UV orange-peel agent and orange-peel paint

An orange pattern agent and orange pattern technology, applied in the field of coatings, can solve the problems of difficult construction, poor pattern concave and convex feeling, etc., and achieve the effect of solving difficult construction, good effect and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

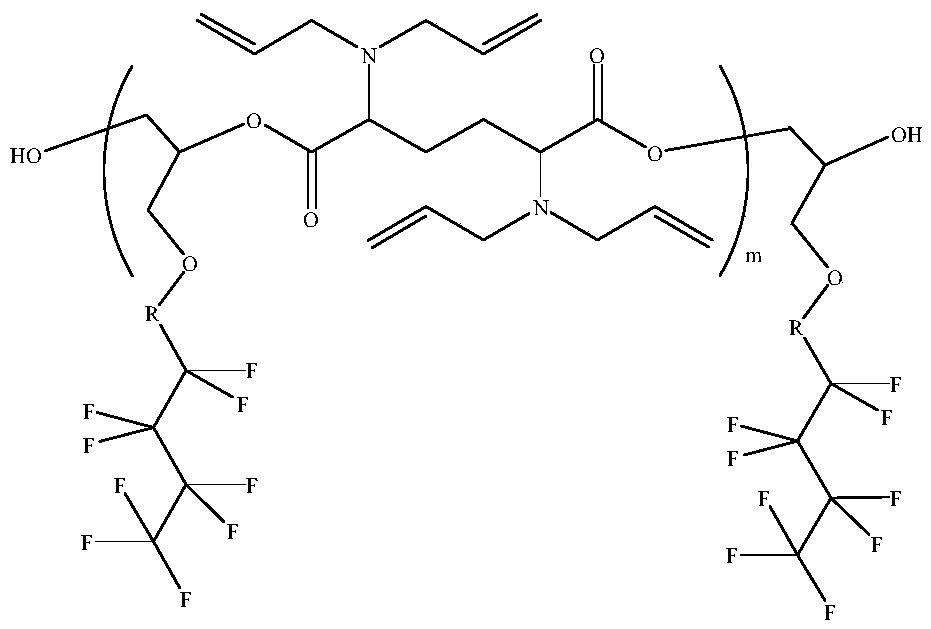

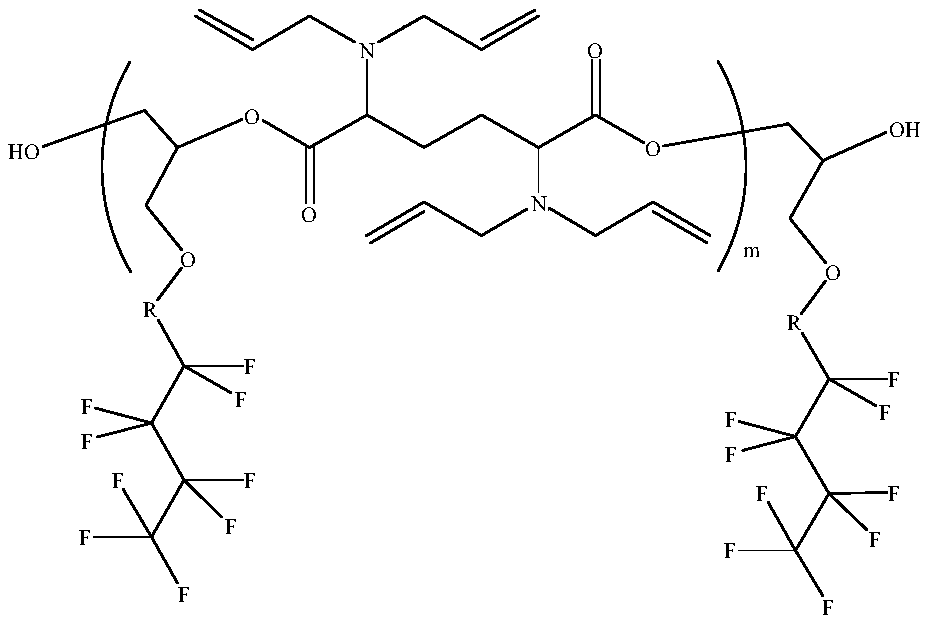

Image

Examples

Embodiment 1

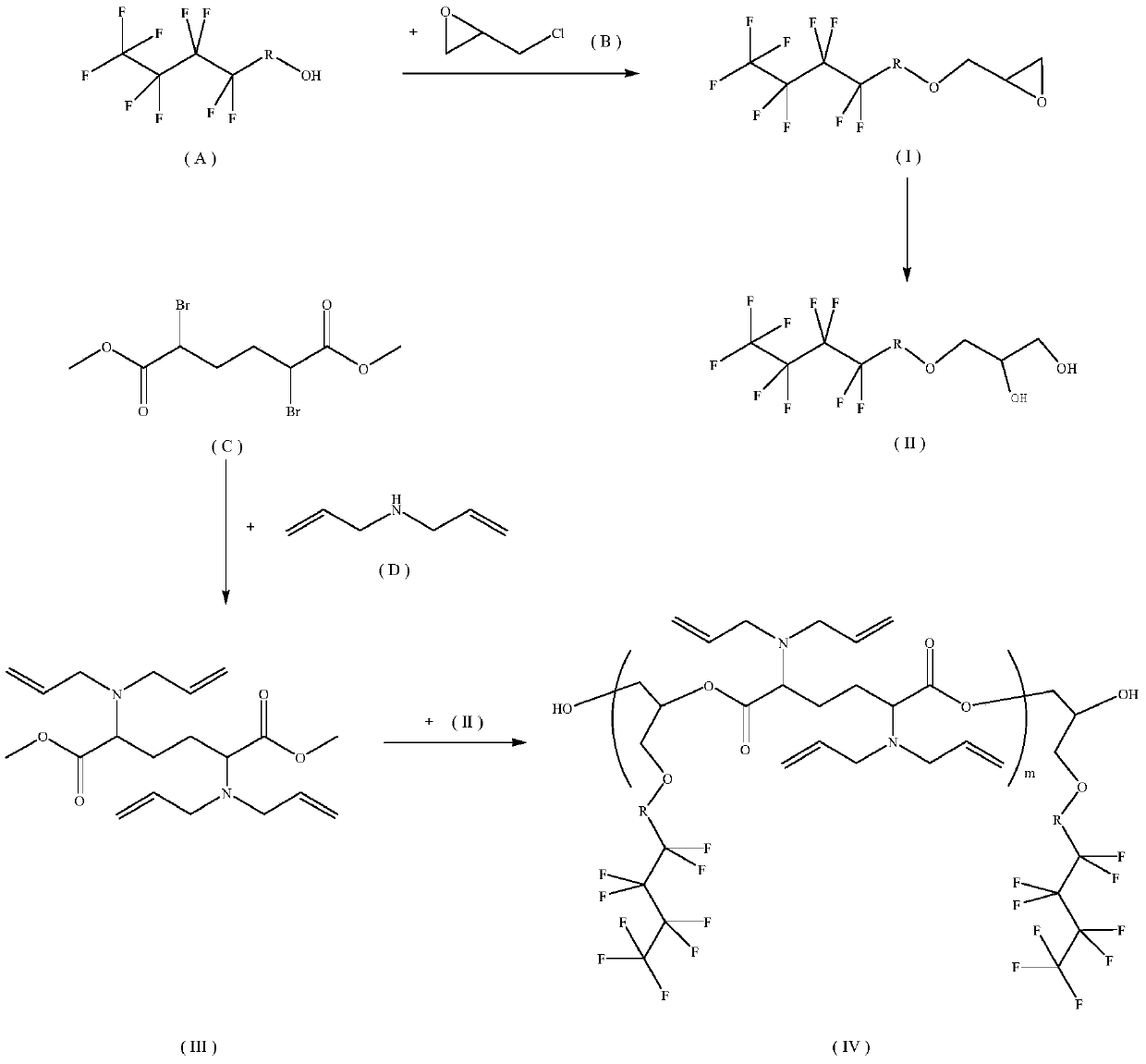

[0046] Orange grain agent preparation steps are as follows:

[0047] (1) 1mol of fluorine-containing monohydric alcohol (A) is added to the mixture containing 3wt% BF 3 In 1.1mol epichlorohydrin (B) in diethyl ether, heat to 45°C, react for 6h; stand still, and distill under reduced pressure at 40°C to obtain a ring-opening intermediate product; add 1.2mol sodium hydroxide to 1mol ring-opening intermediate product , stirred at 45°C for 4h, washed 3 times with deionized water, and obtained the ring-forming intermediate I (IR: 3509cm -1 : -OH disappears; 1253cm -1 :-C-F exists; 911cm -1 : presence of epoxy group; 1599cm -1 : C-O-C exists);

[0048] The BF 3 The dosage is 3wt% of the weight of A.

[0049] (2) Add 5 parts by weight of 2% aqueous sodium hydroxide solution to 1 part by weight of III, and stir at 40°C for 8 hours to obtain intermediate product II (IR: 1253cm -1 :-C-F exists; 1599cm -1 : C-O-C exists; 911cm -1 : Epoxy disappears; 3523cm -1 :-OH exists).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com