Separation device for metal particles in rice flour

A technology of metal particles and separation device, which is applied in the fields of magnetic separation, solid separation, grain processing, etc., can solve the problems of difficult removal, uneven pulverization, poor water absorption and preparation of nutritional rice flour, and achieves convenient and fast use. Screening efficiency, good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

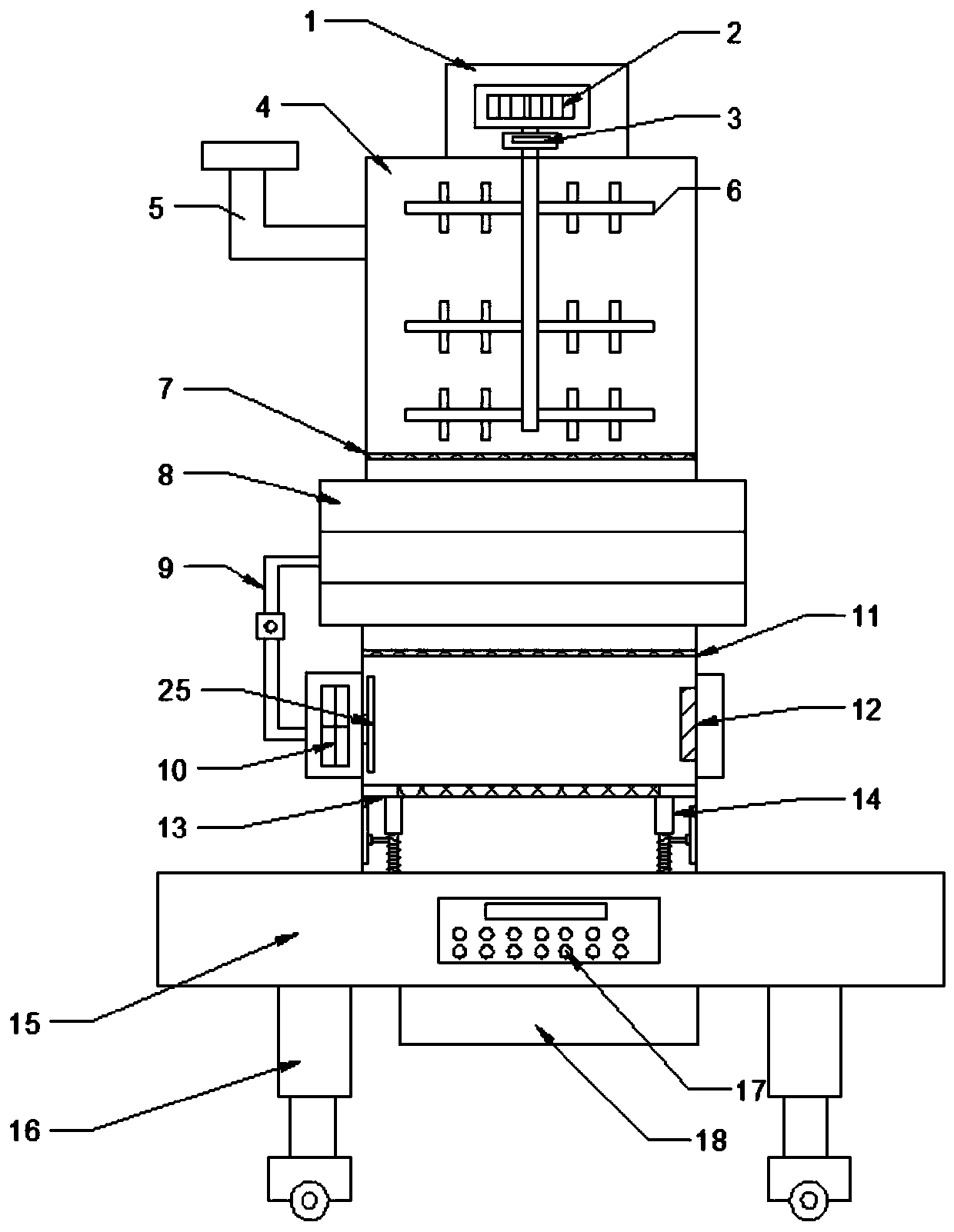

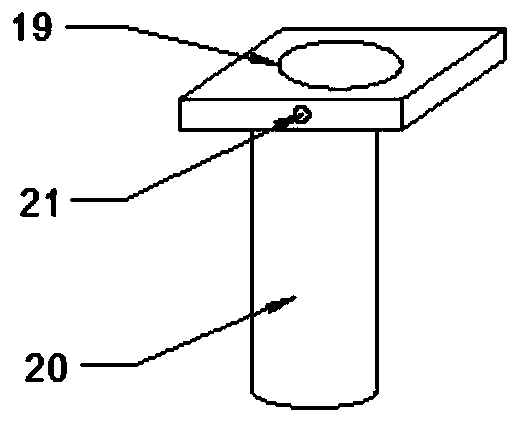

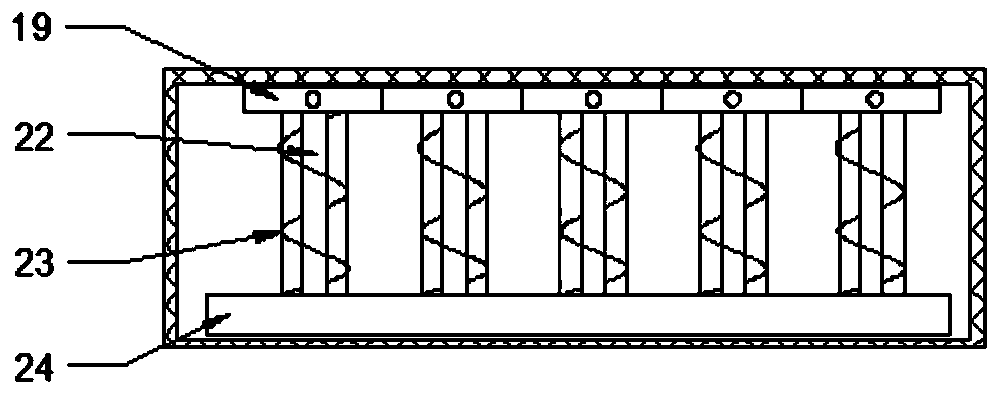

[0020] See Figure 1~3 In the embodiment of the present invention, a separation device for metal particles in rice noodles includes a crushing box 4; a driving box 1 is installed on the top of the crushing box 4; and a feeding pipe is installed on one side of the crushing box 4 6; The inside of the crushing box 4 is provided with a crusher 5 corresponding to the driving box 1; the bottom of the crushing box 4 is installed with a No. 1 screening box 8; the No. 1 screening box 8 is provided with a No. 1 screening mechanism; the No. 1 The bottom end of the screening box 8 is equipped with a No. 2 screening box; the inside of the No. 2 screening box is provided with a No. 2 screening mechanism; the No. 2 screening box is installed on the top of the base 15; the base 15 is provided with a control panel 17 ; The bottom end of the base 15 corresponds to the second screening box with a storage box 18.

[0021] Further, a drive motor 2 is installed inside the drive box 1; the drive motor...

Embodiment 2

[0027] See figure 1 A moving mechanism 16 is installed at the bottom end of the base 15; the moving mechanism 16 includes a hydraulic lifting rod; there are at least four hydraulic lifting rods; a lifting box is installed at the bottom of the hydraulic lifting rod; There is a lifting mechanism inside the lifting box; the bottom end of the lifting mechanism is correspondingly connected with a universal wheel; through the setting of the lifting mechanism, the universal wheel can be stored inside the lifting box; the height of the device can be adjusted by the setting of a hydraulic lifting rod , It is more convenient and faster to use.

[0028] The working principle of the present invention is: through the setting of the drive motor 2, the reversing mechanism 3 and the pulverizer 5, the material is pulverized, and then the rice noodles with a certain degree of pulverization are screened through the No. 1 screen 7; through the shunt pipe and the air pipe 9. The filter 21 is set up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com