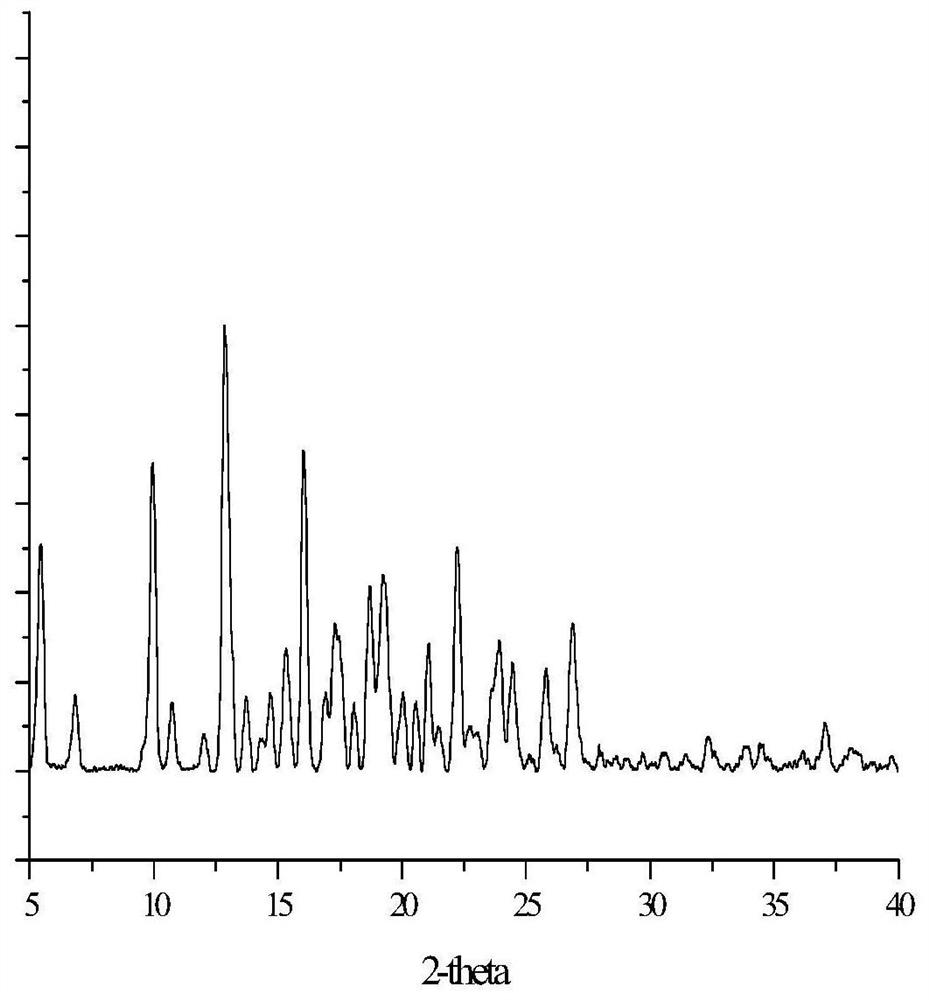

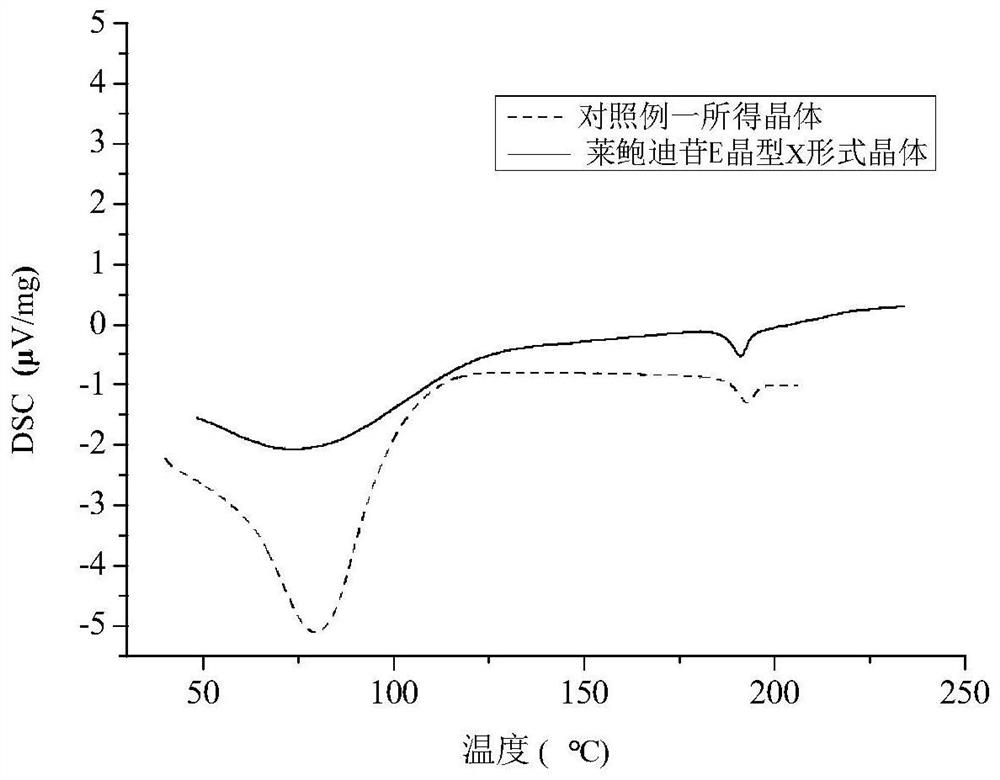

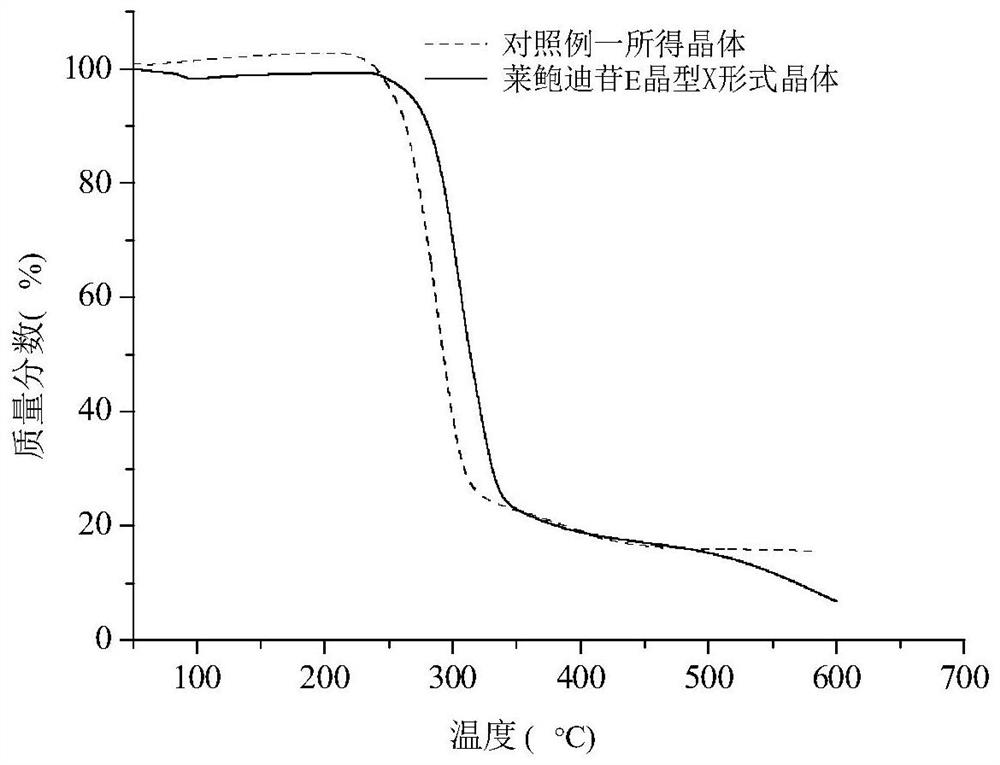

A crystal form x of rebaudioside e, its preparation method and use

A crystal form and crystal technology, which is applied in the preparation of sugar derivatives, organic chemical methods, chemical instruments and methods, etc., can solve the problems of rare reports on the crystal structure and crystallization method of rebaudioside E, difficulty in obtaining crystals in large quantities, and low solubility and other problems, to achieve the effect of high crystallinity, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 1 g of rubusoside with a purity of 95% in 100 mL of 90% aqueous ethanol and heat to 70°C. 65 g of rebaudioside E with a purity of 95% was slowly added to the above solution, and stirred at 70° C. to obtain a suspension solution. Then filter while hot to obtain supernatant and filter residue respectively. The supernatant was stirred at a speed of 20 rpm and cooled to 4°C at a speed of 2°C / min, and a white solid was precipitated. Collect the separated white solid by suction filtration, wash the crystal with 90% ethanol aqueous solution at 10°C, and then dry the crystal in vacuum at 30°C to obtain 30g of rebaudioside E crystal with crystal form X. The polarized light micrograph is as follows: Figure 4 as shown in a.

Embodiment 2

[0039] Dissolve 2 g of rubusoside with a purity of 95% in 100 mL of 90% aqueous methanol and heat to 58°C. 55 g of rebaudioside E with a purity of 90% was slowly added to the above solution, and a suspension solution was obtained after stirring. Then filter while hot to obtain supernatant and filter residue respectively. The supernatant was stirred at a speed of 50 rpm and cooled to 10° C. at a speed of 3° C. / min, and a white solid was precipitated. The precipitated white solid was collected by filtration, the crystal was washed with 90% methanol aqueous solution at 10°C, and then evaporated and dried at 50°C to obtain 35 g of rebaudioside E crystal with crystal form X.

Embodiment 3

[0045] 3 g of rubusoside with a purity of 75% was dissolved in 100 mL of 95% aqueous ethanol and heated to 70°C. 80 g of rebaudioside E with a purity of 80% was slowly added to the above solution, and a suspension solution was obtained after stirring. Then filter while hot to obtain supernatant and filter residue respectively. The supernatant was stirred at a speed of 40 rpm and cooled to 0° C. at a speed of 1° C. / min, and a white solid was precipitated. Collect the precipitated white solid by filtration, wash the white solid with 95% ethanol aqueous solution at 25°C, and then vacuum-dry the crystal at 30°C to obtain rebaudioside E crystal with crystal form X.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com