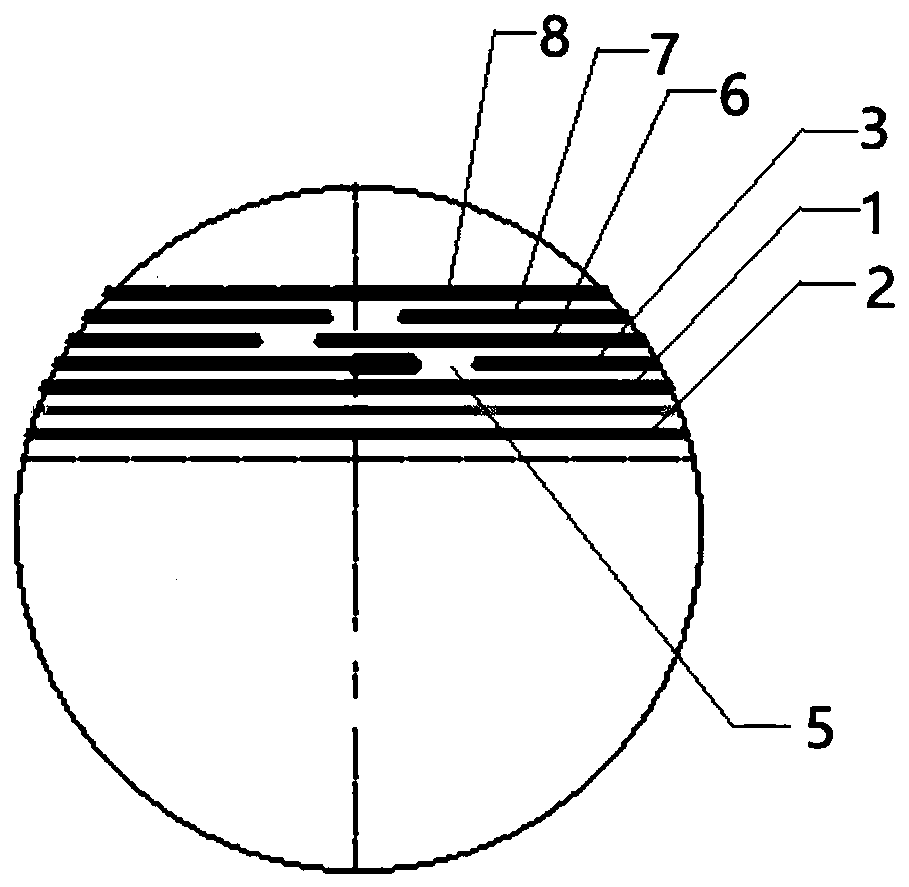

Composite material emission box and preparation method thereof

A composite material and launch box technology, used in launch devices, rocket launch devices, offensive equipment, etc., can solve the problems of limited extension length of nozzles, unguaranteed spraying uniformity of launch boxes, and high initial investment in automatic inner cavity spraying devices. , to meet the wall thickness requirements, the construction is simple, and the effect of ensuring the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

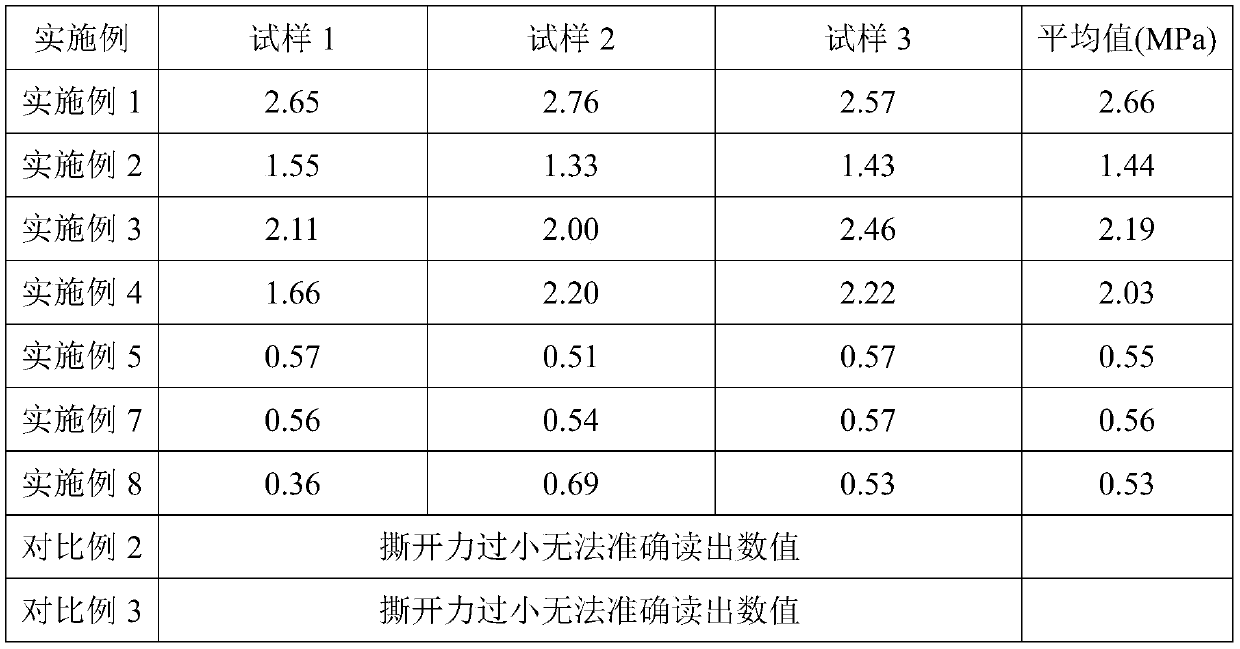

Embodiment 1

[0045] In this embodiment, the material of the heat-proof layer is the room temperature vulcanized silicone rubber ablation-resistant coating BBTC-2516 produced by Beijing Glass Steel Institute Composite Material Co., Ltd.; the resin material of the composite material layer is vinyl resin, purchased from Shangwei (Shanghai ) Fine Chemical Co., Ltd., the product name is swancor-901; reinforcement material Changzhou Hongfa Zongheng customized multi-axial stitch-bonded glass fiber fabric.

[0046] A kind of preparation method of composite launch box described in the present embodiment, comprises the following steps:

[0047] S0. Mold treatment: Paste 0.18mm thick tetrafluoroethylene tape with a certain strength on the surface of the mold, and the seam of the tetrafluoroethylene tape is not perpendicular to the demoulding direction, and avoid the seam of the tape at the corner of the mold. There must be no air bubbles and no wrinkles when pasting, and the seams should be perfectly...

Embodiment 2

[0058] The preparation method of a kind of composite material launching box described in this embodiment, other steps are all the same as embodiment 1, the difference is that in step S2, between vacuum pouring vinyl resin material and spraying heat-proof layer material in step S1 6 hours apart.

Embodiment 3

[0060] The preparation method of a kind of composite material launching box described in this embodiment, other steps are all the same as embodiment 1, the difference is that in step S2, between vacuum pouring vinyl resin material and spraying heat-proof layer material in step S1 22 hours apart.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com