Low-reflection-color neutral low-stress resin lens and preparation method thereof

A resin lens, low-stress technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve problems such as poor temperature resistance, poor temperature resistance and environmental resistance, and limited use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a specific embodiment, the method for preparing the above-mentioned low-reflection color neutral low-stress resin lens includes the following steps:

[0048] S1: Prepare the hardening layer: immerse the ultrasonically cleaned resin lens substrate in a hardening liquid aqueous solution with a mass percentage of 25-30%, the immersion temperature is 10-20°C, and after immersion for 5-10 seconds, the thickness is 1.0-3.0mm. Pull out the solution at a speed of 1 / s, dry at 70-90°C for 2-4 hours, take out the above-mentioned resin lens substrate and send it to a drying oven for drying and curing. The curing temperature is 110-130°C, and the curing time is 120-240min. A resin lens containing a hardening layer is obtained; preferably, the resin lens substrate is immersed in an aqueous hardening liquid solution with a mass percentage of 27%; the immersion temperature is 15° C., the time is 5 seconds, and the pulling speed is 2.0mm / s, 75°C drying time is 3h; preferably, the cur...

Embodiment 1

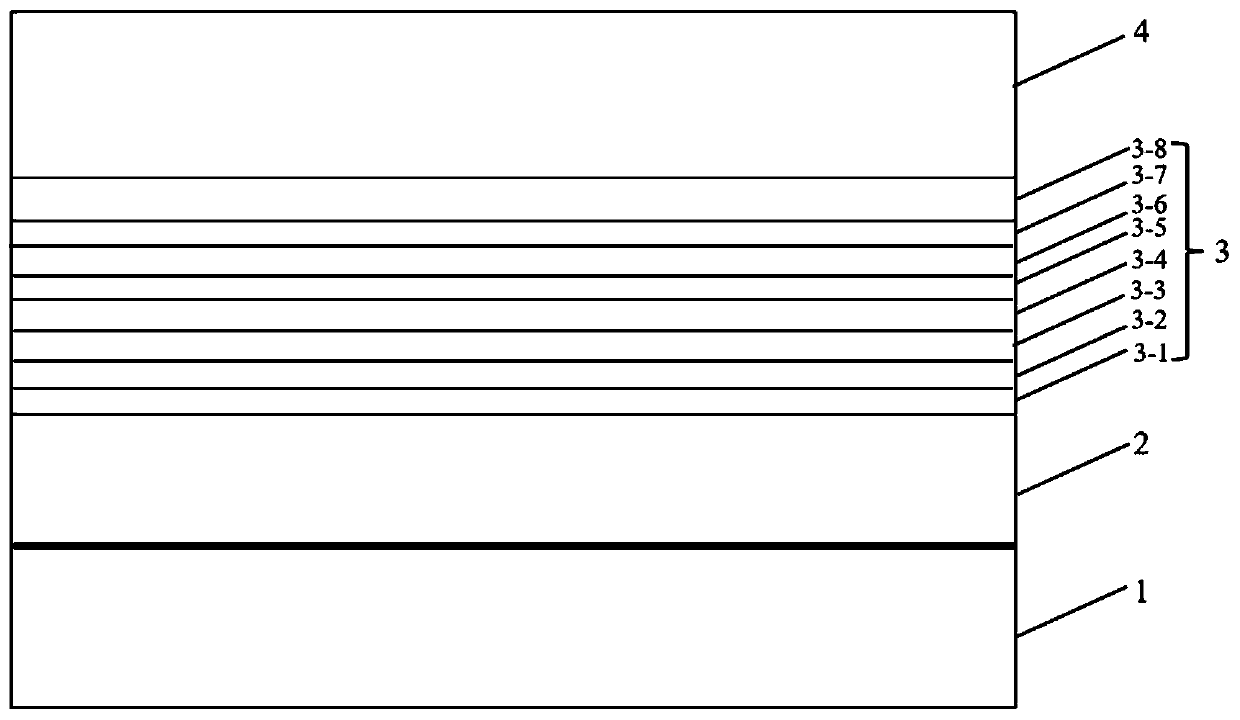

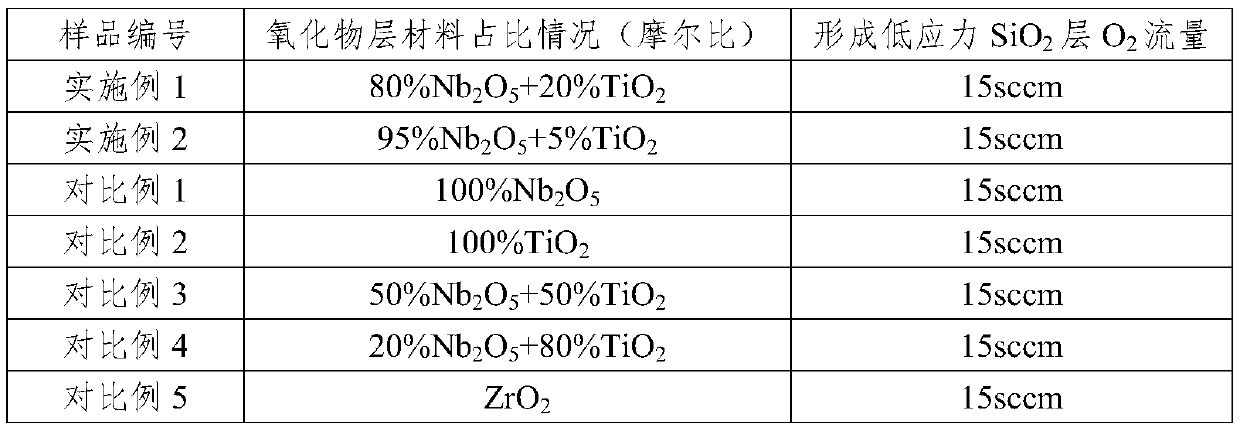

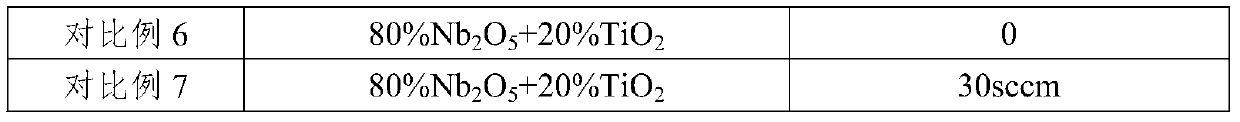

[0063] A low-reflection, color-neutral, and low-stress resin lens, which includes: a resin lens substrate 1 (MR-8); a hardened layer 2 (Z117) / 2.6-3 μm; an anti-reflection layer 3 including: low-stress SiO 2 Layer 3-1 / 13.3nm, niobium-titanium composite oxide layer 3-2 (wherein Nb 2 o 5 and TiO 2 Mole percentage: 80% Nb 2 o 5 , 20%TiO 2 ;Entrusted Changzhou Zhanchi Optoelectronics Technology Co., Ltd. to develop and produce, the material model is PTN57) / 16.7nm, low stress SiO 2 Layer 3-3 / 33.8nm, niobium-titanium composite oxide layer 3-4 (material same as 3-2) / 59.3nm, low stress SiO 2 Layer 3-5 / 11.1nm, niobium-titanium composite oxide layer 3-6 (material same as 3-2) / 37.1nm, ITO layer 3-7 / 5nm; low stress SiO 2 Layer 3-8 / 89.4nm; waterproof layer 4 (using fluorine-containing waterproof materials (such as containing perfluoroalkane (C 12 f 27 N)) / 10nm); The preparation method of the resin lens comprises the following steps:

[0064] S1: Make the hardening layer: immerse th...

Embodiment 2

[0074] A low-reflection, color-neutral, and low-stress resin lens, which includes: a resin lens substrate 1 (MR-8); a hardened layer 2 (Z117) / 2.6-3 μm; an anti-reflection layer 3 including: low-stress SiO 2 Layer 3-1 / 28.2nm, niobium-titanium composite oxide layer 3-2 (wherein Nb 2 o 5 and TiO 2 Mole percent: 95% Nb 2 o 5 , 5%TiO 2 ; Entrust Changzhou Zhanchi Photoelectric Technology Co., Ltd. to develop and produce, the material model is PTN95) / 17.1nm, low stress SiO 2 Layer 3-3 / 38.1nm, niobium-titanium composite oxide layer 3-4 (material same as 3-2) / 55.5nm, low stress SiO 2 Layer 3-5 / 12.6nm, niobium-titanium composite oxide layer 3-6 (material same as 3-2) / 39.8nm, ITO layer 3-7 / 5nm; low stress SiO 2 Layer 3-8 / 90.2nm; waterproof layer 4 (using fluorine-containing waterproof materials (such as containing perfluoroalkane (C 12 f 27 N)) / 10nm); Example 1 of the preparation method of the resin lens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com