Reinforced concrete frame structure

A reinforced concrete and frame structure technology, which is applied to building components, building structures, and earthquake resistance, can solve the problems of increasing the bending capacity of frame beams, and achieve the effects of improving earthquake resistance, light weight, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

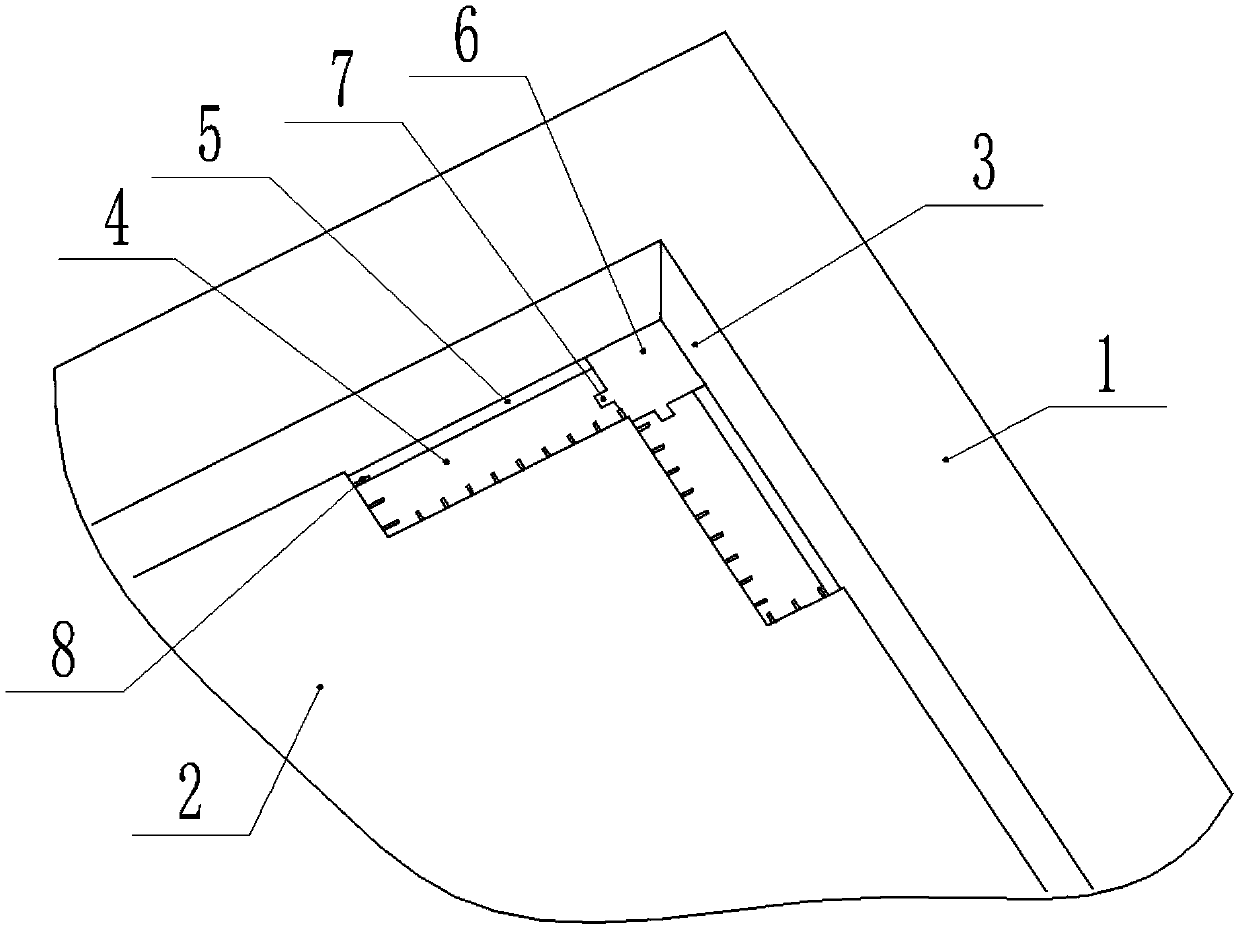

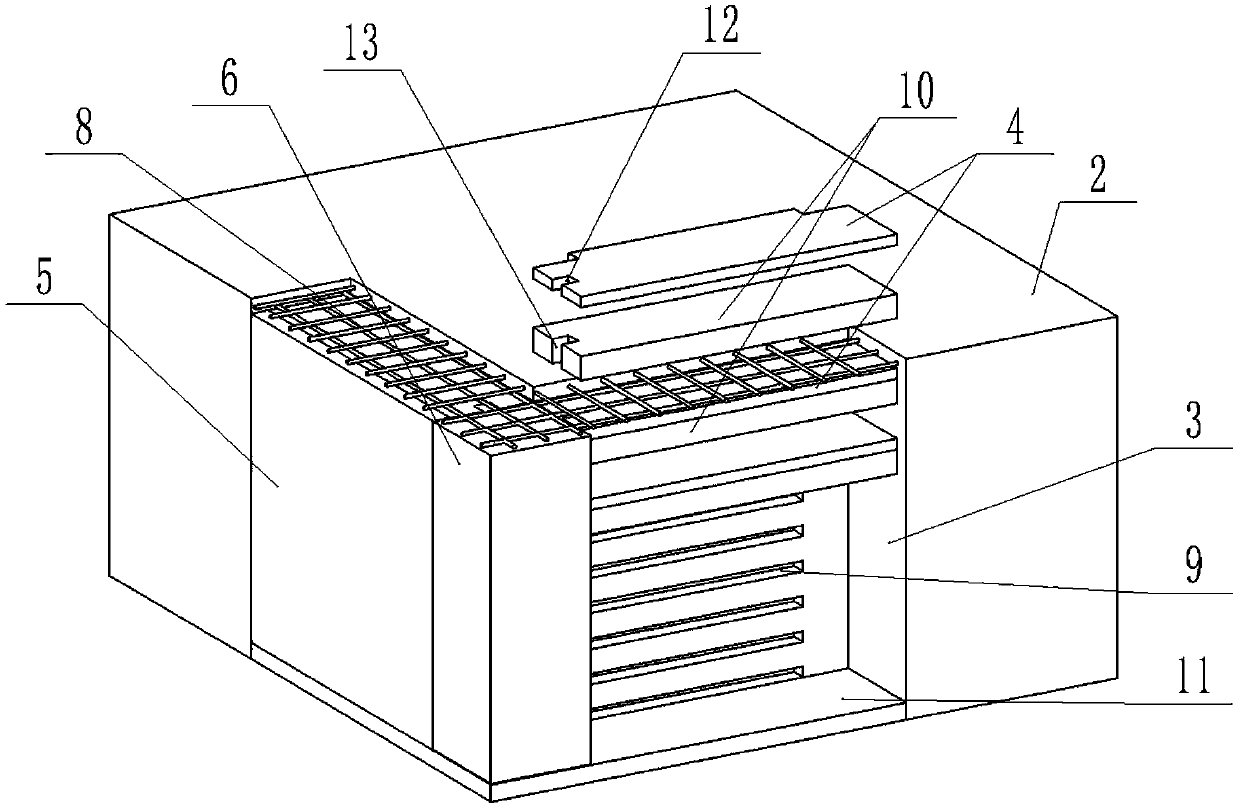

[0021] The reference signs in the drawings of the description include: frame beam 1, cast-in-place floor 2, partition groove 3, extruded board 4, second benzene board 5, post 6, block 7, steel wire 8, slot 9, the first A benzene board 10, a concrete layer 11, a first vertical through groove 12, and a second vertical through groove 13.

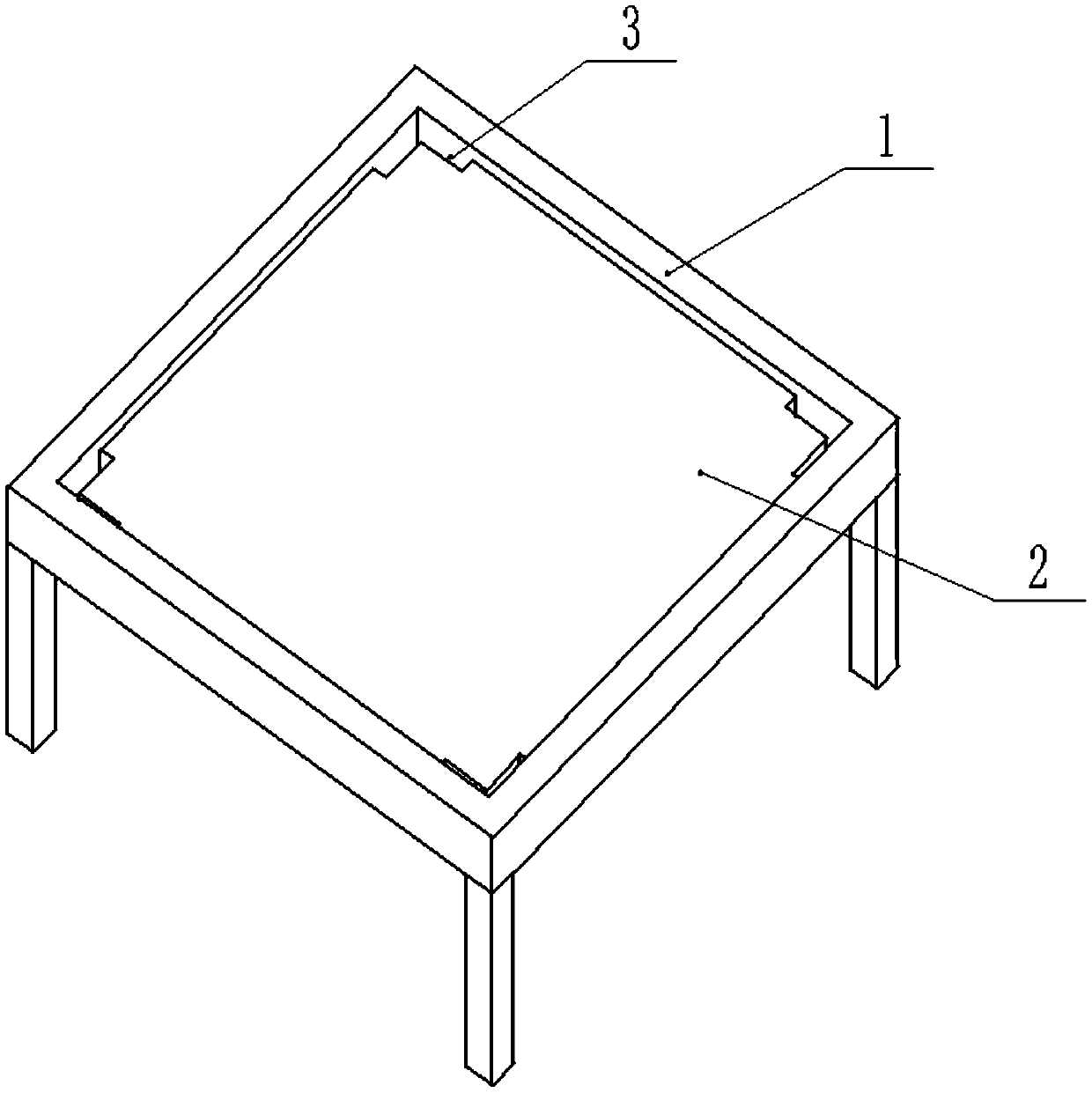

[0022] This example Figure 1-Figure 3 Shown:

[0023] Reinforced concrete frame structure, including cast-in-place floor slab 2 and frame beam 1. The four corners of the cast-in-place floor 2 and the end of the frame beam 1 are connected with an L-shaped partition groove 3, and the lengths of the two sides of the partition groove 3 are respectively equal to 1 / 8 of the span of the cast-in-place floor 2 in the corresponding direction. A filling structure is provided in the groove 3 .

[0024] The filling structure includes a concrete layer 11 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com