Electrode assembly and lithium ion battery

A lithium-ion battery and electrode assembly technology, which is applied in the manufacture of electrode carriers/collectors, non-aqueous electrolyte batteries, and electrolyte batteries, and can solve problems such as low lithium utilization, affecting the DC impedance of lithium-ion batteries, and increasing the negative electrode impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

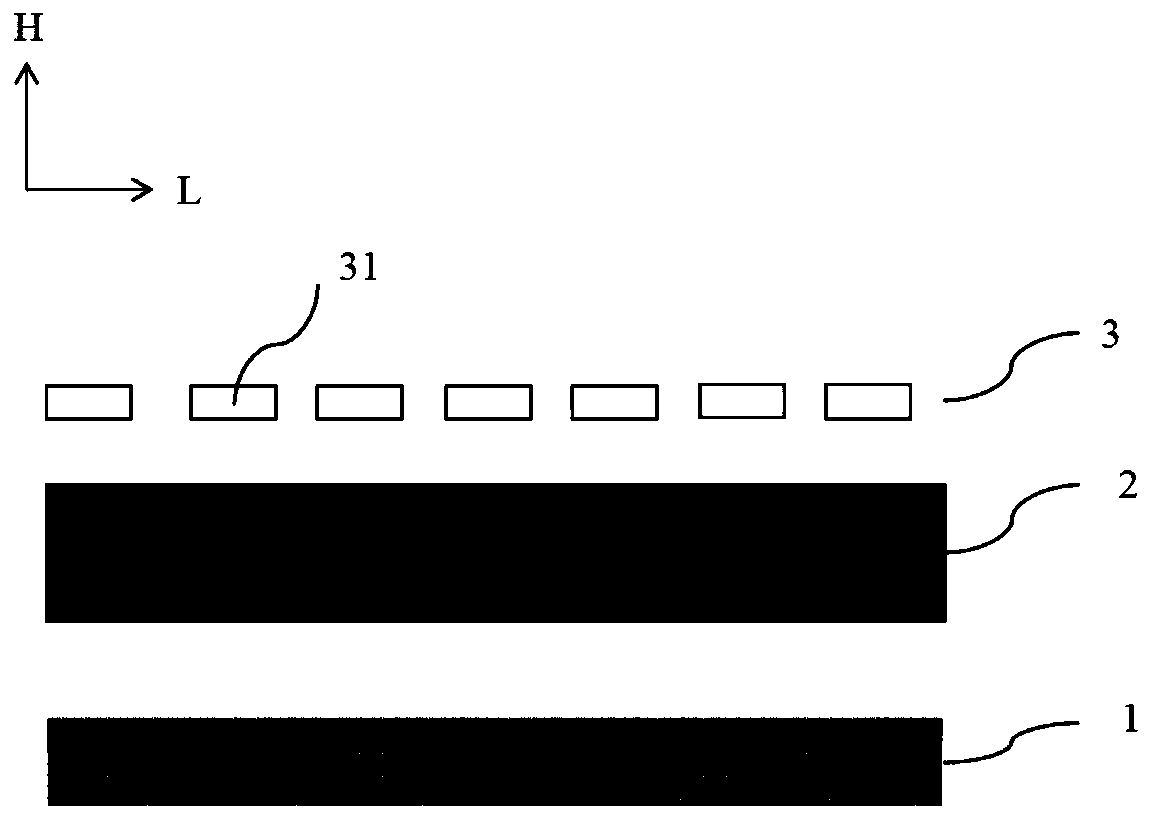

[0073] (1) Preparation of positive pole piece

[0074] Mix the positive electrode active material lithium iron phosphate (the reversible gram capacity is 139mAh / g), the conductive agent acetylene black, and the binder PVDF at a mass ratio of 94:4:2, add the solvent N-methylpyrrolidone, stir and mix evenly to obtain The positive electrode slurry is then coated on both surfaces of the positive electrode current collector aluminum foil, then dried and cold pressed to obtain the positive electrode sheet, wherein the coating quality of the positive electrode slurry is 0.198g / 1540.25mm 2 (Based on mass excluding solvent).

[0075] (2) Preparation of negative pole piece

[0076] Mix graphite (reversible gram capacity of 340mAh / g) as the negative active material, conductive agent acetylene black, and binder SBR+CMC according to the mass ratio of 95:1.5:3.1:0.4, add solvent deionized water, fully stir and mix evenly to obtain The negative electrode slurry is then coated on both surfa...

Embodiment 2

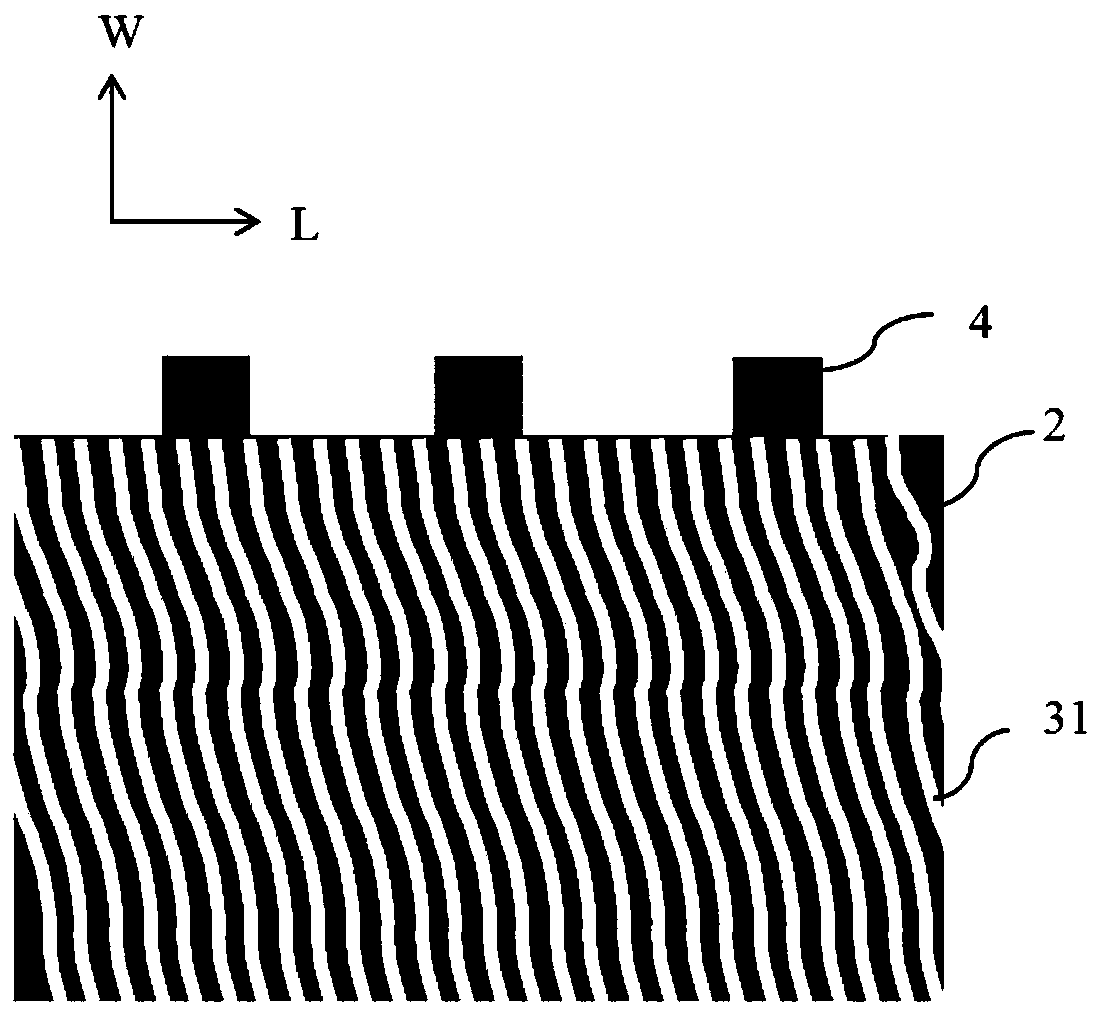

[0094] The preparation process of the lithium-ion battery is the same as in Example 1, the difference is that in the preparation of the negative electrode sheet, several wavy strip-shaped lithium foils are replaced with thin strip-shaped lithium foils and are laminated at equal intervals by rolling. On the surface of the negative electrode active material layer, discontinuous metal lithium layers distributed at intervals are formed.

[0095] Among them, the mass of lithium metal layer is 3.05mg / 1540.25mm 2 , the width of each slender lithium foil is 0.5 mm, the distance between two adjacent slender lithium foils is 0.5 mm, the angle between the length direction of each slender lithium foil and the length direction of the negative electrode sheet are about 85°, and along the length direction of each elongated lithium foil, the surface of the negative electrode active material layer is completely covered by the lithium foil.

Embodiment 3

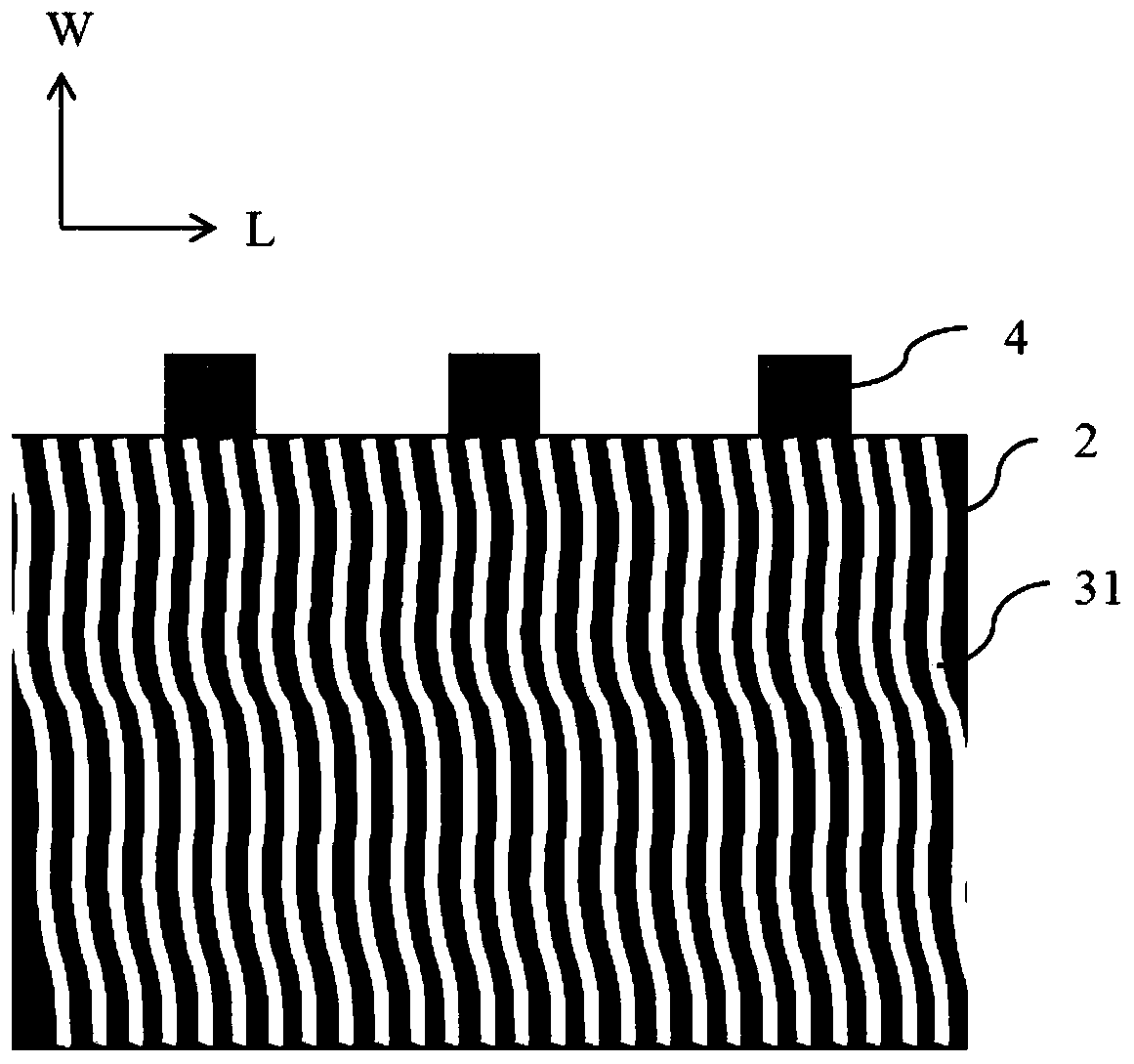

[0097] The preparation process of the lithium-ion battery is the same as in Example 1, the difference is that in the preparation of the negative electrode sheet, several wavy strip-shaped lithium foils are replaced with strip-shaped lithium foils and are composited to the negative electrode at equal intervals by rolling. On the surface of the active material layer, discontinuous metal lithium layers distributed at intervals are formed.

[0098] Among them, the mass of lithium metal layer is 3.05mg / 1540.25mm 2 , the width of each strip-shaped lithium foil is 0.5mm, the distance between two adjacent strip-shaped lithium foils is 0.5mm, and the included angle between the length direction of each strip-shaped lithium foil and the length direction of the negative electrode sheet is about 92°, and along the length direction of each strip-shaped lithium foil, the surface of the negative electrode active material layer is completely covered by the lithium foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com