Repair method and device of welding defect of inner hole welding in U-shaped pipe type heat exchanger

A technology for welding defects and heat exchangers, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large-scale application of difficult maintenance, difficult operation, and scrapped heat exchangers, and promote large-scale application. , strong process adaptability, and the effect of improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

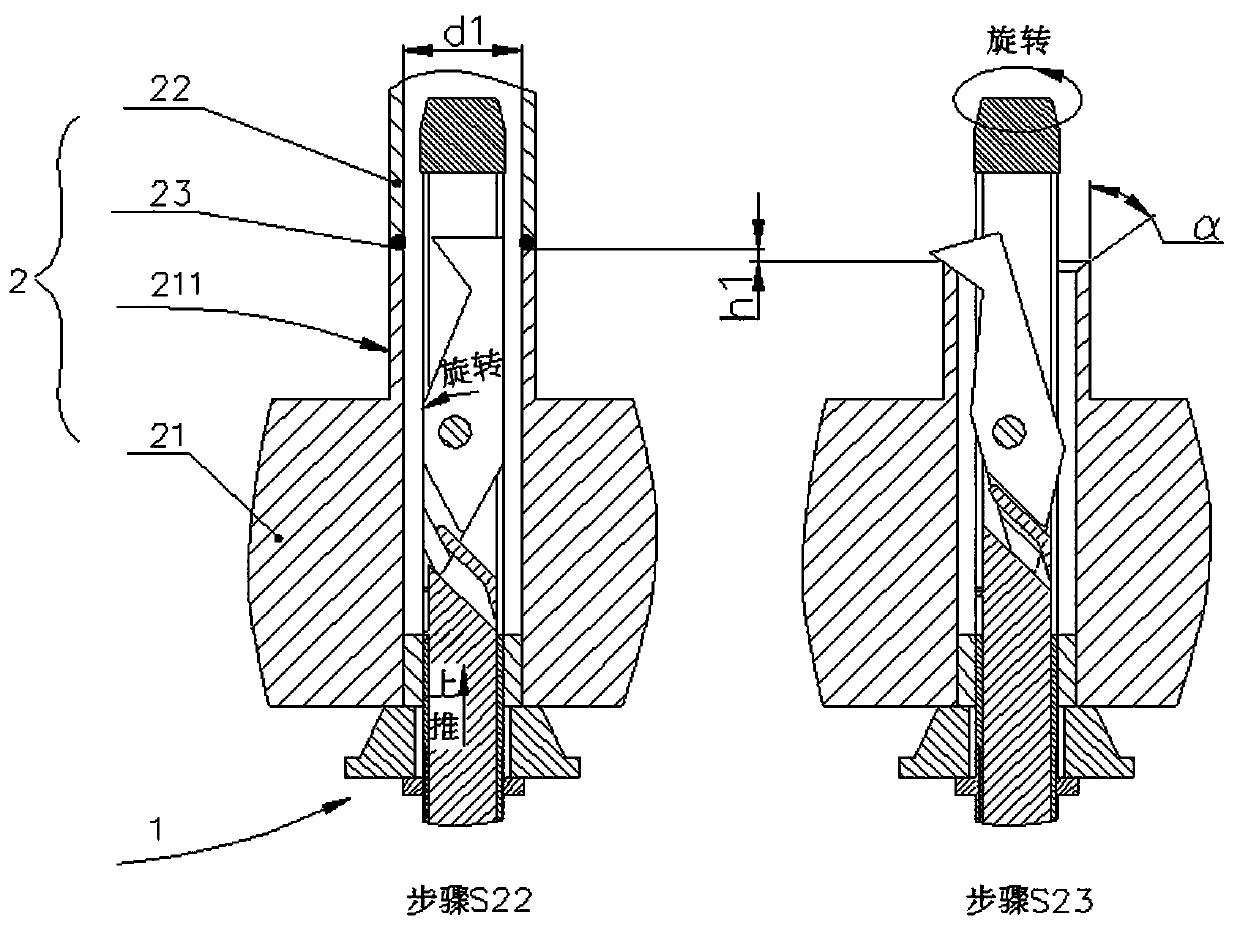

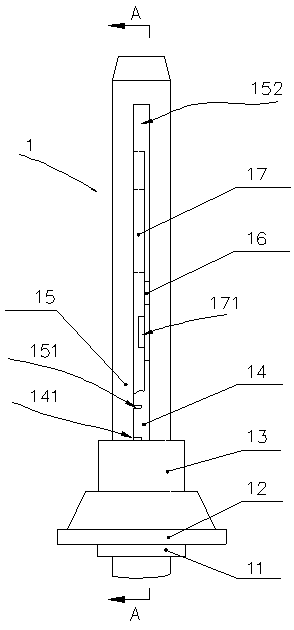

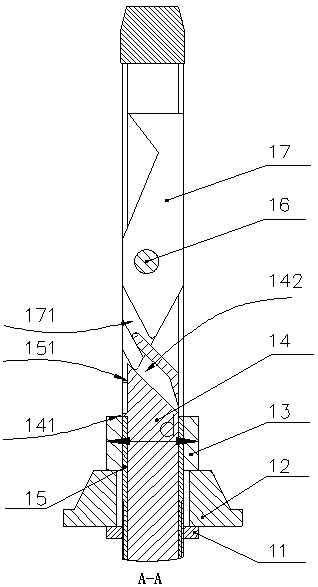

[0032] combine Figure 1~4 This embodiment will be described. This embodiment provides a repair method for inner hole welding defects in titanium alloy U-shaped tube heat exchangers. The inner hole welding seams 23 that generate defects are in the form of a butt joint structure. The 211 sets of ring-shaped bosses on the top are welded against each other, and the inner holes are welded by inner hole welding. After each row of heat exchange tubes is welded, visual inspection and radiographic flaw detection are carried out, and the next row is replaced after confirming that there are no welding defects. Welding of heat pipes. After the welding of a certain row of heat exchange tubes is completed, visual inspection finds that there is a phenomenon of welding leakage, and the width of the welding leakage point is greater than the width of the inner hole welding seam 23 . According to the existing inner hole welding technology, the repair welding method cannot be used to realize t...

Embodiment 2

[0057] This embodiment provides a repair method for inner hole welding defects in a stainless steel U-shaped tube heat exchanger, which is basically the same as the repair method provided in Example 1, and only the differences will be further described below.

[0058] The welding defect of the inner hole in the stainless steel U-shaped tube heat exchanger is a single pore, and the size of a single pore exceeds 1 / 2 of the wall thickness of the U-shaped heat exchange tube, which cannot meet the requirements of "qualified according to NB / T 47013.2 Class II" Flaw detection requirements. When using the rework device 1 to completely remove the generated defects and open a new inner hole welding groove on the tube sheet 21, the cutting position is set at a position about 1mm below the edge of the weld. Porosity, on the other hand, is to remove the weld seam together with the heat-affected zone, so as to avoid the deterioration of the performance of the welded joint caused by the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com