Water-based UV silver powder coating as well as preparation method and application thereof

A water-based, silver powder technology, applied in the field of coatings, can solve problems such as poor boiling effect, poor metal texture, dull color, etc., and achieve the effects of fast surface drying, improved yield, and good silver powder orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

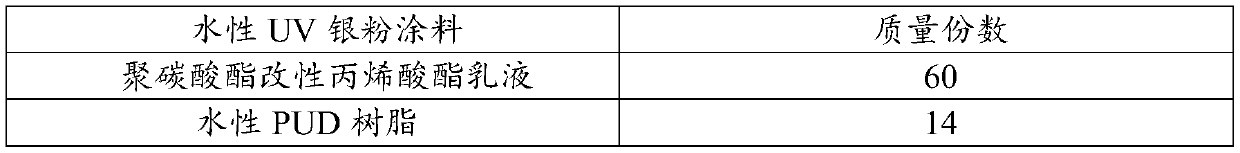

[0064] The water-based UV silver powder coatings in Example 1 are listed in Table 1 in parts by mass.

[0065] Table 1 Composition of waterborne UV silver powder coating components

[0066] Waterborne UV silver powder coating parts by mass Polycarbonate Modified Acrylic Emulsion 60 Waterborne PUD resin 14 D 1.4 Defoamer 0.1 pH regulator 0.2 Dispersant 0.6 Thixotropic agent A 0.4 leveling agent 0.7 matting powder 2 Thixotropic agent B 1.6 silver powder 4 Co-solvent 6 Photoinitiator 3 Deionized water 4

[0067] In this embodiment, there are 0.4 parts of thixotropic agent A and 1.6 parts of thixotropic agent B, and the mass ratio of thixotropic agent A to thixotropic agent B is 1:4.

[0068] The preparation method of above-mentioned waterborne UV silver powder coating is as follows:

[0069] (1) Put the polycarbonate modified acrylate emulsion into the container and stir and disper...

Embodiment 2

[0073] The water-based UV silver powder coatings in Example 2 are listed in Table 2 in parts by mass.

[0074] Table 2 Composition of waterborne UV silver powder coating components

[0075] Waterborne UV silver powder coating parts by mass Polycarbonate Modified Acrylic Emulsion 60 Waterborne PUD resin 14 D 1.4 Defoamer 0.1 pH regulator 0.2 Dispersant 0.6 Thixotropic agent A 1 leveling agent 0.7 matting powder 2 Thixotropic agent B 1 silver powder 4 Co-solvent 6 Photoinitiator 3 Deionized water 4

[0076] Compared with Example 1, the difference in components of this example is 1 part of thixotropic agent A and 1 part of thixotropic agent B, and the mass ratio of thixotropic agent A to thixotropic agent B is 1:1.

[0077] The preparation method of the above-mentioned water-based UV silver powder coating is the same as that of Example 1, and the water-based UV silver powder coating...

Embodiment 3

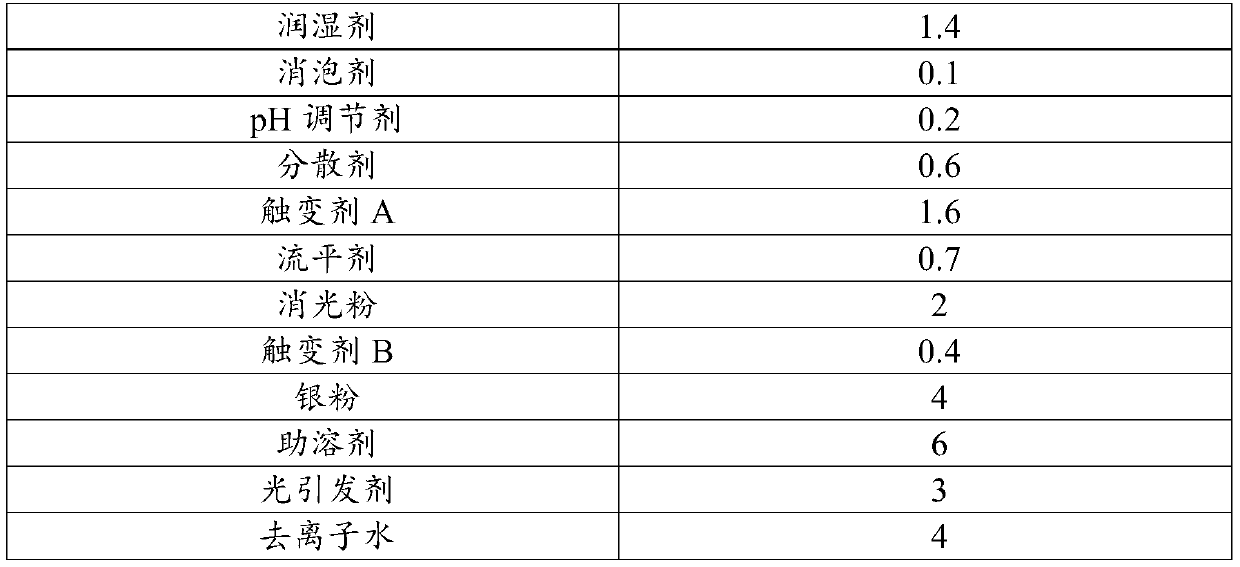

[0079] The water-based UV silver powder coatings in Example 3 are listed in Table 3 in parts by mass.

[0080] Table 3 Composition of waterborne UV silver powder coating components

[0081]

[0082]

[0083] Compared with Example 1, the difference in components of this example is that thixotropic agent A is 1.6 parts, thixotropic agent B is 0.4 parts, and the mass ratio of thixotropic agent A to thixotropic agent B is 4:1.

[0084] The preparation method of the above-mentioned water-based UV silver powder coating is the same as that of Example 1, and the water-based UV silver powder coating 3 is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com