Floating and filtering integrated treatment system

A treatment system and treatment tank technology, applied in filtration treatment, flotation water/sewage treatment, special treatment targets, etc., to achieve the effects of stable water quality, improved structure compactness, improved stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

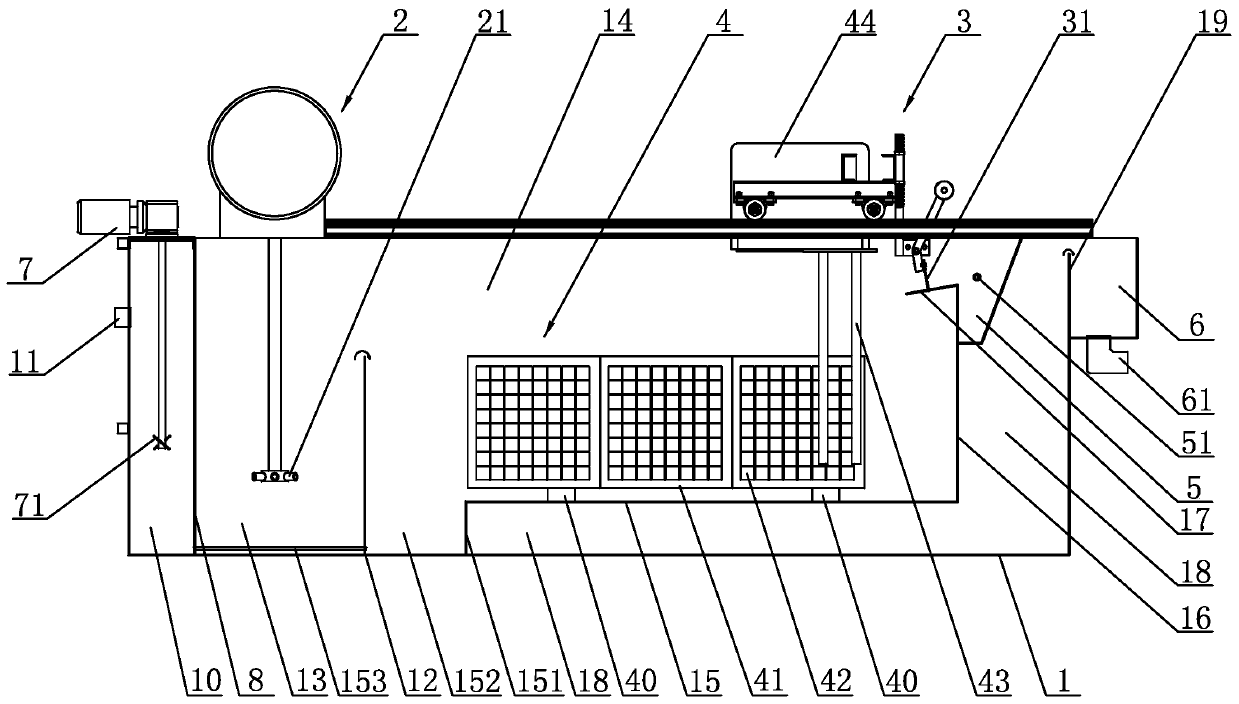

[0021] The floating filtration integrated treatment system of embodiment 1, such as figure 1 As shown, it includes an integrated treatment tank 1, a dissolved air subsystem 2, a slag scraping subsystem 3 and a filtration subsystem 4. The front side wall of the integrated treatment tank 1 is provided with a water inlet 11, and the integrated treatment tank 1 is installed with Upright dividing plate 12, the bottom of dividing plate 12 is fixed on the pool bottom of integrated treatment pool 1, dividing plate 12 is arranged along the width direction of integrated treatment pool 1, and the height of dividing plate 12 is less than integrated treatment pool 1, dividing plate 12 Divide the inner cavity of the integrated treatment pool 1 into a dissolved air area 13 and a filter area 14, the dissolved air area 13 is close to the water inlet 11, the dissolved air subsystem 2 and the slag scraping subsystem 3 are respectively installed on the integrated treatment pool 1, The air outlet ...

Embodiment 2

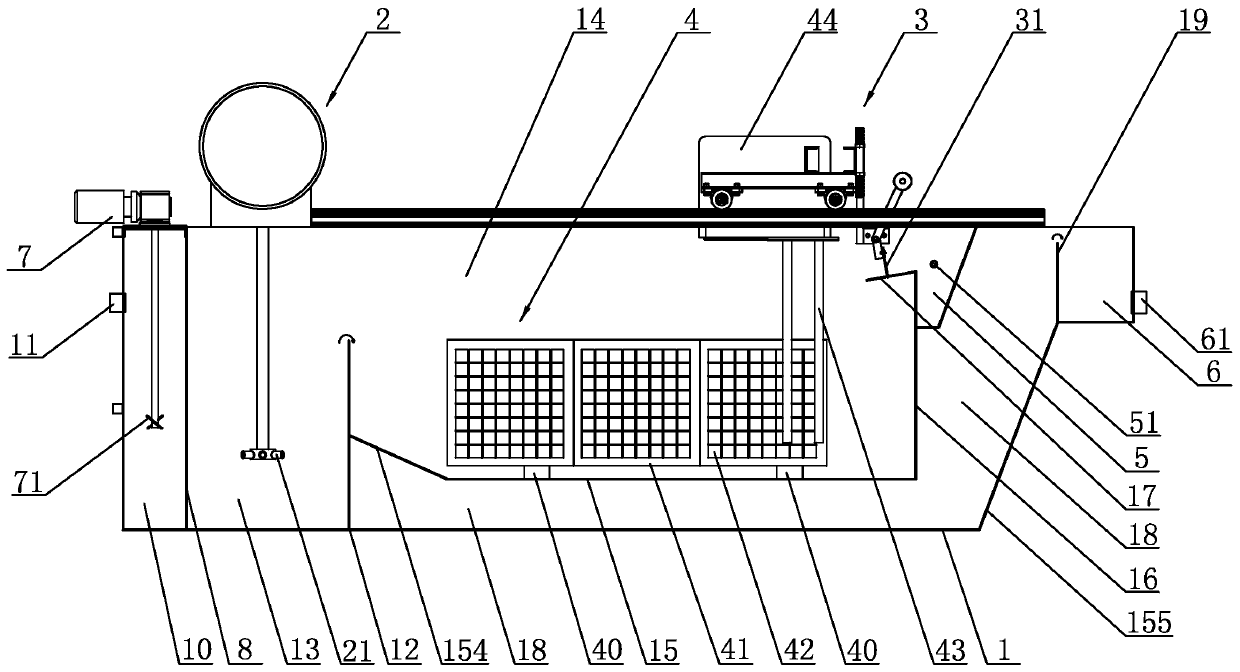

[0027] The floating filtration integrated treatment system of embodiment 2 differs from embodiment 1 in that in embodiment 2, as image 3 As shown, the front side of the mounting plate 15 is fixed on the partition 12, the bottom surface of the mounting plate 15, the rear side of the partition 12, the rear side of the slag retaining plate 16, and the bottom wall and the rear side wall of the integrated treatment tank 1 Enclose the catchment area 18; the front side of the installation plate 15 is the first slant plate 154 obliquely towards the bottom of the filter area 14 from front to back, and the bottom of the rear side wall of the integrated treatment pool 1 is an oblique collection area from back to front. The second inclined plate 155 at the bottom of the water area 18 and the water outlet 61 are arranged on the side of the sump 6 .

Embodiment 3

[0028] The difference between the floating and filtering integrated treatment system of embodiment 3 and embodiment 1 is that in embodiment 3, the filtration subsystem 4 includes a filter frame 41 and a suction and washing device, and the filter frame 41 is equipped with a filter cloth 42, and the suction and washing device It includes a suction cup 43 connected to a suction cup driving device 44 , the suction cup 43 is arranged outside the filter frame 41 , and the suction cup 43 is used for sucking away the filtered material on the filter cloth 42 . Wherein, the filter frame can adopt "a filter core frame" disclosed in ZL 200920122818.5, and the suction and washing device can adopt the "suction and washing device for filter tank" disclosed in ZL 200910100890.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com