Auxiliary device for welding quartz tube branch tube

A branch pipe welding and auxiliary device technology, applied in the direction of manufacturing tools, glass forming, glass reshaping, etc., to achieve the effects of easy positioning and movement, improved stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

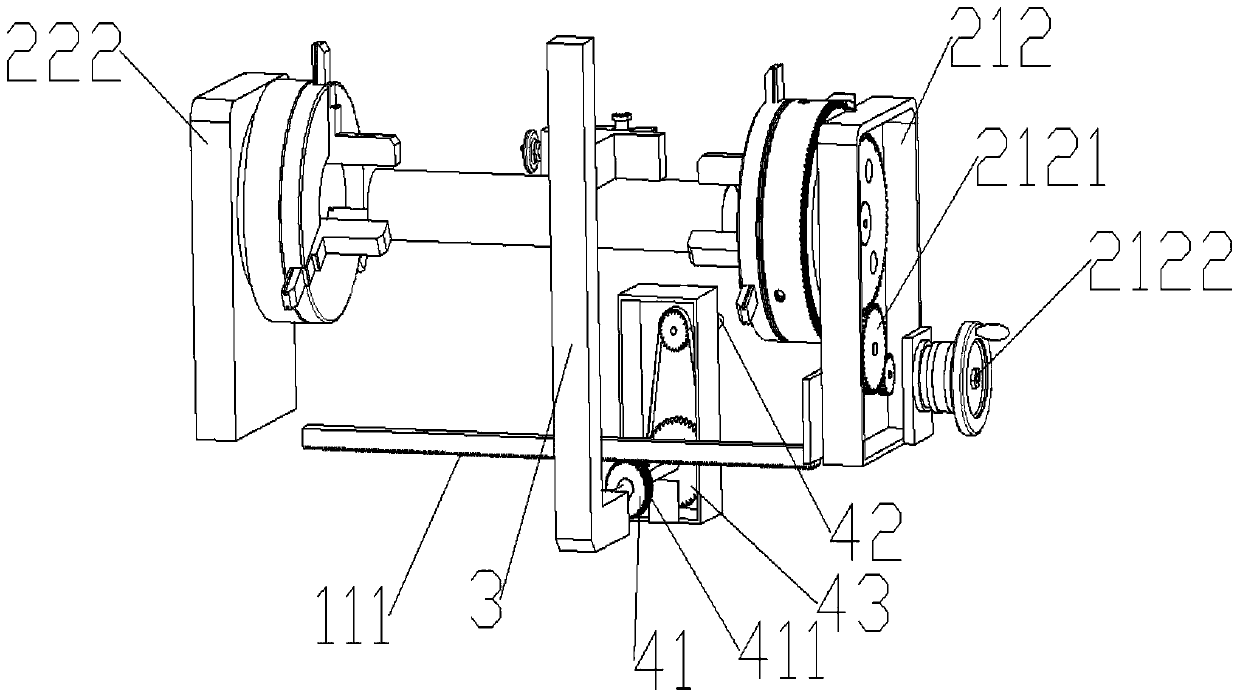

[0042]An auxiliary device for the welding and processing of quartz tube branch pipes, including a bed bearing platform 1, a round pipe chuck clamping device 2, a branch pipe clamping device 3 and a branch pipe clamping translation device 4, and the branch pipe clamping translation device 4 is connected to the bed On the carrying platform 1, the round pipe chuck clamping device 2 includes a first round tube chuck clamping device 21 and a second round tube chuck clamping device 22, and the first round tube chuck clamping device 21 is provided with The first claw 211, the second round pipe chuck clamping device 22 is provided with a second claw 221, the first claw 211 and the second claw 221 correspond to each other, the first round tube chuck clamping device 21 and The second round pipe chuck clamping device 22 is respectively located at both ends of the bed bearing platform 1, the branch pipe clamping device 3 is fixedly connected to the branch pipe clamping translation device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com