Blasting construction method suitable for hydraulic pressure smooth surface of granitic geological III-grade surrounding rock

A technology of smooth blasting and construction method, applied in blasting, earth-moving drilling, mining equipment and other directions, can solve the problems of increased control difficulty of over and under excavation, unsatisfactory construction footage, and high dust concentration, achieving good shock absorption effect and saving The effect of ventilation time and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation methods and specific construction processes are given, but the scope of protection of the present invention is not limited to the following Mentioned examples.

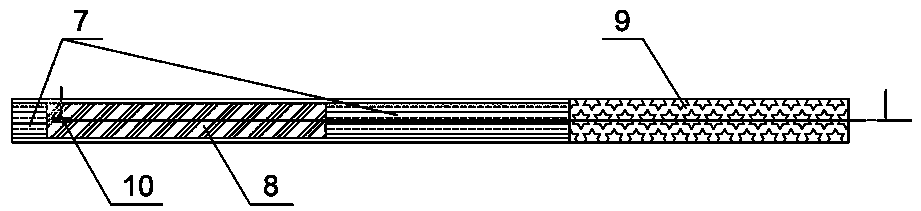

[0035] Such as Figure 1-7 As shown, the construction method of the present invention suitable for granite geological grade III surrounding rock hydraulic pressure smooth blasting includes the following construction steps:

[0036] In the first step, various types of blastholes are excavated on the blasting surface according to the grade and footage of the surrounding rock. In this example, the area of the blasting surface is 59.5m 2 , The height of the blasting section is 6.74m, and the bottom of the arch foot is 9.72m wide. Two rows of central cut holes 1 are excavated at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com