Cleaning method for OLED evaporation equipment tantalum crucible surface material residues

A technology of surface material and tantalum crucible, which is applied in the field of OLED panel production, can solve problems affecting the purity of evaporation materials and the stability of product yield, and achieve the effects of increasing the number of repeated cleanings, easy cost control, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

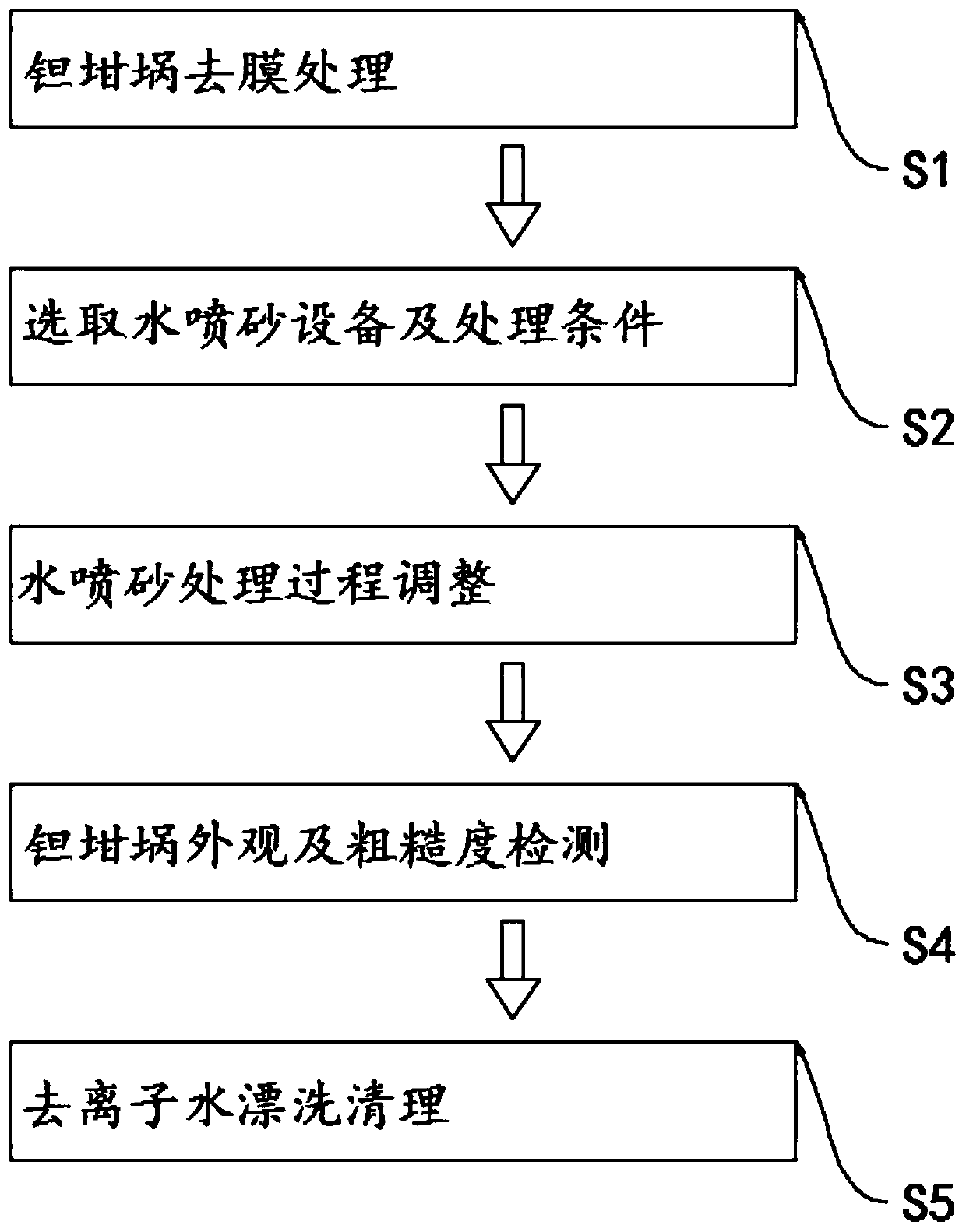

[0041] A method for cleaning material residues on the surface of a tantalum crucible of OLED evaporation equipment provided by a preferred embodiment of the present invention comprises the following steps:

[0042] Remove the film layer on the inner surface and outer surface of the tantalum crucible after evaporation, so that the body and the mark are revealed;

[0043] According to the size and structure of the tantalum crucible parts, select the corresponding water blasting equipment;

[0044] According to the precision requirements and structural characteristics of the tantalum crucible, select the corresponding sand material and blasting pressure for water blasting treatment;

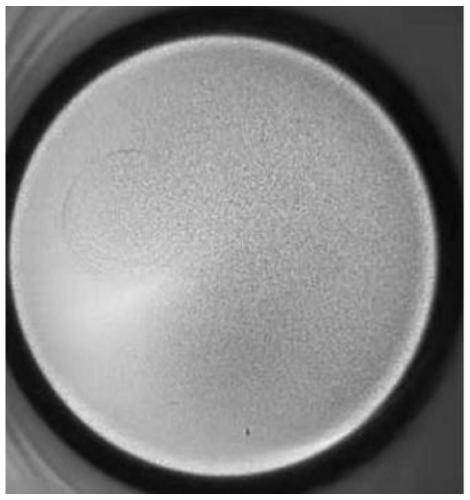

[0045] Appearance and roughness inspection of tantalum crucibles treated by water blasting;

[0046] Rinse the qualified tantalum crucible with deionized water.

[0047] The material of the sand material is alumina. The particle size of the sand material is 50-80 microns.

[0048] The specific c...

Embodiment 2

[0054] Another embodiment of the present invention provides a method for cleaning material residues on the surface of a tantalum crucible of OLED evaporation equipment, comprising the following steps:

[0055] Remove the film layer on the inner surface and outer surface of the tantalum crucible after evaporation, so that the body and the mark are revealed;

[0056] According to the size and structure of the tantalum crucible parts, select the corresponding water blasting equipment;

[0057] According to the precision requirements and structural characteristics of the tantalum crucible, select the corresponding sand material and blasting pressure for water blasting treatment;

[0058] Appearance and roughness inspection of tantalum crucibles treated by water blasting;

[0059] Rinse the qualified tantalum crucible with deionized water.

[0060] The material of the sand material is silicon dioxide.

[0061] The specific conditions of the water blasting treatment are: the sand...

Embodiment 3

[0066] Another embodiment of the present invention provides a method for cleaning material residues on the surface of a tantalum crucible of OLED evaporation equipment, comprising the following steps:

[0067] Remove the film layer on the inner surface and outer surface of the tantalum crucible after evaporation, so that the body and the mark are revealed;

[0068] According to the size and structure of the tantalum crucible parts, select the corresponding water blasting equipment;

[0069] According to the precision requirements and structural characteristics of the tantalum crucible, select the corresponding sand material and blasting pressure for water blasting treatment;

[0070] Appearance and roughness inspection of tantalum crucibles treated by water blasting;

[0071] Rinse the qualified tantalum crucible with deionized water.

[0072] The material of the sand material is alumina.

[0073] The specific conditions of the water blasting treatment are: the sand materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com