A cylindrical anti-backflow loop heat pipe capillary pump assembly for spacecraft

A countercurrent loop and cylindrical technology, which is applied in the field of spacecraft thermal control, can solve problems such as difficult liquid reservoir temperature detection, achieve the effects of increasing the contact area, saving on-orbit resources, and improving heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

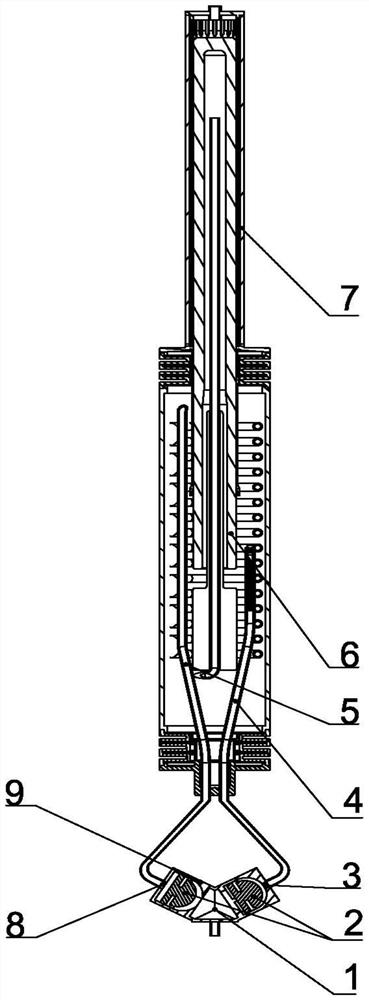

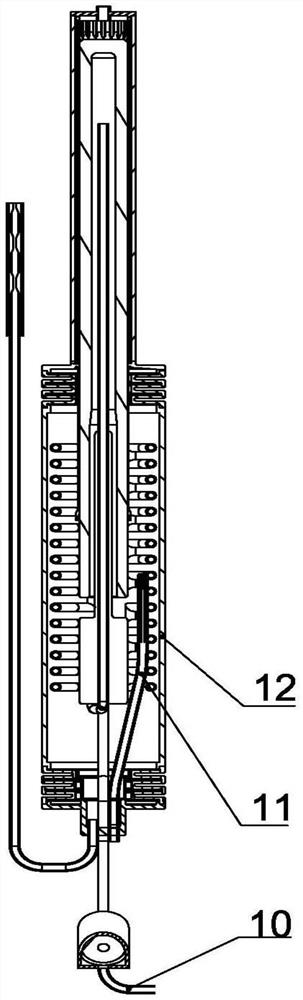

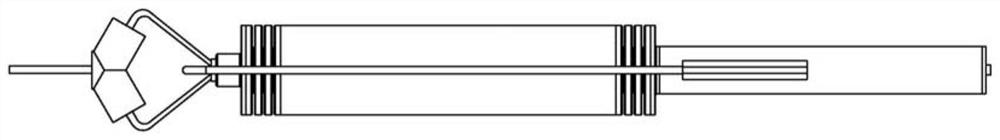

[0025] Aiming at the problem of backflow of working medium caused by the temperature change of the cooling surface of the existing space loop heat pipe system from high to low, a cylindrical anti-backflow loop heat pipe capillary pump assembly for spacecraft is proposed, which has good heat transfer performance. At the same time, it can effectively prevent the backflow of liquid-phase working fluid.

[0026] like Figure 1 to Figure 5 As shown, the cylindrical anti-backflow loop heat pipe capillary pump assembly for spacecraft includes: backflow compensation device 1, serpentine tube 5, temperature measuring tube 11, backflow tube 4, liquid return tube 10, capillary core 6, evaporator 7, storage Liquid container 12;

[0027] The liquid reservoir 12 is connected to the evaporator 7, part of the capillary 6 is installed in the liquid reservoir 12, and the other part is installed in the evaporator 7; the bottom port of the backflow compensation device 1 is connected to the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com