Contact sliding telescopic fan blade

A fan blade and fan blade technology is applied in the fields of helicopter wind rotor blades and large industrial ceiling fan blades. Clean fan blades, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

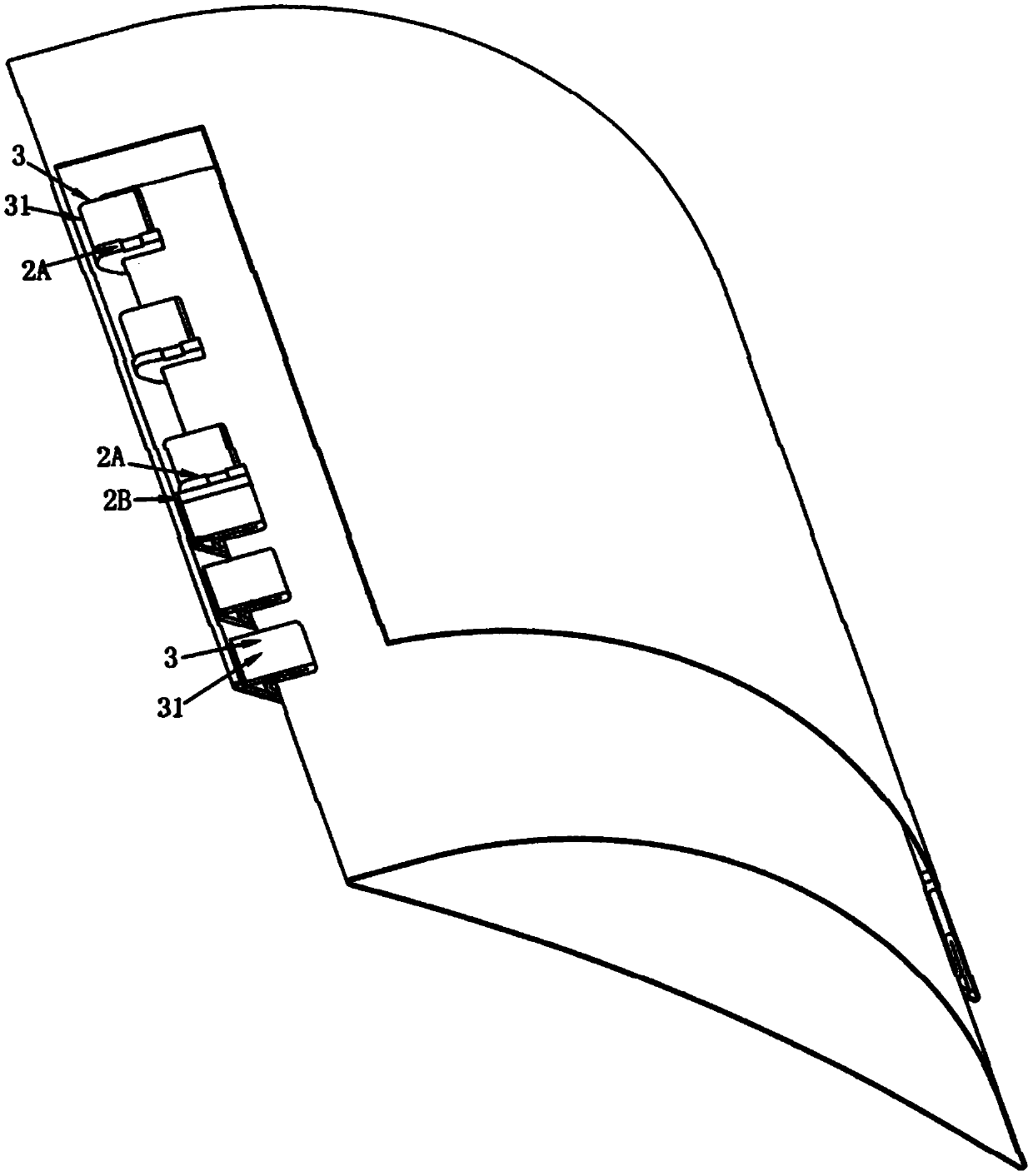

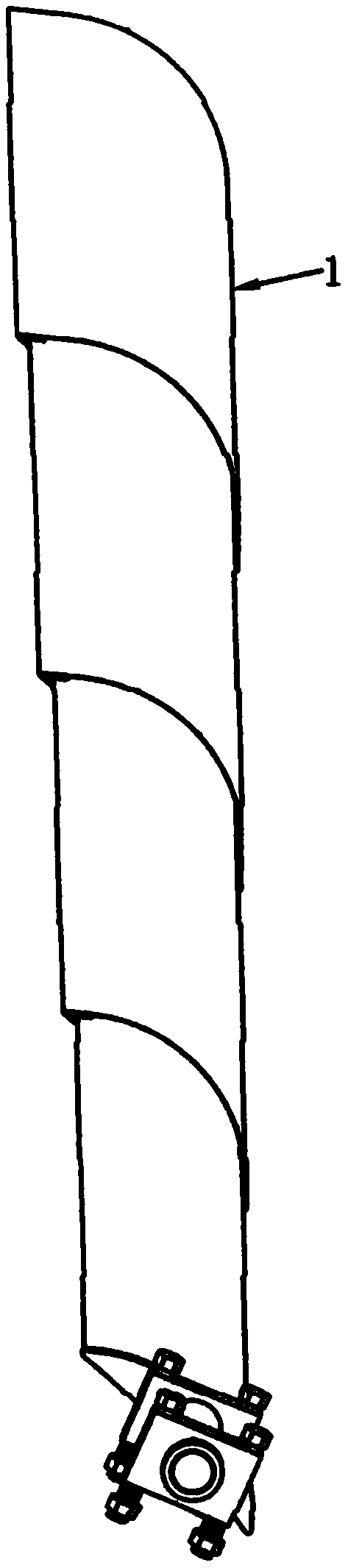

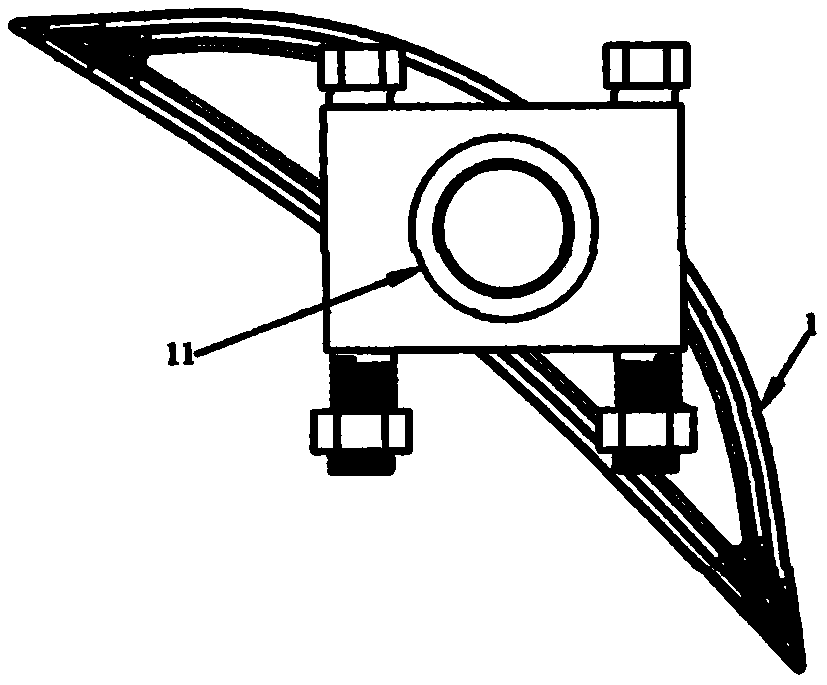

[0111] Embodiment one: if figure 1 , 2 As shown in , 3, 420 grade stainless steel meniscus curved surface straight tube fan blade, plastic slider and V-shaped sliding contact sliding telescopic fan blade, including: multiple contact sliders 2 and at least two-level limit cards Hasp 3; characterized in that: the plurality of contact sliders 2 are set on the surface and slideway of the telescopic fan blade 1 to touch and slide the telescopic fan blade 1; the limit locking hasp 3 is fixedly connected to The inside of one end of the slideway on both sides of each telescopic fan blade and the outside of the other end of the two sides of the slideway are arranged in a linear array at least two, forming at least one level of buckle and two levels of anti-off; the contact slider 2 is fixedly connected Slidingly touch the fan blade on the limit locking buckle 3;

[0112] The telescopic fan blade 1 is composed of multi-section large and small casing coaxially sliding and telescopic so...

Embodiment 2

[0123] Embodiment two: if figure 1 , 2 , 3, 65Mn grade carbon spring steel meniscus curved surface straight tube fan blade, graphite slider and V-shaped slideway contact sliding telescopic fan blade, the structure of the second embodiment is similar to the first embodiment, the difference is:

[0124] The multi-section casing fan blade is formed by bending and forming metal carbon spring steel 65Mn grade sheet metal;

[0125] The contact slider is pure carbon graphite M191T made of graphite; the graphite block made of graphite is fixedly connected to the limit locking buckle 3 to slide the fan blade;

[0126] Lubricating powder is adhered to the surface of the multi-section casing fan blade and the contact slider 2 to reduce friction and noise; the lubricating powder is graphite powder; the graphite powder is ground on the surface of each casing fan blade and the fan blade original groove 37 of the contact slider 2 touches and slides the fan blade;

[0127] The graphite pow...

Embodiment 3

[0129] Embodiment three: as Figure 5 , 9 As shown in . Locking hasp 3; characterized in that: the plurality of contact sliders 2 are set on the surface and slideway of the telescopic fan blade 1 to touch and slide the telescopic fan blade 1; the limit locking hasp 3 is fixedly connected There are at least two linear arrays on the inside of one end of the slideway on both sides of each telescopic fan blade and the outside of the other end of the two sides of the slideway, forming at least one level of buckle and two levels of anti-off; the contact slider 2 is fixed Connected to the limit locking buckle 3 to slide the fan blade;

[0130] The telescopic fan blade 1 is composed of multi-section large and small casing coaxially sliding and telescopic sockets to form a casing fan blade, and a limit locking buckle 3 is respectively set on the inner side of one end of the casing and the outer side of the other end of the casing. ;

[0131] Such as Figure 40 , 43 , as shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com