A kind of cellulomonas and method and application thereof for preparing microbial flocculant

A technology of microbial flocculant and cellulomonas, which is applied in the biological field, can solve the problems of high production cost and unstable flocculation performance, and achieve the effects of cost saving, good flocculation performance and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

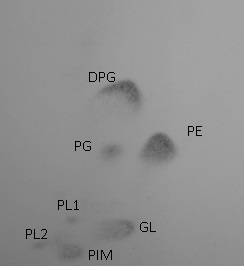

[0042] Isolation and Identification of Strain 40-2

[0043] 1. Isolation and purification of strain 40-2

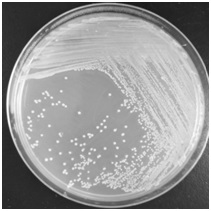

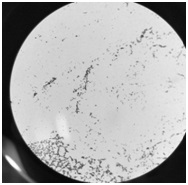

[0044] The samples used in this embodiment are collected from animal hair, feces, and blood. The screening of Cellulomonas 40-2 adopts the plate streaking method, wherein the liquid culture conditions are 37 ° C, the shaking table speed is 155 rpm, and the solid plate culture conditions are Culture in a biochemical incubator at 37°C. Concrete separation and purification are carried out according to the following steps:

[0045] 1) Enrichment, isolation and purification of strains: under sterile conditions, take 1.0 g of the sample and put it into a 10 mL plastic centrifuge tube containing 5 mL of enrichment medium, and incubate at 37°C for 24 hours. The culture solution was streaked on the surface of LB solid medium, and cultured at 37°C for 48h. Pick a yellow single colony with a smooth and viscous surface, streak and purify it multiple times, and store it in a magnet...

Embodiment 2

[0062] Preparation process of microbial flocculant produced by Cellulomonas 40-2 strain

[0063] Cellulomonas 40-2 was inoculated into the fermentation medium, the culture temperature was 37°C, and the shaker was cultivated at 155rpm for 48h to obtain the fermentation broth containing the microbial flocculant, centrifuged at 8000rpm for 5min, the supernatant was discarded, and the bacterial precipitate was retained , the precipitate was dissolved and resuspended in PBS, washed twice, centrifuged at 8000r / min for 5min, and then the precipitated bacteria were resuspended in PBS solution, and then ultrasonically crushed by a cell ultrasonic breaker. The broken liquid obtained after half an hour was the microbial flocculant.

[0064] Specifically, in this embodiment, the composition of the fermentation medium involved is (per liter): CMC-Na 10g, KH 2 PO 4 1g, K 2 HPO 4 1g, MgSO 4 0.2g, (NH 4 ) 2 SO4 3g, NaCl1g distilled water 1000mL, pH7.0-8.0, sterilized at 121°C for 30m...

Embodiment 3

[0066] Study on the distribution of flocculation activity produced by Cellulomonas 40-2 strain

[0067] Prepare kaolin suspension (4g / L) as simulated wastewater to test the flocculation performance of microbial flocculants. The specific method is: put 100mL kaolin suspension (4g / L) in a 150mL beaker, add 1mL microbial flocculant, stir rapidly at room temperature for 1min, stir slowly for 2min, and stand still for 10min. The absorbance was measured at a wavelength of 550nm by a spectrophotometer, and distilled water was used to replace the microbial flocculant as a control group.

[0068] The formula for calculating the flocculation rate is: flocculation rate=(A-B) / A×100% where A is the absorbance of the control group at 550nm, and B is the absorbance of the experimental group at 550nm. Calcium chloride is a common coagulant aid for microbial flocculants, use 10% CaCl 2 1mL was used as a coagulant aid, and the kaolin suspension was added together with the microbial flocculant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com