Device for measuring filtering efficiency of filter element

A technology of filtration efficiency and filter element is applied in the field of detection and measurement of purification devices, which can solve the problems of low cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

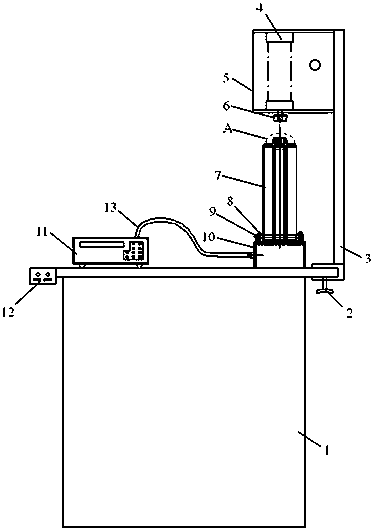

[0031] Such as figure 1 As shown, a device for measuring the filtration efficiency of a filter element includes a base 1, a detection mechanism 11 and a sealing box 10 arranged on the top surface of the base 1, and a power supply for the whole device.

[0032] The detection mechanism 11 and the sealing box 10 are communicated through the intake pipe 13; the special-shaped filter element 7 is arranged on the top of the sealing box 10, the compression cylinder 4 is arranged above the special-shaped filter element 7 through the support mechanism, and the compression cylinder 4 and the special-shaped filter element 7 are coaxially arranged .

[0033] The free end of the cylinder rod of the compression cylinder 4 is provided with a positioning pressing member 6 .

[0034] At least one ventilation hole is arranged on the top of the sealed box 10 .

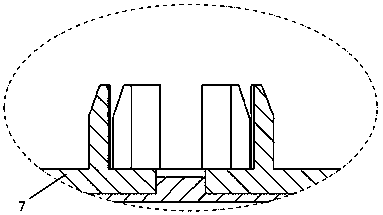

[0035] The flange at the bottom end of the special-shaped filter element 7 is fixedly connected with the top of the sealing box 10 th...

Embodiment 2

[0044] Based on Embodiment 1, in order to further facilitate the control of the detection mechanism and the corresponding feedback display of the detection results, the device for measuring the filtration efficiency of the filter element further includes a controller 12 electrically connected to the detection mechanism 11 . The controller 12 is any one or a combination of control buttons or display screen controllers.

[0045] The usage method of the present invention:

[0046] The filter element to be inspected and the sealing box are fixedly connected by nuts and locking washers to form a closed body, which ensures complete compression, compactness, and airtightness before the inspection begins. Start the detection mechanism, the detection mechanism has a built-in air extraction device to pump air, and the air enters the detection mechanism after being filtered by the filter element. The detection mechanism can detect the current air quality of the gas in the sealed box, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com