Method for recovering gold from gold-loaded carbon in thiosulfate system

A technology of thiosulfate and recovery method, which is applied in the field of recovery of gold on gold-loaded carbon in thiosulfate system, to achieve the effects of easy re-modification, good desorption effect, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

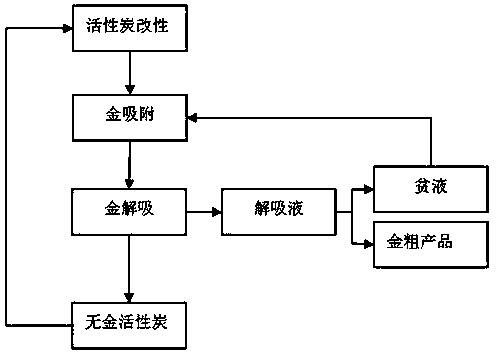

Method used

Image

Examples

Embodiment 1

[0021] (1) Take 2.0g of the first granular activated carbon with a gold loading capacity of 2.0kg / t, wash it with deionized water, remove powder dust, filter, and heat in an oven at 100°C for 48h (the first granular Activated carbon is: first modified by 2-mercaptobenzothiazole, and then obtained from Au(S 2 o 3 ) 2 3- activated carbon after adsorption of gold in the solution).

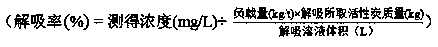

[0022] (2) According to the liquid-solid ratio (mL:g) of 100, put 2.0g of the gold-loaded carbon dried in step (1) into 200ml of 0.3mol / L sodium thiosulfate solution, stir and desorb for 12h The concentration of gold in the solution was measured by atomic absorption, the activated carbon was taken out, and dried; the calculated desorption rate was 61%.

[0023]

[0024] (3) Re-modify the desorbed activated carbon, analyze and calculate the gold adsorption capacity of the re-modified activated carbon, the specific method is:

[0025] Take 2g of desorbed activated carbon, wash with deionized w...

Embodiment 2

[0030] (1) Take 2.0g of the first granular activated carbon with a gold loading capacity of 2.0kg / t, wash with deionized water, remove powder dust, filter, and bake at 250°C for 24h (the first granular activated carbon is: first Modified by 1-methyl-5-mercaptotetrazolium, and then obtained from Au(S 2 o 3 ) 2 3- activated carbon after adsorption of gold in the solution).

[0031] (2) According to the ratio of liquid to solid (mL:g) of 5, put 2.0g of the gold-loaded carbon dried in step (1) into 0.05mol / L sodium thiosulfate solution for 1h and then use atomic absorption to determine Gold concentration in the solution, remove the activated carbon, and dry it. The calculated desorption rate is 100% (the calculation method is the same as in Example 1).

[0032] (3) Re-modify the desorbed activated carbon, analyze and calculate the gold adsorption capacity of the re-modified activated carbon, the specific method is:

[0033] Take 5.0 g of desorbed granular activated carbon,...

Embodiment 3

[0038] (1) Take 2.0g of the third granular activated carbon with a gold loading capacity of 2.0kg / t, wash with deionized water, remove powder dust, filter, and heat at 400°C for 1h (the third granular activated carbon is: First modified by 2-mercaptobenzoxazole, and then obtained from Au(S 2 o 3 ) 2 3- activated carbon after adsorption of gold in the solution).

[0039] (2) According to the liquid-solid ratio (mL:g) of 40, put 2.0g of gold-loaded carbon dried in step (1) into 0.25mol / L sodium thiosulfate solution for desorption for 24h, take out the activated carbon and use The concentration of gold in the solution was determined by atomic absorption and dried. The calculated desorption rate is 74% (the calculation method is the same as in Example 1).

[0040] (3) Re-modify the desorbed activated carbon, analyze and calculate the gold adsorption capacity of the re-modified activated carbon, the specific method is:

[0041] Take 2.0 g of desorbed activated carbon, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com