A kind of preparation method of double size silicon carbide particle hybrid reinforced magnesium matrix composite material

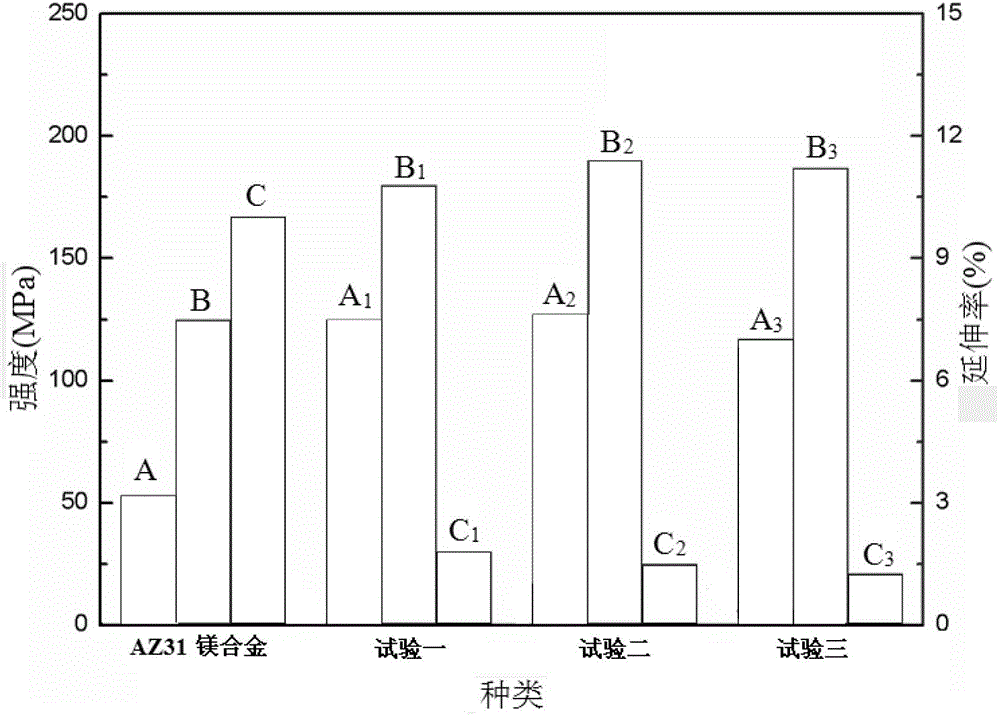

A technology of silicon carbide particles and composite materials, which is applied in the field of preparation of silicon carbide particle-reinforced magnesium-based composite materials, can solve the problems of easy agglomeration of silicon carbide particles, poor compatibility between silicon carbide particles and magnesium alloys, and achieve mechanical properties increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: This embodiment is a preparation method of dual-size silicon carbide particle hybrid reinforced magnesium-based composite material, which is specifically completed according to the following steps: 1. Mixing: first, nanoscale silicon carbide particles and micron-scale carbonized The silicon particles are mixed evenly to obtain double-sized silicon carbide particles; 2. Stirring and ultrasonic dispersion: first, put the double-sized silicon carbide particles into the semi-solid magnesium matrix under the condition of mechanical stirring, and then continue to stir after adding the double-sized silicon carbide particles 4min~6min, and heating up to 700℃~720℃ to obtain a mixed melt, and then ultrasonically disperse the mixed melt under the assistance of ultrasonic waves, and finally obtain a double-sized silicon carbide particle hybrid reinforced magnesium-based composite material through die-casting; steps The volume ratio of nanoscale silicon carbide...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific operation process of the mixing described in step 1 is as follows: Stir and mix nanoscale silicon carbide particles and micron-scale silicon carbide particles under mechanical stirring conditions Evenly, the stirring speed is 1000r / min~1400r / min, and the stirring time is 5min~15min. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring speed of the mechanical stirring described in step 2 is 1000r / min~1400r / min. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com