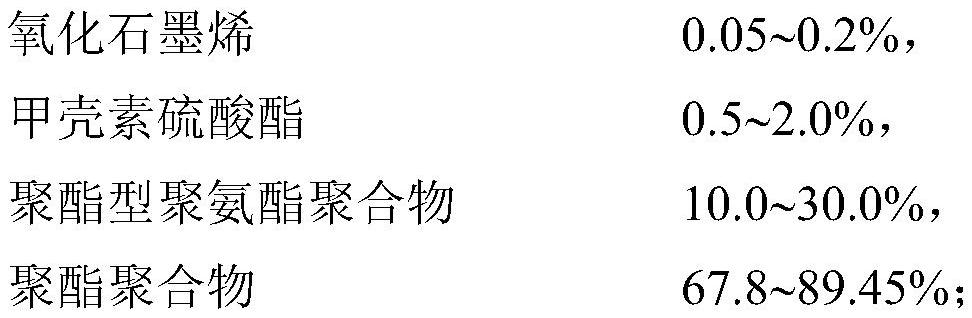

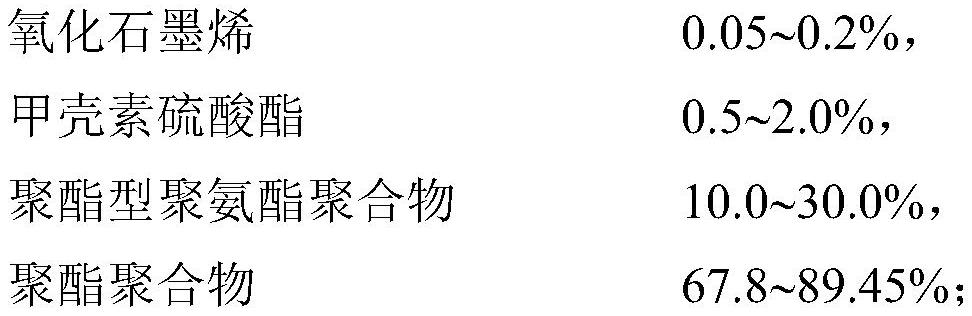

[0029] ① Preparation of sheath material

[0030] 1.1) Dissolve chitin sulfate in dimethylacetamide solution containing 6% lithium chloride, the concentration is controlled at 3%, and the temperature is 70°C.

[0031] 1.2) disperse graphene oxide in dimethylacetamide solvent, and control the concentration at 1%.

[0032] 1.3) Mix the solution prepared in 1.1) and 1.2) with the components of polyester polyurethane, the molar ratio of isocyanate group to hydroxyl group is 1.8, pre-polymerize at 90°C for 45min, after the pre-polymerization is completed, pour into the prepolymer Adding N,N-dimethylacetamide solvent to make a prepolymer solution with a mass percentage concentration of 50%;

[0033] 1.4) The chain extender is N,N-dimethylacetamide solution of ethylenediamine, diethylamine, pentamethylenediamine, the mass percent concentration is 5.0%, wherein, the molar ratio of ethylenediamine to pentamethylenediamine is 90: 10. The consumption of diethylamine is 3000ppm; the chai...

Embodiment 2

[0041] ① Preparation of sheath material

[0042] 1.1) Dissolve chitin sulfate in dimethylacetamide solution containing 6% lithium chloride, the concentration is controlled at 3%, and the temperature is 70°C.

[0043]1.2) disperse graphene oxide in dimethylacetamide solvent, and control the concentration at 1%.

[0044] 1.3) Mix the solution prepared in 1.1) and 1.2) with the components of polyester polyurethane, the molar ratio of isocyanate group to hydroxyl group is 1.8, pre-polymerize at 90°C for 45min, after the pre-polymerization is completed, pour into the prepolymer Adding N,N-dimethylacetamide solvent to make a prepolymer solution with a mass percentage concentration of 50%;

[0045] 1.4) The chain extender is N,N-dimethylacetamide solution of ethylenediamine, diethylamine, pentamethylenediamine, the mass percent concentration is 5.0%, wherein, the molar ratio of ethylenediamine to pentamethylenediamine is 90: 10. The consumption of diethylamine is 3000ppm; the chain...

Embodiment 3

[0053] ① Preparation of sheath material

[0054] 1.1) Dissolve chitin sulfate in dimethylacetamide solution containing 6% lithium chloride, the concentration is controlled at 3%, and the temperature is 70°C.

[0055] 1.2) disperse graphene oxide in dimethylacetamide solvent, and control the concentration at 1%.

[0056] 1.3) Mix the solution prepared in 1.1) and 1.2) with the components of polyester polyurethane, the molar ratio of isocyanate group to hydroxyl group is 1.8, pre-polymerize at 90°C for 45min, after the pre-polymerization is completed, pour into the prepolymer Adding N,N-dimethylacetamide solvent to make a prepolymer solution with a mass percentage concentration of 50%;

[0057] 1.4) The chain extender is N,N-dimethylacetamide solution of ethylenediamine, diethylamine, pentamethylenediamine, the mass percent concentration is 5.0%, wherein, the molar ratio of ethylenediamine to pentamethylenediamine is 90: 10. The consumption of diethylamine is 3000ppm; the chai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com