Diffraction device and method for nondestructive testing of orientation uniformity of crystals in workpiece

A diffraction device and diffractometer technology, which is applied in material analysis using radiation diffraction, measuring devices, material analysis using wave/particle radiation, etc., can solve problems such as long time-consuming, long detection time, and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

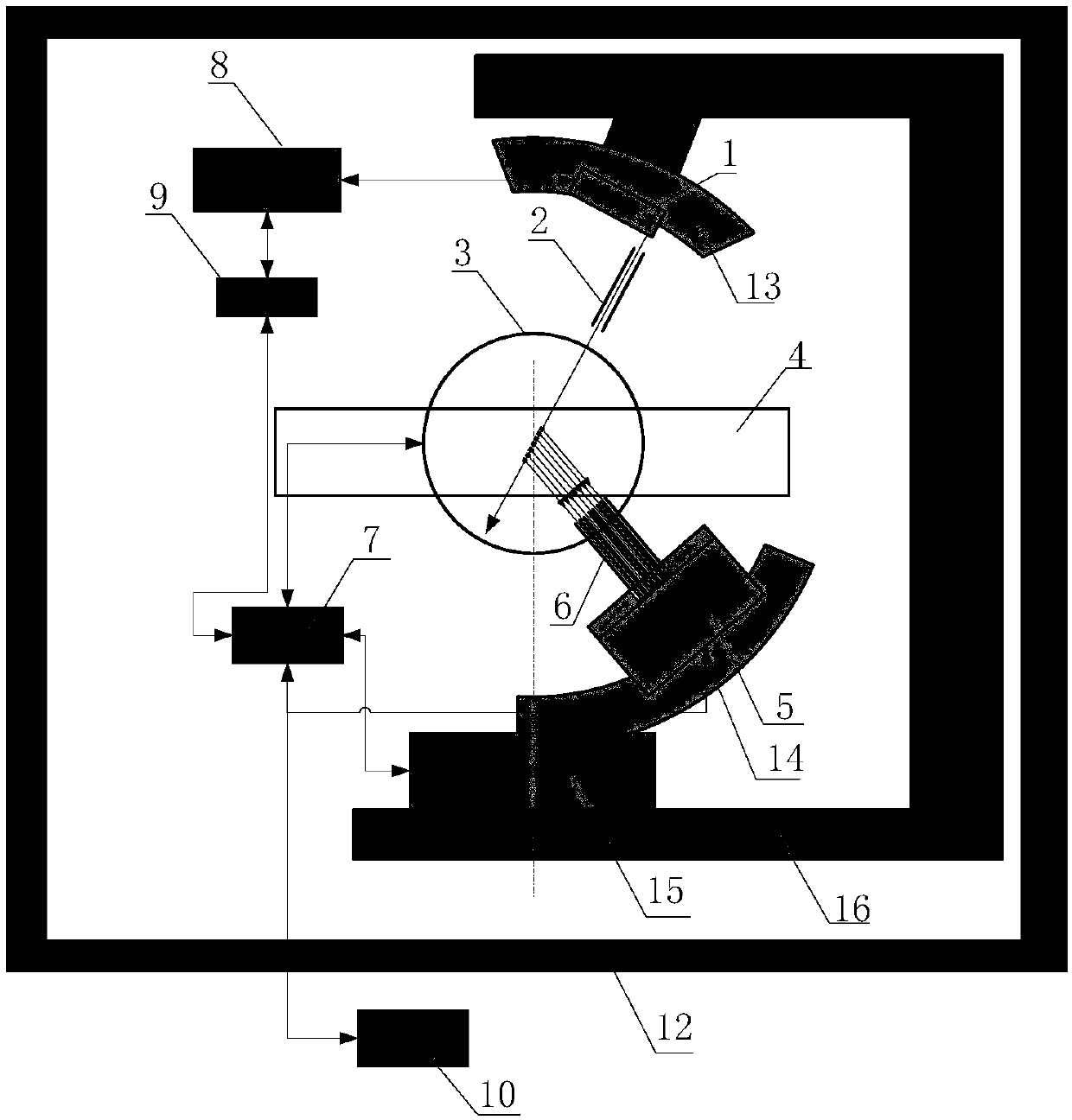

[0050] The focus of this embodiment is to introduce the detection equipment used in the method of the present invention-diffraction device.

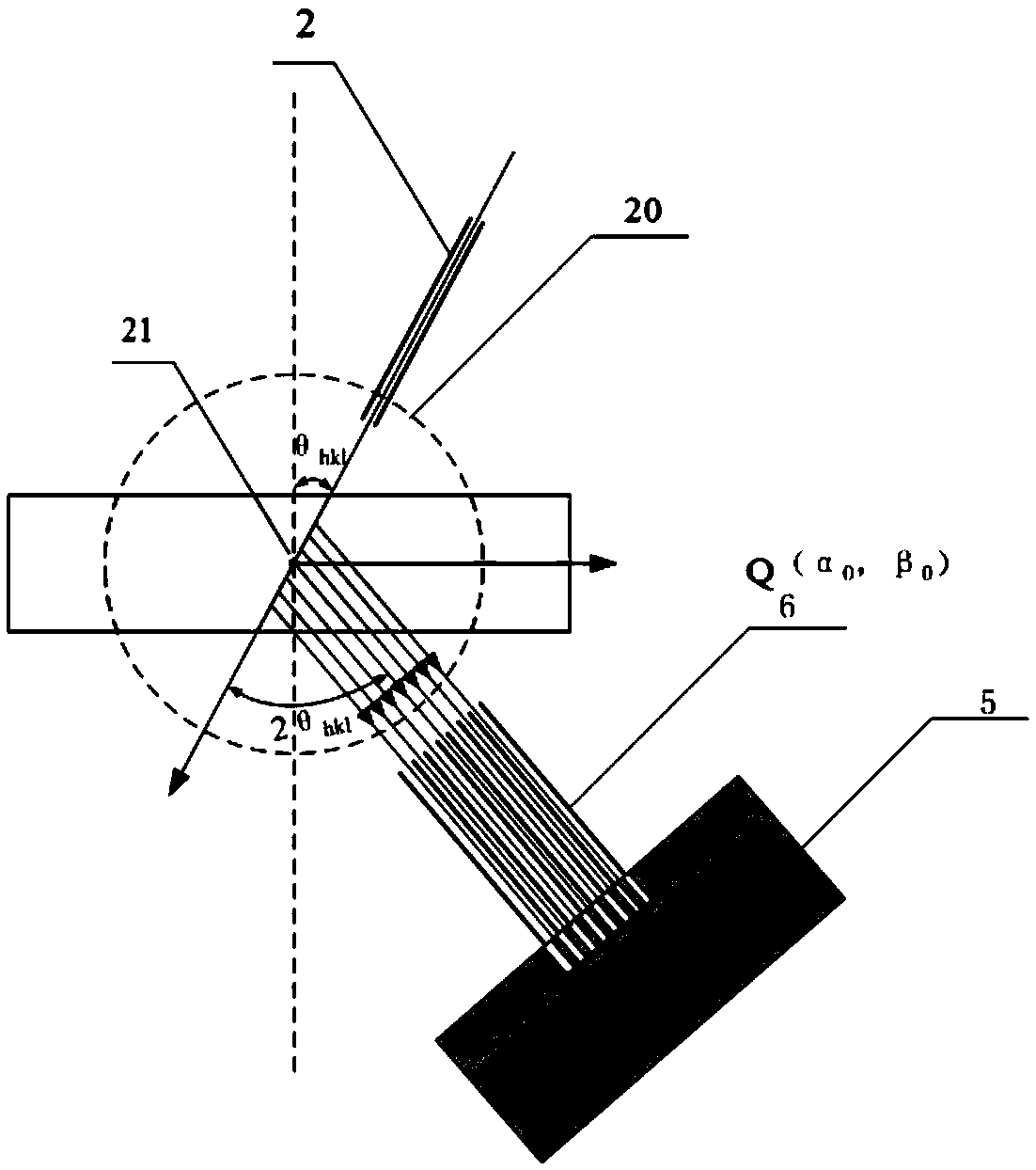

[0051] A diffractive device such as figure 1 , Figure 3 to Figure 6 shown. The device includes: a heavy metal anode target X-ray tube 1, an incident collimator 2, a sample stage 3 for installing a sample 4, each detection unit has an array detector 5 for single photon measurement and a receiving array collimator fixed in front of the array detector 5. Straightener 6, main control computer 7, high voltage generator 8, controller 9, remote operation terminal 10, X-ray shielding shield 12, θ angle rotation mechanism 13 of heavy metal anode target X-ray tube 1, receiving array collimator 6 + The array detection system composed of the array detector 5, the 2θ angle rotation mechanism 14 of the array detection system, the β angle rotation mechanism 15 of the array detection system and the frame 16 of the device.

[0052] Among them, the di...

Embodiment 2

[0065] A method for non-destructive testing of the uniformity of crystal orientation inside a workpiece, using the diffraction device in Example 1 to detect the uniformity of crystal orientation inside a cold-rolled 25mm thick 2024 aluminum plate, see Figure 7 As shown, the specific steps are as follows:

[0066] Step 1: Select the diffracted short-wavelength characteristic X-rays, and set the wavelength λ 0 =0.0211nm, set photon energy as E 0 =59.3kev;

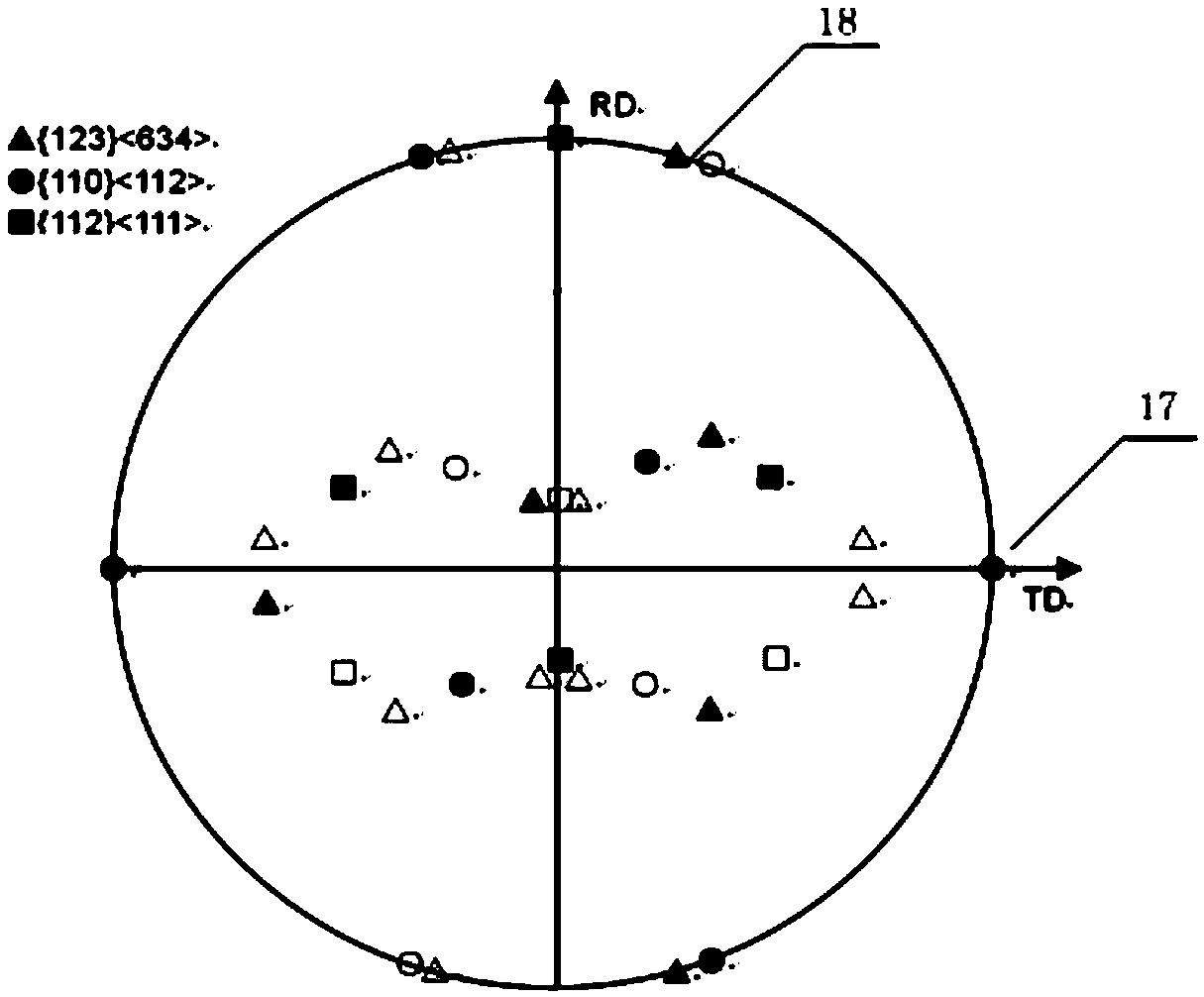

[0067] Step 2: Use XRD detection to analyze the crystal orientation distribution of the 2024 aluminum plate, the measured {111} pole figure of the middle layer and its analysis results, such as figure 2 shown, select figure 2 The direction of the point shown in 17 on the pole figure (the intersection of the outer circle of the pole figure and the transverse TD direction) is taken as the direction of the diffraction vector Q to be measured, and Q(α 0 ,β 0 )=Q(0,0), that is, the direction angle (orientation angle) is α0...

Embodiment 3

[0077] A method for non-destructively testing the uniformity of crystal orientation inside a workpiece, which is used to detect the uniformity of crystal orientation inside a cold-rolled 20mm thick 7075 aluminum plate in linear motion.

[0078] Detection method, step and used diffraction device are the same as embodiment 1 and embodiment 2 in the present embodiment, difference is following parameter selection:

[0079] select figure 2 The direction of the point shown in 18 (the angle with the transverse TD direction is 68° and the intersection point of the outer circle of the polar figure) is taken as the direction of the diffraction vector Q to be measured, that is, the diffraction vector Q(α 0 ,β 0 )=Q(0,68°);

[0080] In this embodiment, the distance from the center of the diffractometer circle of the diffractometer to the window of the W target X-ray tube is 150 mm, the incident collimator is made of tungsten alloy, and its aperture is a rectangular hole. The angle is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Divergence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com