Prefabricated sandwich thermal insulation bay window shear wall board and manufacturing method thereof

A shear wall and sandwich technology, which is applied in the manufacture of tools, building components, climate change adaptation, etc., can solve the problems of surface air bubbles, bay window rotten roots, etc., and achieve the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

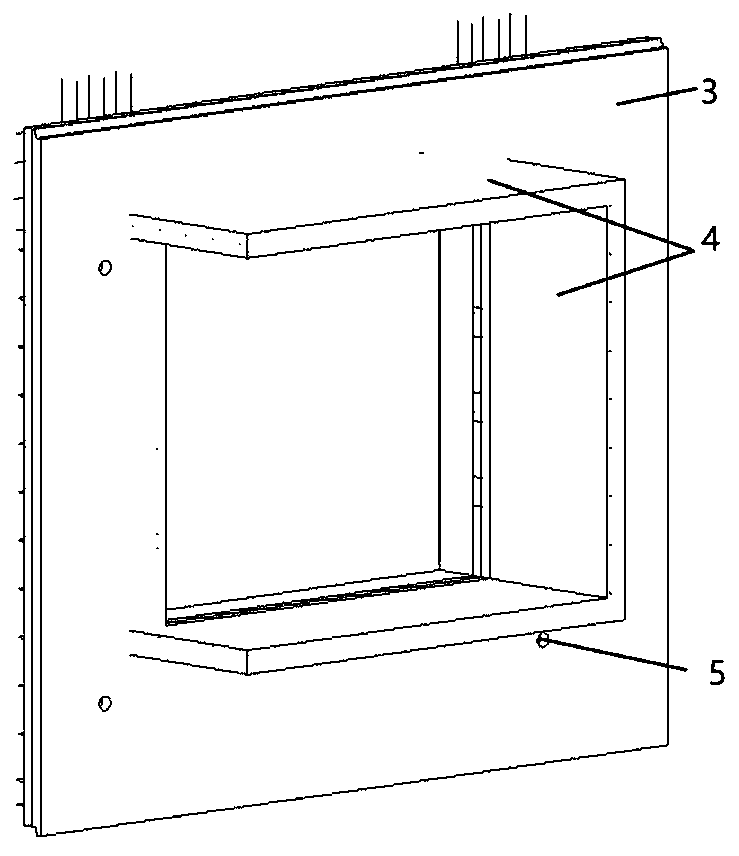

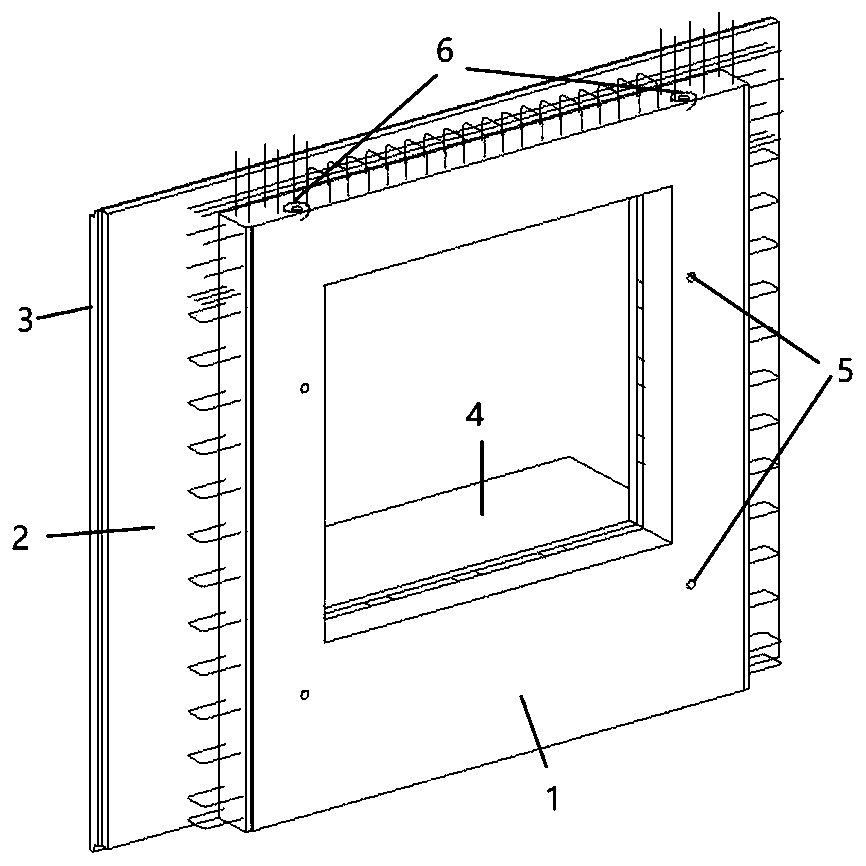

[0027] Embodiment one: by Figure 1 to Figure 3 It is given that the prefabricated sandwich insulation bay window shear wall panel includes a structural layer 1 and an outer layer 3, an insulation layer 2 is arranged between the structural layer 1 and the outer layer 3, and the side wall of the outer layer 3 Set the bay window panel 4, the structural layer 1, the insulation layer 2 and the middle part of the outer layer 3 to reserve a window hole, the three sides of the window hole are provided with a U-shaped bay window panel 4, and the thickness direction of the outer page layer is reserved for more A threaded sleeve 5, two hanging nails 6 extending in the vertical direction are reserved on the top of the structural layer 1, the diameter of each threaded sleeve is between 14-18mm, and the height of the bay window plate is 470- Between 520mm.

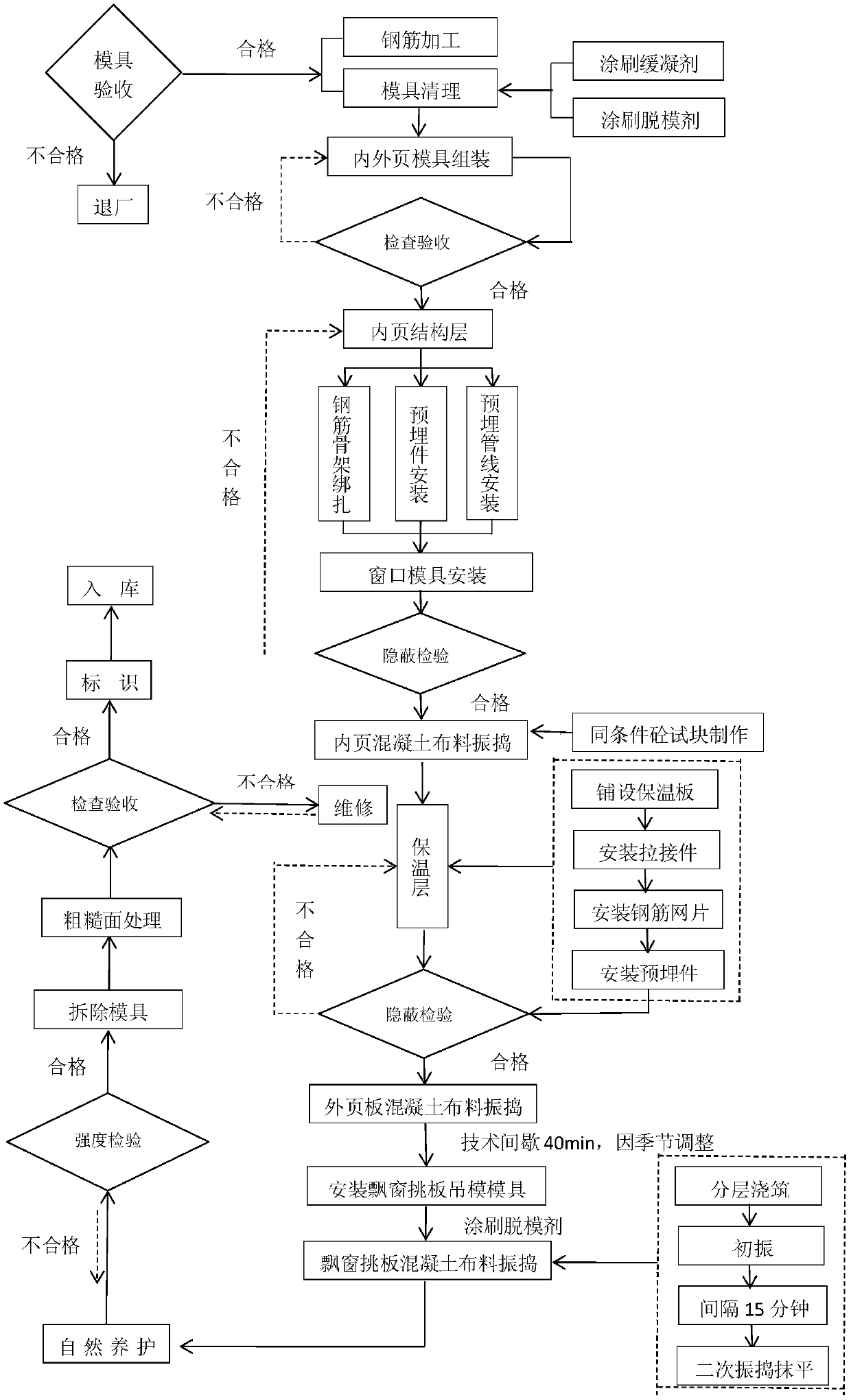

[0028] Production method of prefabricated sandwich insulation bay window shear wall panel:

[0029] S1. Clean the mold table, assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com