Gravity type anti-overturning device suitable for single-pier bridge

A gravity-type, anti-overturning technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of device and bridge damage, difficult construction, long construction period, etc., and achieve the effect of preventing overturning, convenient construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention is further described:

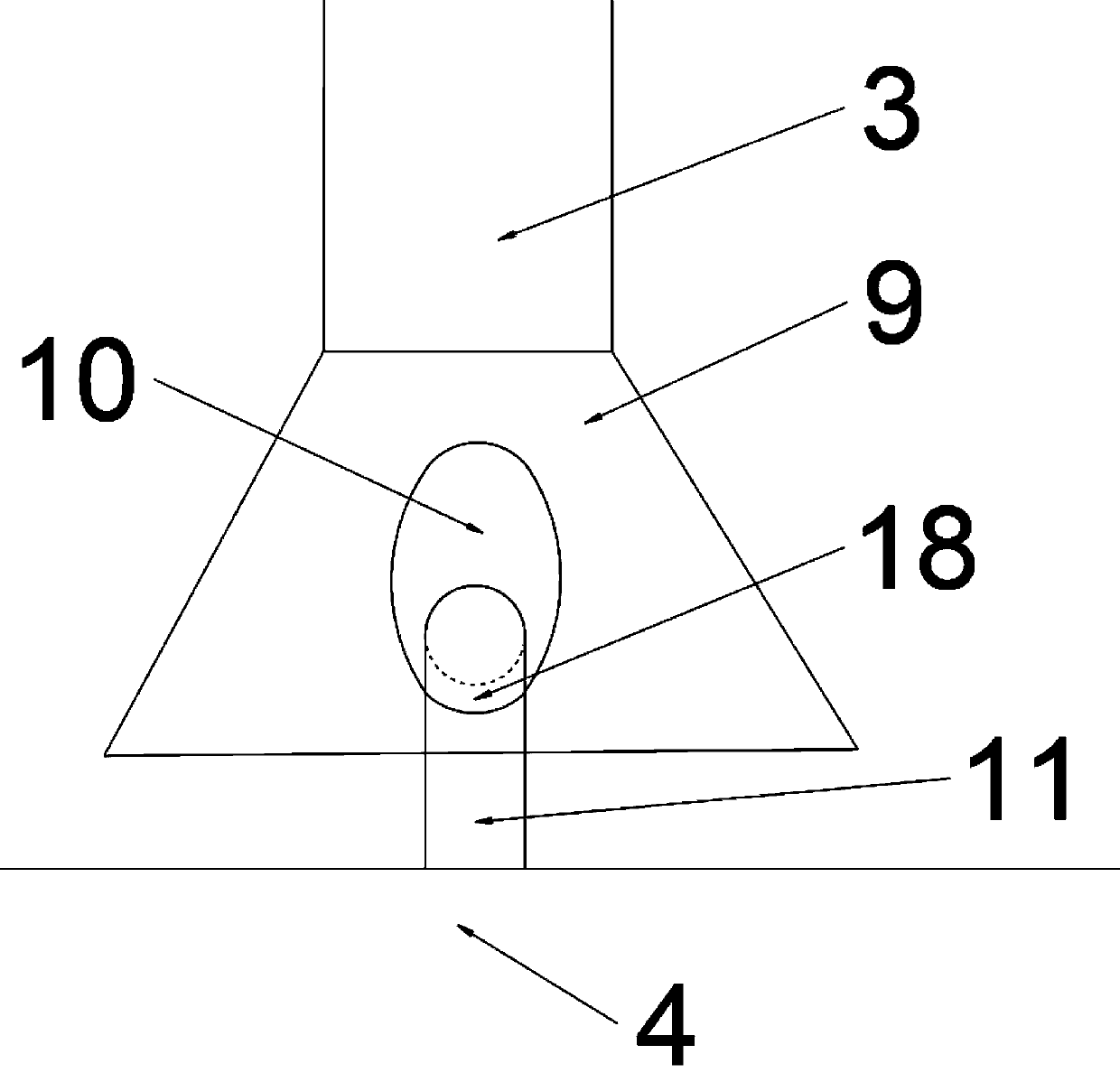

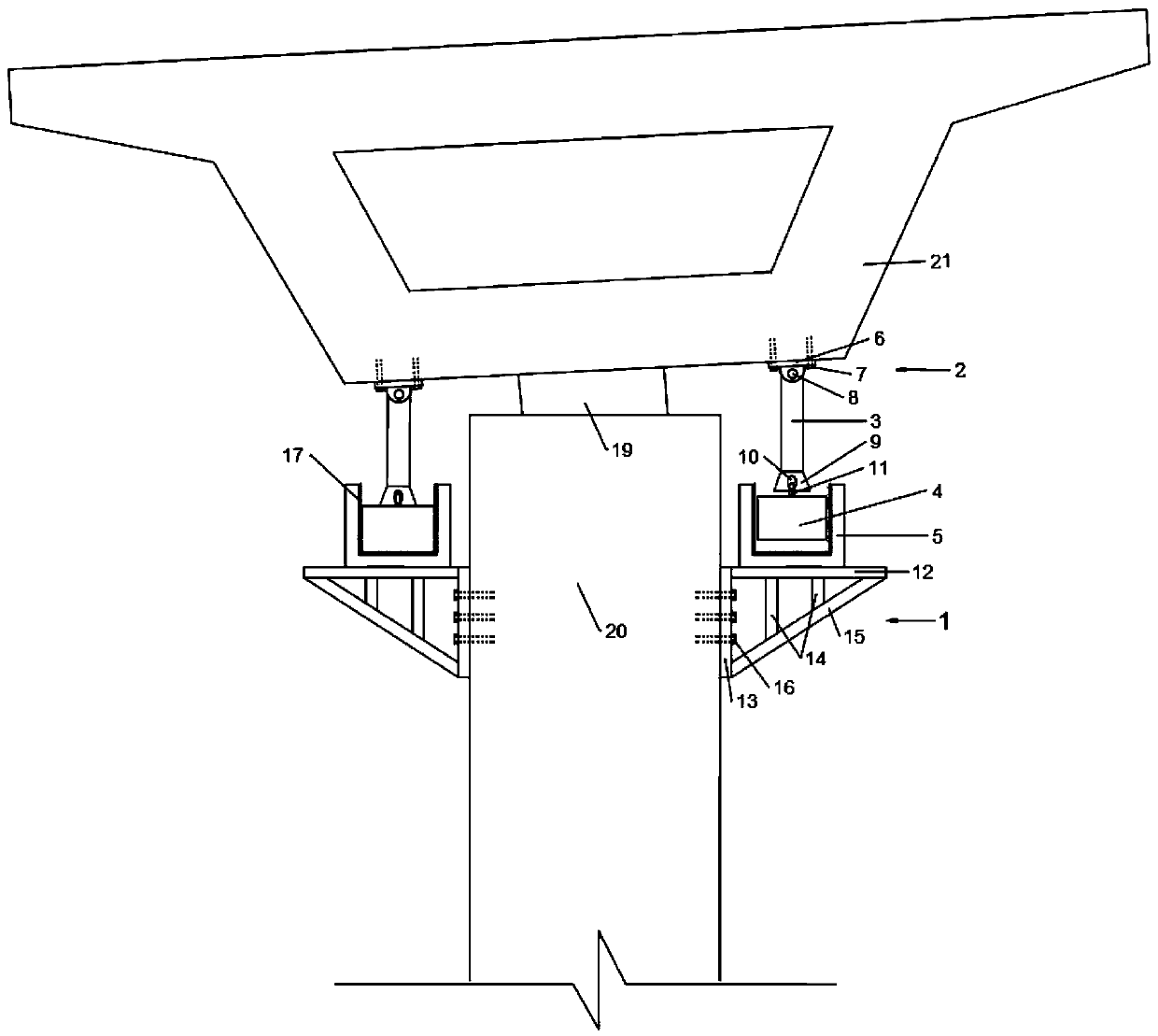

[0027] see Figure 1-5 ,

[0028] The invention discloses a gravity type anti-overturning device suitable for a single column pier bridge, which comprises a steel corbel 1, a fixed hinge support 2, a tie rod 3, a lead post 4 and a square stopper 5; the steel corbel 1 is fixed On the side of the pier 20, the square block 5 is a hollow square structure with an open top, and its bottom is fixed on the top of the steel corbel 1; the lead column 4 is placed inside the cavity of the square block 5 One end of the pull rod 3 is connected to the top of the lead column 4, and the other end is hinged to the fixed hinge support 2; the fixed hinge support 2 is fixed on both sides of the bottom of the beam body 21.

[0029] Described steel corbel 1 comprises steel corbel top plate 12, steel corbel inner plate 13, steel corbel bottom plate 15 and steel corbel web 14, and described steel corbel inner plate 13 is provided with severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com