A kind of production process of regenerated dori slub silk

A production process, slub yarn technology, applied in textiles, papermaking, yarn, etc., can solve problems such as difficult oil control, throwing out of the oil tank, equipment pollution, etc., to achieve automatic adjustment, high oiling efficiency, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

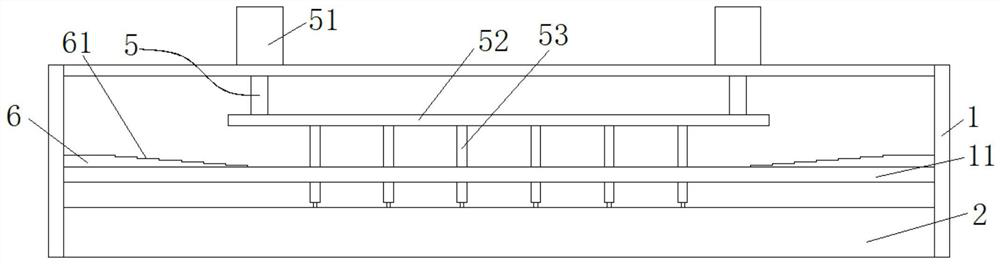

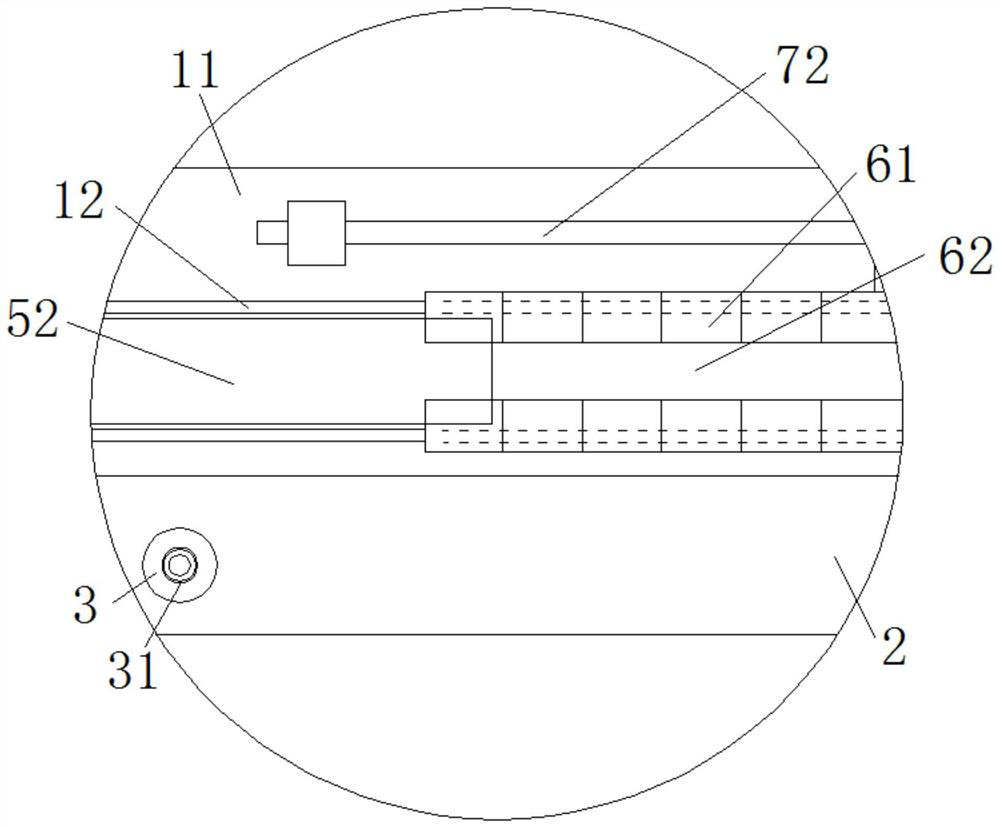

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0021] A production process of regenerated dori slub yarn, comprising the following steps: heating the regenerated semi-dull MOY introduced through the original silk rack and the zero roller and the regenerated semi-dull FDY introduced through the original silk rack through a roller, and then passing through the cooling plate After cooling, it is fed into the false twister for twisting. The twisted tow goes through the second roller, network nozzle, auxiliary roller, shaping heat box, third roller, and then oiled by the oiling system, and finally winds up to form a dori slub DTY. Regenerated semi-dull MOY and recycled semi-dull FDY are produced by Zhejiang Jiaren New Material Co., Ltd. The physical performance indexes of regenerated semi-dull MOY and regenerated semi-dull FDY are shown in Table 1.

[0022] Table 1

[0023]

[0024] The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com