Manual circulating meal transfer device

A vegetable pot and braking mechanism technology, applied in transportation and packaging, conveyors, household appliances, etc., can solve the problems of unsuitable promotion and application, installation and use costs, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

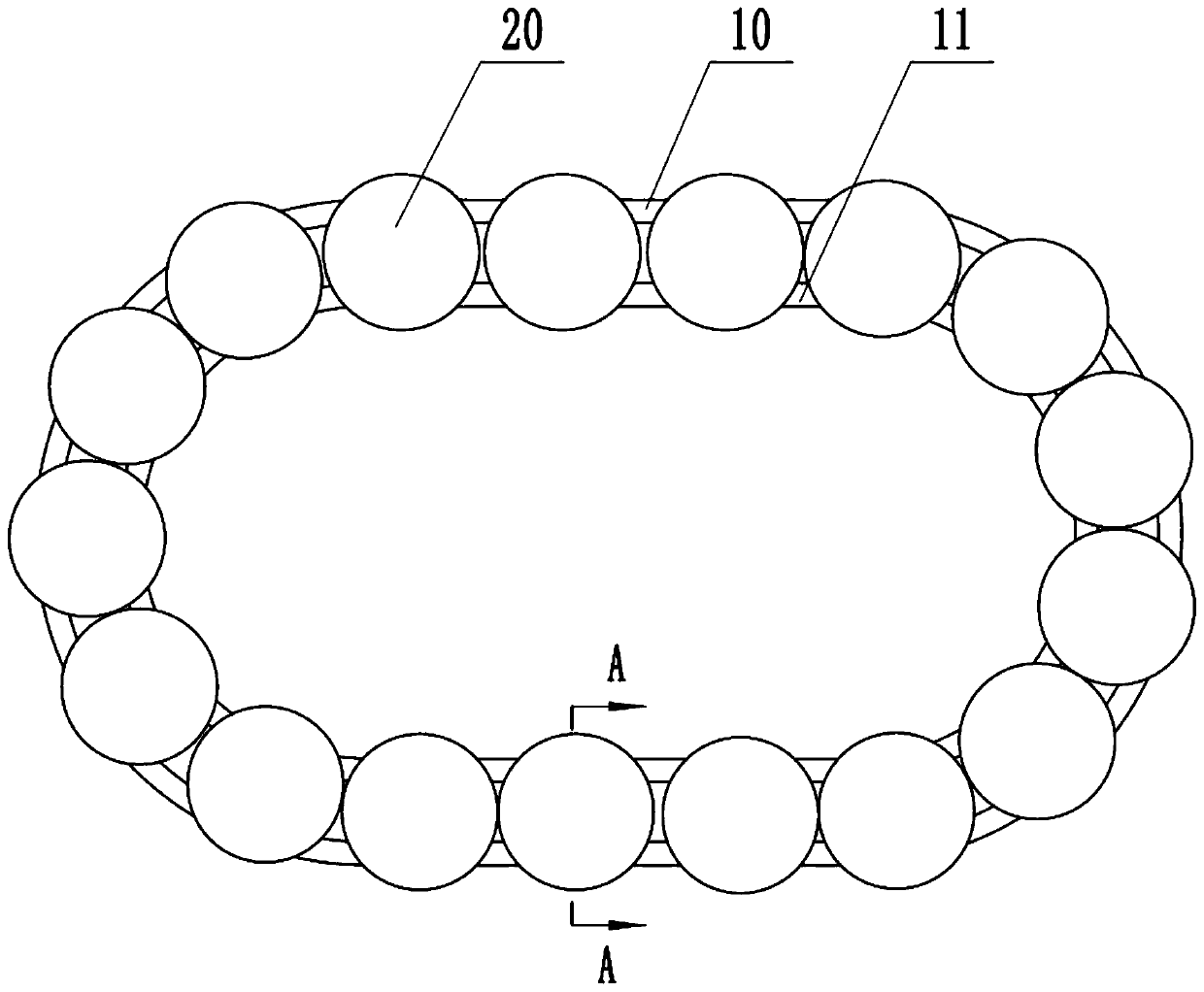

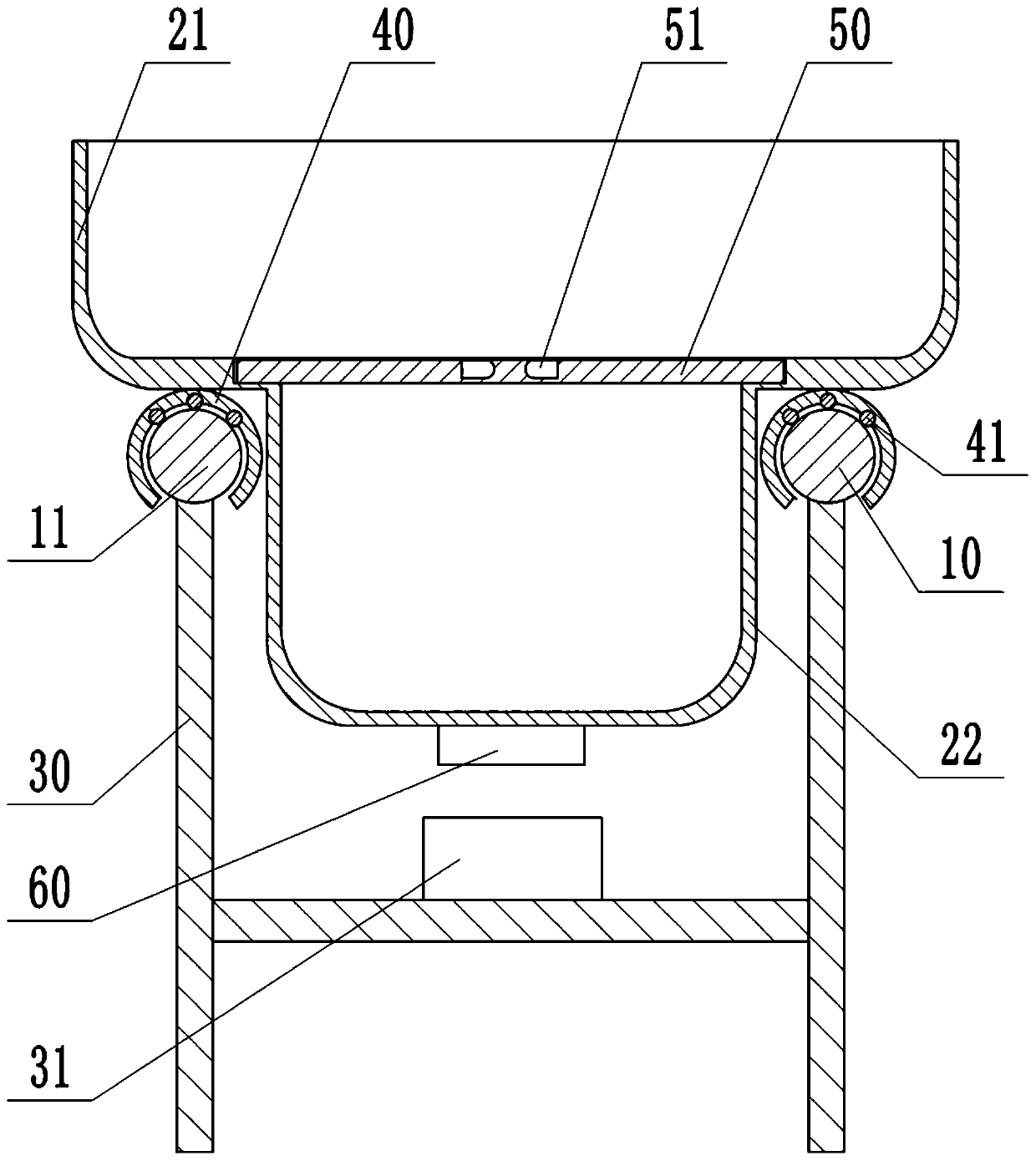

[0025] This embodiment is basically as figure 1 , figure 2 Shown: a kind of manual circulating dish conveying device, comprises braking mechanism, closed conveying track and the frame body 30 that is used to support conveying track, in this embodiment, frame body 30 is fixedly installed on the ground, and conveying track is welded on on the frame body 30. The conveying track includes an inner supporting steel pipe 11 and an outer supporting steel pipe 10, the outer supporting steel pipe 10 surrounds the outer side of the inner supporting steel pipe 11, and the outer supporting steel pipe 10 and the inner supporting steel pipe 11 are concentric. The outer support steel pipe 10 and the inner support steel pipe 11 can be set as circular or elliptical. In this embodiment, the outer support steel tube 10 and the inner support steel tube 11 are set in a shape similar to an ellipse.

[0026] A plurality of sliding sleeves 40 are slidingly connected on the conveying track. Specific...

Embodiment 2

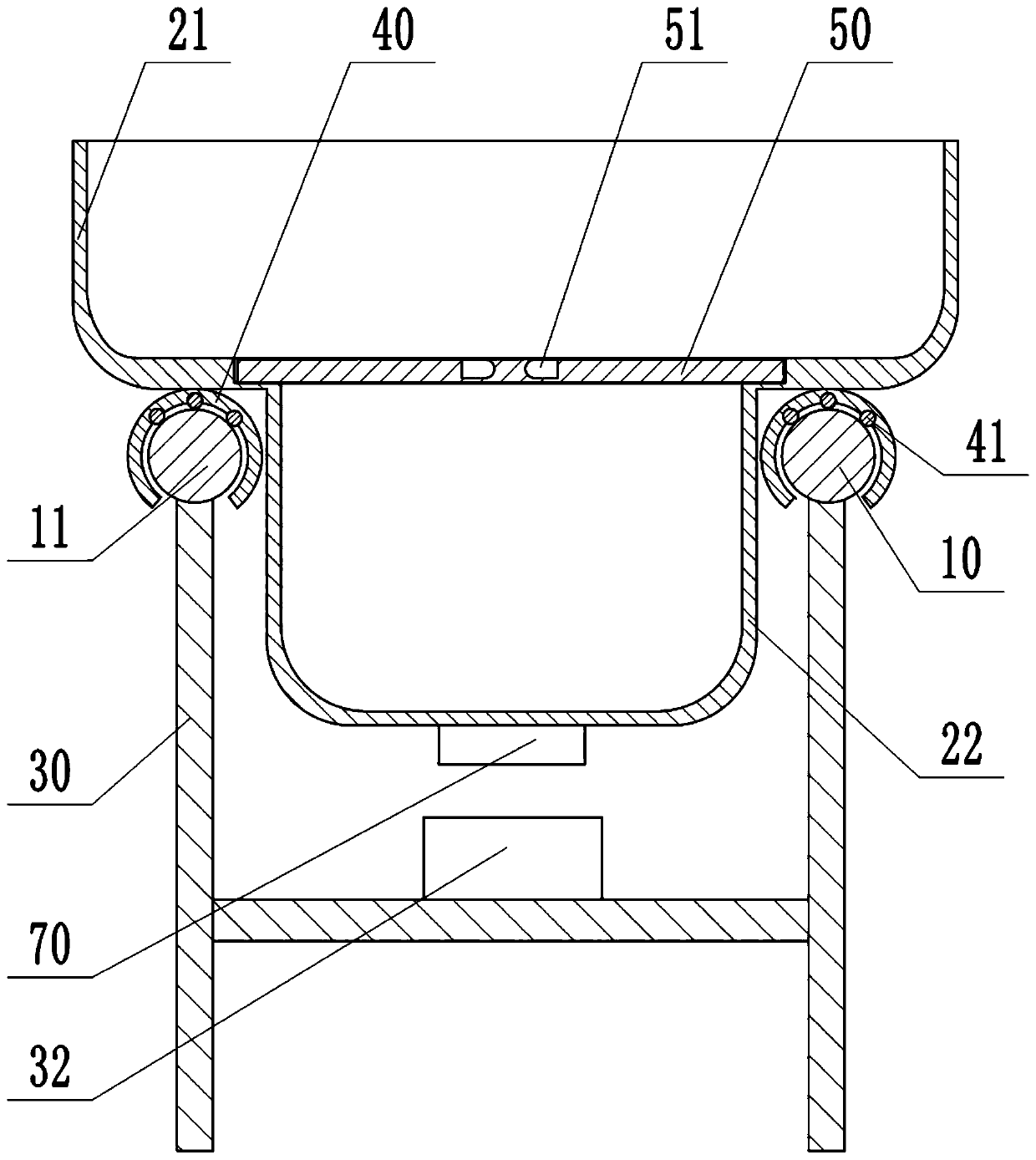

[0032] The difference between this embodiment and Embodiment 1 is that the braking mechanism in this embodiment is different from Embodiment 1, such as image 3 As shown, in this embodiment, the braking mechanism includes a second electromagnet 32, a plurality of magnets 70 and a second switch for controlling the second electromagnet 32 to be powered on and off, and each magnet 70 is installed on each transmission one by one. The bottom of the vegetable pot 20 , the second electromagnet 32 and the second switch are all installed on the frame body 30 . The second electromagnet 32 that uses in the present embodiment is the electromagnet 70 that buys directly on the market, has selected the electromagnet 70 that has enough big magnetic force, when guaranteeing that the second electromagnet 32 is energized, can make the vegetable transfer pot 20 by magnetic force stop moving.

[0033] The internal structure of existing electromagnet 70 is generally made by winding wires o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com