Optical glass element with light absorption layer and preparation method of optical glass element

A technology of optical glass and light-absorbing layer, applied in optical components, glass manufacturing equipment, optics, etc., can solve problems such as high-temperature reduction process cannot meet, prepare light-absorbing layer, etc., reduce optical crosstalk, prevent interface reflection, reduce equipment the effect of the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

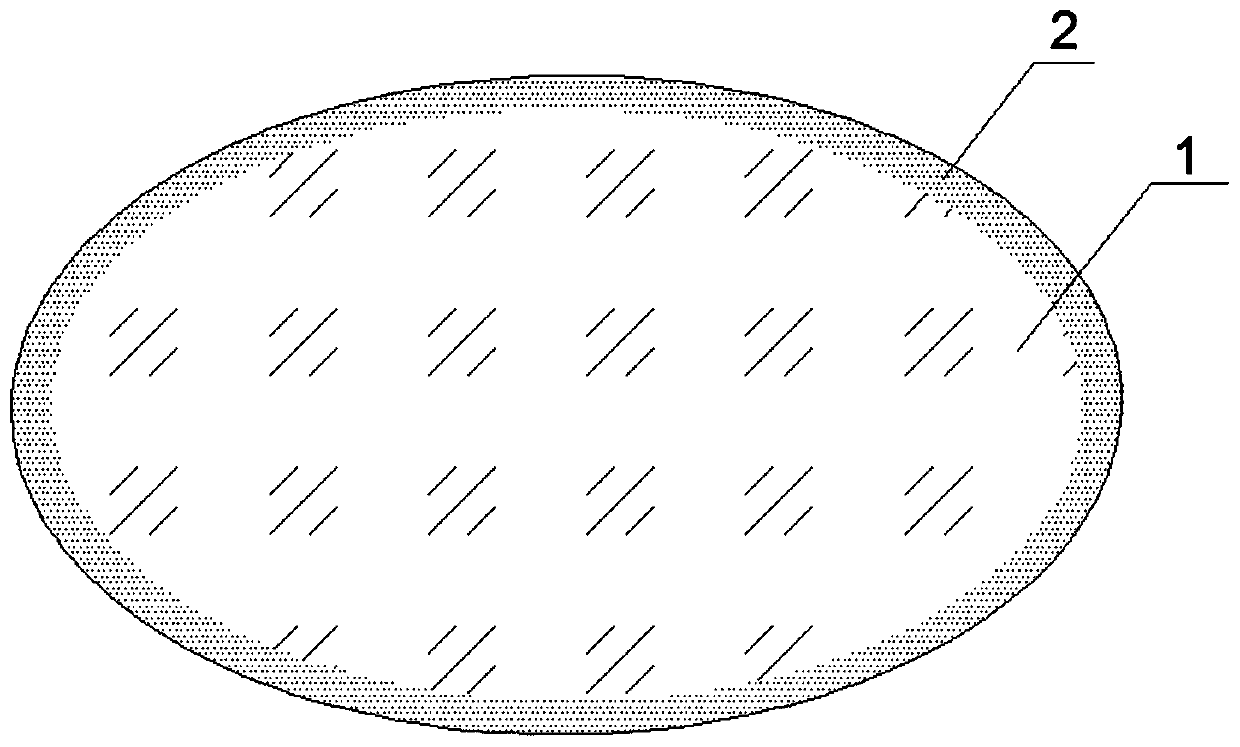

[0034] Such as figure 1 As shown, one embodiment of the present invention proposes a method for preparing an optical glass element with a light-absorbing layer, which specifically includes the following steps:

[0035] Step S1. Perform surface pretreatment on the optical glass to form nano-scale or micron-scale gas diffusion channels on the surface of the optical glass; this step does not specifically limit the method of surface pretreatment, in principle, as long as the surface of the optical glass can be formed into nano-scale or micron-scale gas diffusion channels can be selected, and the surface pretreatment includes but not limited to at least one of sandblasting, acid etching, ion exchange and quenching. When performing surface pretreatment on optical glass, one of the methods can be used, or multiple methods can be used in combination.

[0036] The sand blasting refers to hitting the glass surface with sand particles ejected at high speed from a spray gun, so that the ...

Embodiment 1

[0060] A method for preparing an optical glass element with a light-absorbing layer, specifically comprising the following steps:

[0061] (1) the K9 glass listed in Table 1 is processed to the blank size;

[0062] (2) Sandblasting the surface of K9 glass: choose 1000 mesh Al 2 o 3 Particles, sandblasting the glass surface for 60s under the pressure of 0.6MPa;

[0063] (3) Put the sandblasted K9 glass into the reduction furnace for high-temperature hydrogen reduction, the reduction temperature is 610°C, the hydrogen pressure is 0.2MPa, and the reduction time is 5000min;

[0064] (4) Process the reduced blank to the finished product size.

[0065] After testing, the light absorption efficiency of the light absorption layer is about 99.8%.

Embodiment 2

[0067] A method for preparing an optical glass element with a light-absorbing layer, specifically comprising the following steps:

[0068] (1) the K9 glass listed in Table 1 is processed to the blank size;

[0069] (2) Acid etching treatment for K9 glass: prepare 0.1mol / L nitric acid, heat to 60°C, immerse K9 glass in it for acid etching for 1 hour;

[0070] (3) Put the acid-etched K9 glass into a reduction furnace for high-temperature hydrogen reduction. The reduction temperature is 610° C., the hydrogen pressure is 0.2 MPa, and the reduction time is 5000 min.

[0071] (4) Process the reduced blank to the finished product size.

[0072] After testing, the light absorption efficiency of the light absorption layer is about 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com