Pillow base body, temperature control pillow and production process of temperature control pillow

A pillow and matrix technology, which is applied to the production process of temperature-controlled pillows and temperature-controlled pillows, and the pillow matrix field, can solve the problems that latex materials are not easy to clean, cannot control the temperature of pillows, and have poor use comfort, so as to promote blood microcirculation, reduce The effect of cervical pressure and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

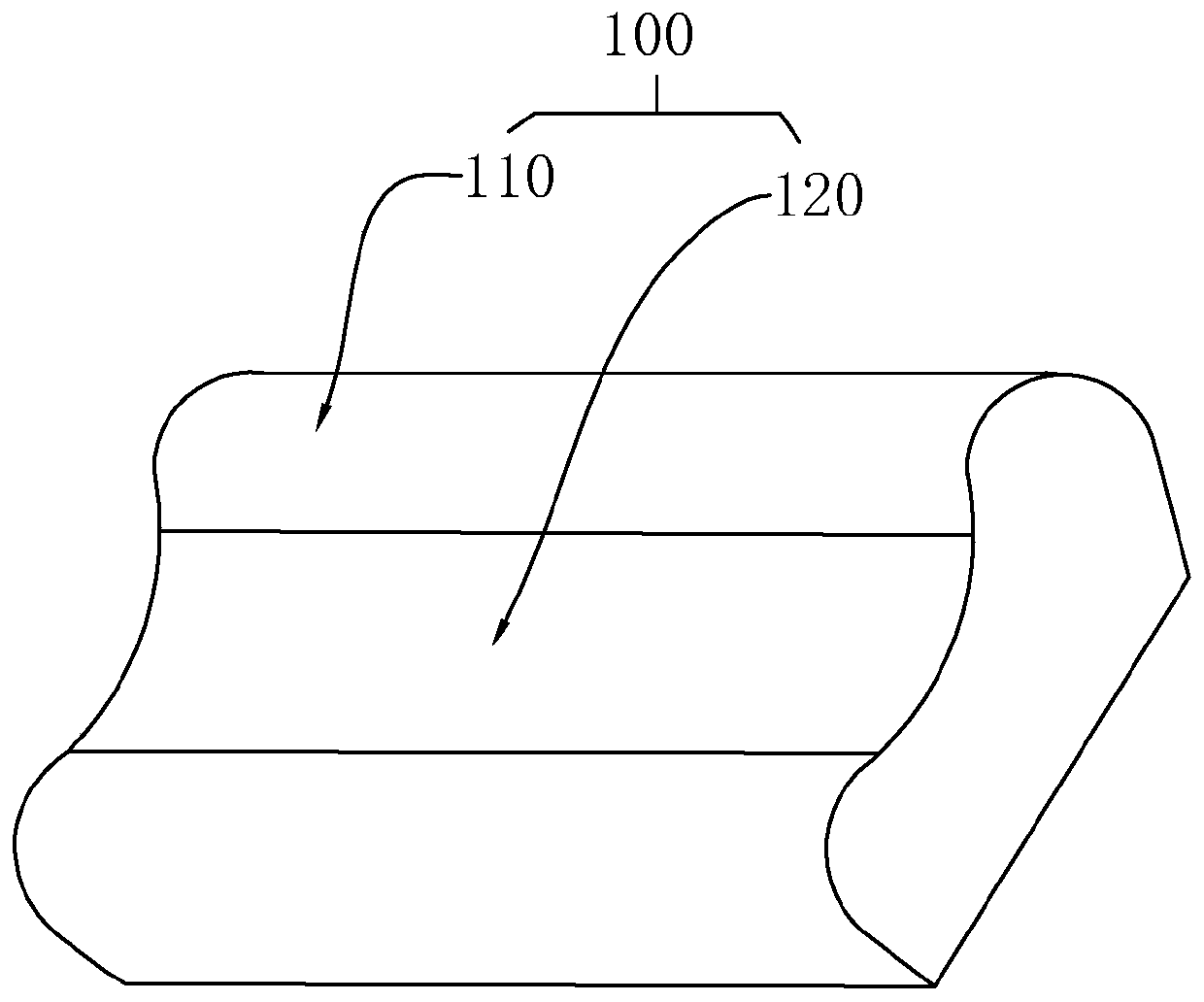

[0051] refer to figure 1 , a pillow base in this embodiment, the base 100 is made of silicone material, including a neck support part 110 and a head support part 120, the neck support part 110 is in the shape of a circular arc protrusion, and the head support part 120 It is arc-shaped and concave. The base body 100 is injection-molded with silicone material, which is easy to clean, has a long service life, and does not change color. It is equipped with a neck support part 110 and a head support part 120, which conforms to the ergonomic principle and can effectively reduce the pressure on the cervical spine. Promotes blood microcirculation, releases body pressure, and helps to fall asleep easily.

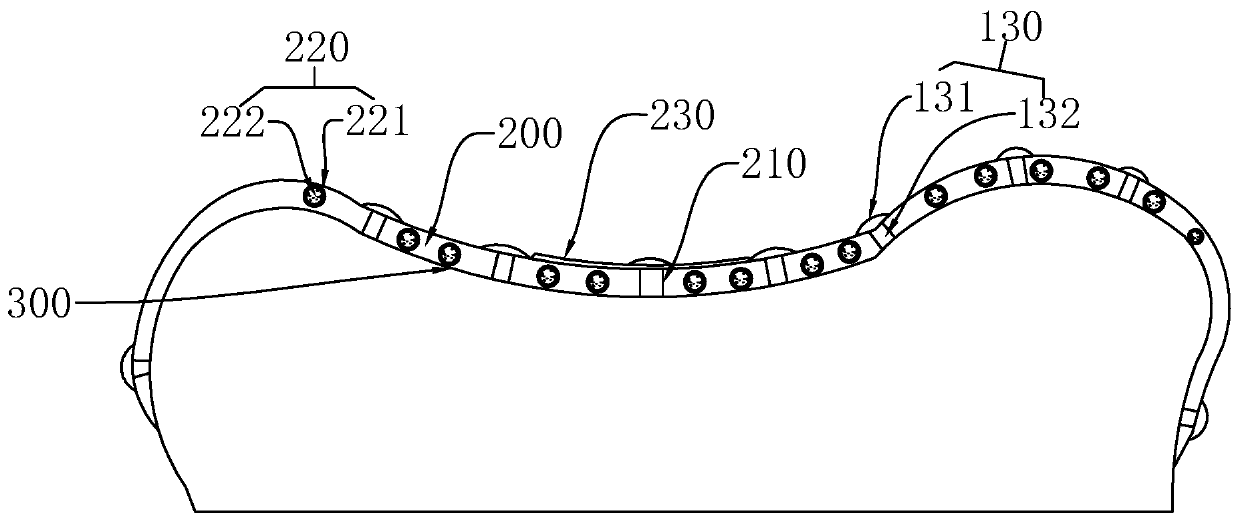

[0052] refer to figure 2 In order to realize the functions of temperature control and massage, several massage fixing parts 130 are arranged on the neck supporting part 110 and the head supporting part 120. A temperature control layer 200 is provided between the surfaces. The temp...

Embodiment 2

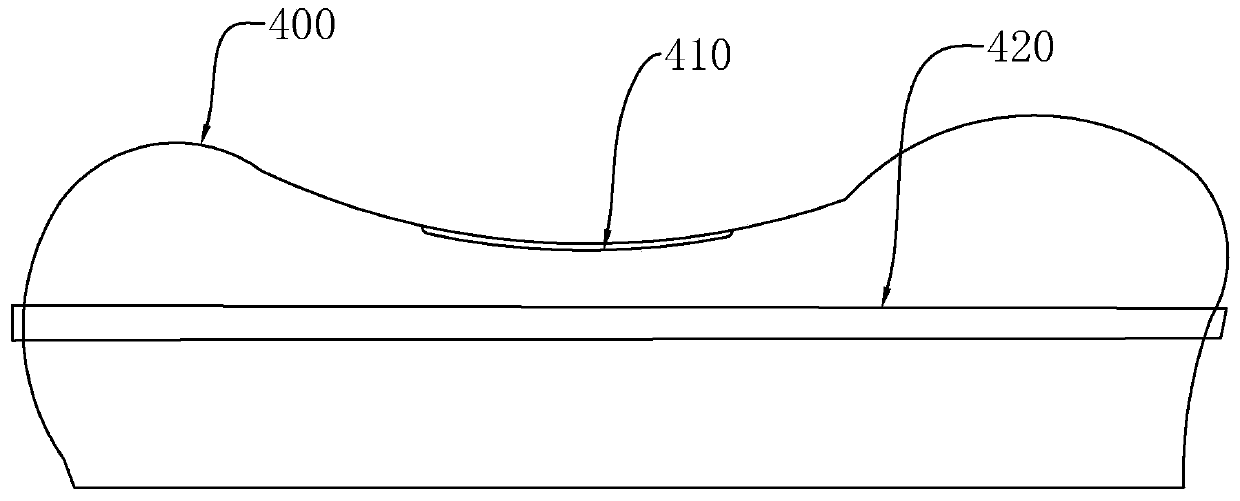

[0068] refer to Figure 4 , in this embodiment, the temperature control layer 200 is a woven fabric 240 of Tencel fibers soaked in PCM liquid, in which several layers are superimposed and connected to each other. Tencel fiber is a new type of artificial cellulose fiber. It comes from cellulose in trees. It is completed under physical action by using organic solvent (NMMO) spinning process. The whole manufacturing process is non-toxic, non-polluting, anti-mite and anti-static At the same time, it has the advantages of strong durability, good elasticity, not easy to wrinkle, easy to take care of and wash, etc. The relative density is 1.5, the moisture regain is 11%, it has strong dry and wet strength, and it is easy to recycle and reuse. The silk fiber tube 221 is filled with PCM particles 222. PCM particles 222 are a kind of phase change material, which can realize the effect of temperature control. At the same time, when it is in a solid state, it can clean the base 100 to kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com