Forming method of sealing membrane sleeve

A technology of sealing film and film thickness, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor sealing effect, difficult application of sealing materials, poor film-forming effect, etc., to reduce the failure rate of sealing, The generation method is novel and unique, and the generation method is simple and practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

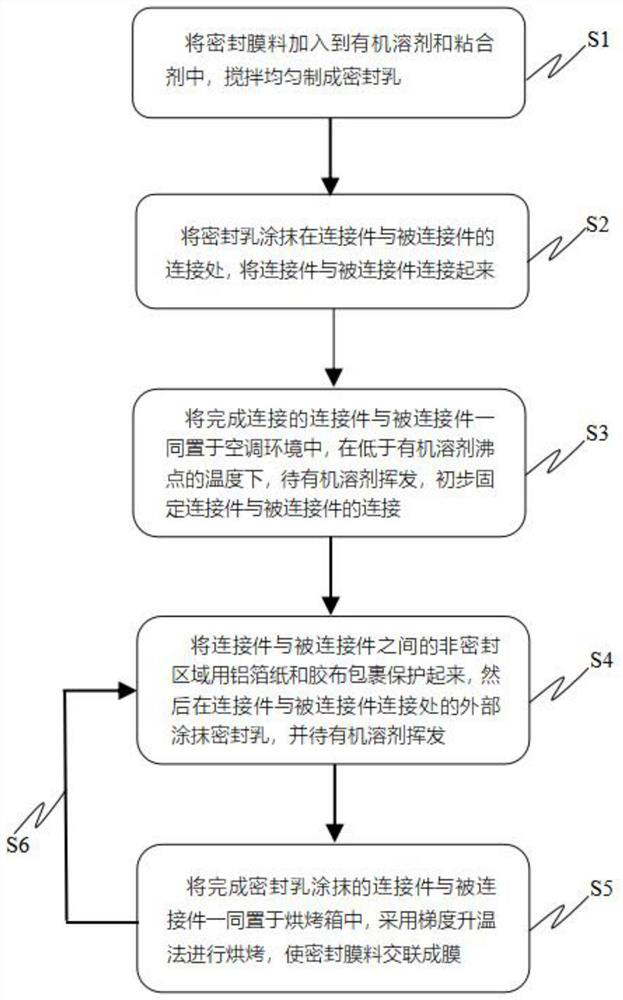

[0055] Such as figure 1 A schematic flow chart of a method for generating a sealing film sleeve provided by an embodiment of the present invention is shown in the following:

[0056] A method for generating a sealing membrane sleeve, which is used to generate a sealing membrane sleeve at the joint between a connecting piece and a connected piece, comprising the steps of:

[0057] S1) adding the sealing film material into the organic solvent and the binder, stirring evenly to make a sealing emulsion;

[0058] S2) apply the sealant to the joint between the connecting piece and the connected piece, and connect the connecting piece and the connected piece;

[0059] S3) place the connecting piece and the connected piece that have been connected together in an air-conditioned environment, and at a temperature lower than the boiling point of the organic solvent, wait for the organic solvent to volatilize, and initially fix the connection between the connecting piece and the connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com