Measuring method of real-time execution rate of tobacco leaf curing process

A technology of curing process and real-time execution, applied in tobacco, measuring device, tobacco processing, etc., can solve the problems of inability to record short-term temperature drop, large subjective impact, poor objectivity, etc., to reduce time costs and related operating expenses , easy to monitor, improve management and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

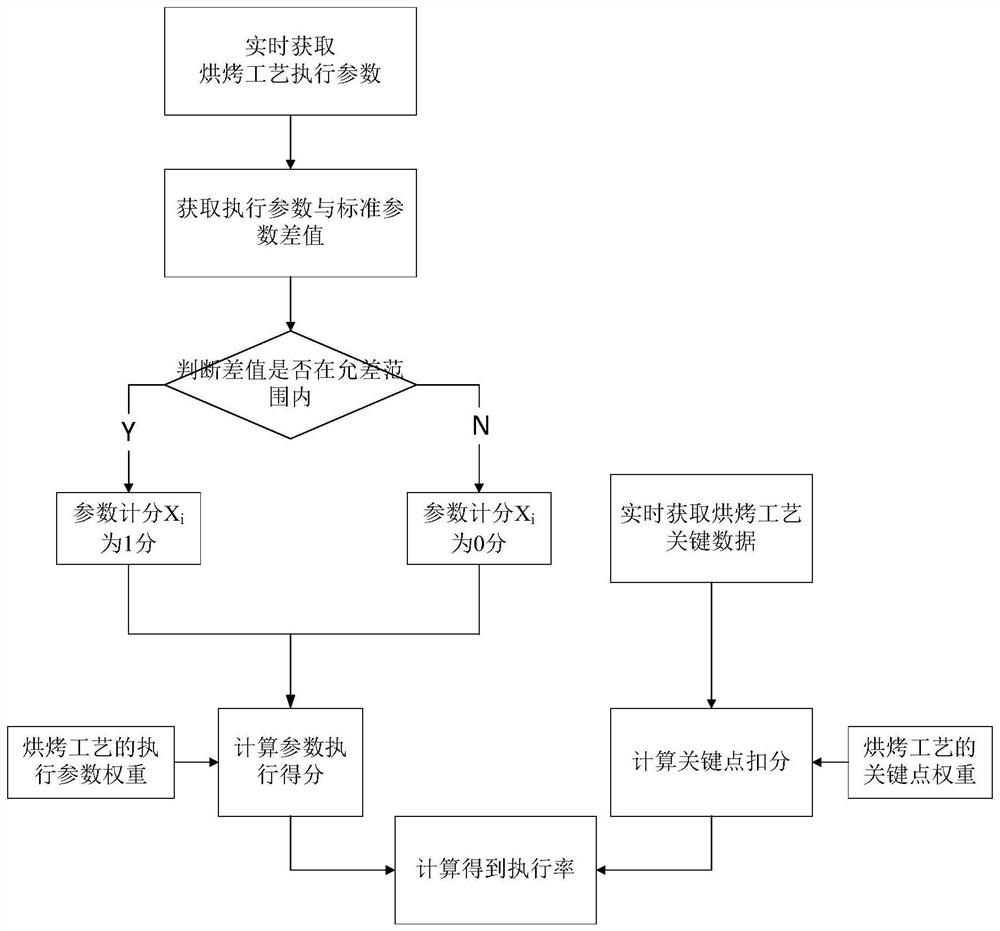

[0068] Include the following steps:

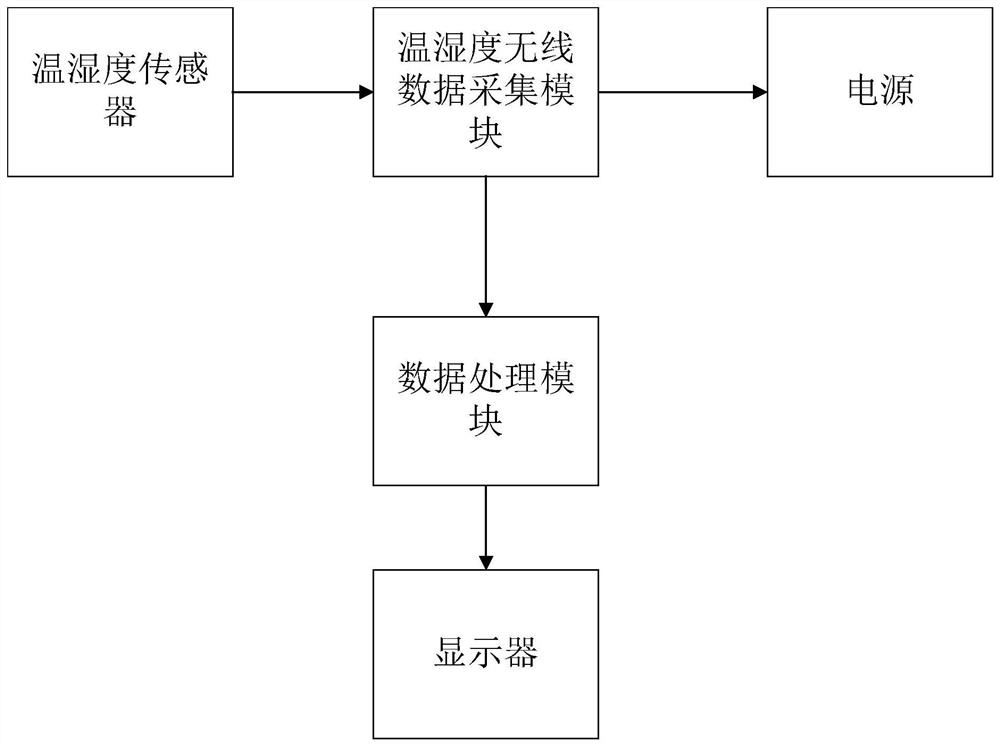

[0069] Step 1: Connect the barn temperature and humidity wireless data acquisition module (hereinafter referred to as the data acquisition module) in series between the barn temperature and humidity sensor and the barn controller. After the data of the GPRS module is shunted, the signal is output to the oven controller synchronously. The hardware circuit of the digital acquisition module consists of a power supply circuit, a GPRS circuit and a main control circuit

[0070] Power circuit: The module takes power from the sensor interface of the barn controller. The power chip XC6206P331MR converts +5V to +3.3V to supply power for the main control circuit. The power chip TP4056 converts +5V to +4.2V to supply power for the GPRS module. Supercapacitor energy storage is used to ensure the high current demand when the GPRS module sends data.

[0071] GPRS circuit: GPRS module adopts SIM800C, and SIM800C module communicates with MCU UART.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com