A kind of stainless steel plate for lamination and its manufacturing method

A stainless steel plate and stainless steel technology, applied in the field of stainless steel products and its preparation, can solve the problems of high price, poor plate shape, high alloy cost, etc., and achieve the effects of easy plate shape control, good rust resistance, and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0097] After the smelted molten steel is cast into a stainless steel slab, it is fully ground at a certain temperature to remove the surface defects of the stainless steel slab. The temperature after the grinding is greater than 200°C. The chemical composition of the stainless steel slabs is shown in Table 1.

[0098] The chemical composition of table 1 embodiment 1-5 stainless steel slab

[0099] Example C Si mn S P Cr Ni Mo N V PREN Mrs. 1 0.22 0.7 0.6 0.005 0.03 12 0.11 0.95 0.09 0.11 16.9 233.1 2 0.16 0.9 0.3 0.002 0.023 13.1 0.3 0.8 0.06 0.08 16.9 265.4 3 0.31 0.3 0.8 0.001 0.028 13.6 0.13 0.5 0.05 0.04 16.2 189.2 4 0.35 0.4 0.35 0.003 0.025 13.9 0.15 0.55 0.05 0.12 16.7 181.3 5 0.28 0.6 0.4 0.001 0.027 13.5 0.21 0.75 0.12 0.09 18.3 182.1

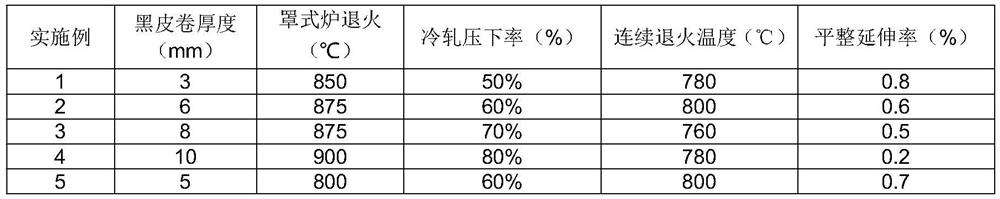

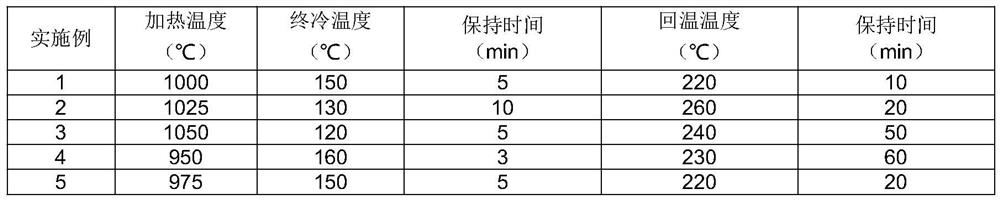

[0100] The ground stainless steel slab is heated in a heating furnace, hot rolled, annealed in a bell furnace, pickled, cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com