Screw excited hydraulic harmonic high-power enhancement vibrator

A vibrator and screw technology, applied in the direction of drilling with vibration, can solve the problems affecting the speed and cost of oilfield exploration and development, increase in drilling cost, lack of vibration power, etc. , The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

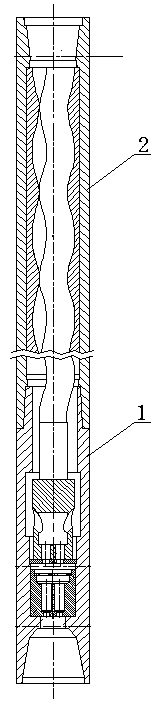

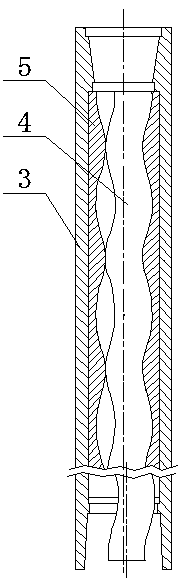

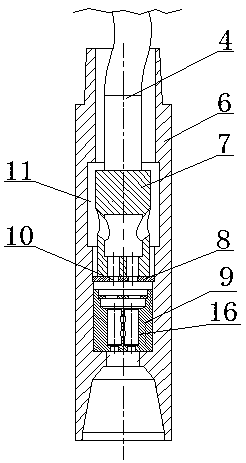

[0022] The hydraulic harmonic high-amplification enhanced vibrator excited by the screw includes a vibrator body 1 and a screw power sub-joint 2; the screw power sub-joint 2 is composed of a sub-joint housing 3 and a screw rotor 4 and a screw stator 5 inside the sub-joint housing 3 , The vibrator body 1 and the screw power nipple 2 are screwed together. The vibrator body 1 is composed of a vibrator shell 6, a screw rotor head 7, a fixed cut-off block 8 and a resonance reinforcement 9; It is a circular plate-shaped body, and the central part of the fixed cut-off block 8 is provided with an overflow hole 10 corresponding to the flow channel hole 12 of the pulse nozzle.

[0023] A pulse chamber 11 is provided in the stepped through hole above the fixed cut-off block 8, and a screw rotor head 7 is installed in the pulse chamber 11. The screw rotor head 7 is cylindrical, and the middle part of the screw rotor head 7 is provided with a confluence chamber 20 for converging flow. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com