Heating furnace assembly of high-temperature friction-wear experimental instrument and using method of heating furnace assembly

A technology of friction and wear and heating furnace, which is applied in the direction of instruments, scientific instruments, and testing wear resistance, etc. It can solve the problems of not being too long for a single test, reducing the service life of equipment, and affecting heating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

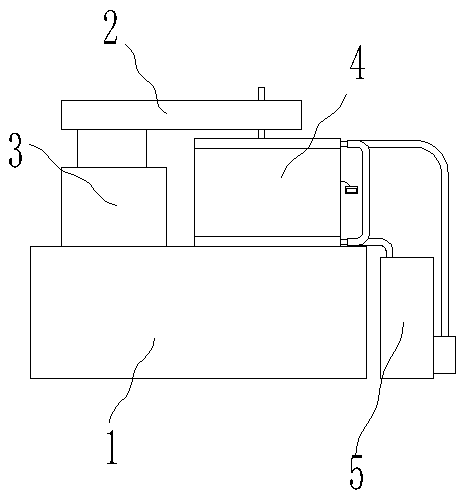

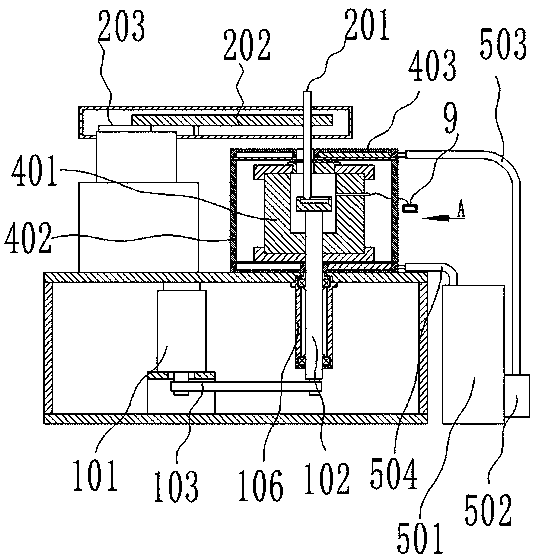

[0040] Embodiment one, such as Figure 1-3As shown, a heating furnace assembly of a high-temperature friction and wear tester includes a machine base 1, a dynamometer head 2, a machine head support 3 and a heating furnace assembly 4, and the machine head support 3 and the heating furnace assembly 4 are fixedly connected to the machine base 1 Above, the dynamometer head 2 is connected to the head support 3, the dynamometer head 2 is arranged above the head support 3 and the heating furnace assembly 4, and the dynamometer head 2 includes a loading bar 201, a beam 202 and a force Value sensor 203, the loading rod 201 is connected on the beam 202, the force sensor 203 is connected between the beam 202 and the head support 3, the loading rod 201 is inserted into the heating furnace assembly 4, and the motor 101 is arranged in the base 1 , a rotating shaft 102, a gear toothed belt 103, a friction disc 104 and a detection piece 105, the rotating shaft 102 is rotatably connected in th...

Embodiment 2

[0046] Embodiment two, such as Figure 4 As shown, a bearing housing 106 is further provided in the machine base 1, the bearing housing 106 is fixedly connected to the upper part of the machine base 1, and the rotating shaft 102 is rotatably connected in the bearing housing 106 through a bearing, and the return pipe 504 runs through the machine base 1. The return water pipe 504 is spirally wound outside the bearing housing 106 in the machine base 1, and the rotating shaft 102 is fixed and supported through the bearing housing 106, and the heat is transferred to the bearing housing 106 through the bearing, and then the heat is dissipated through the return water pipe 504.

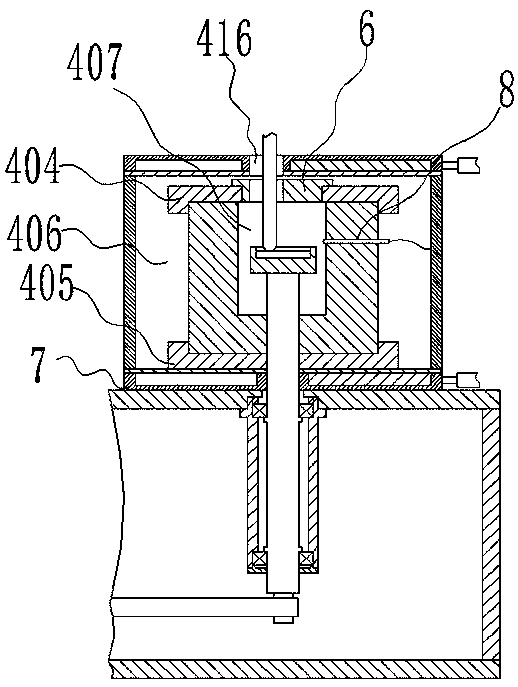

[0047] Further, the thermal insulation cavity 406 is filled with thermal insulation materials, which can effectively insulate heat, reduce heat transfer to the outside on the one hand, and ensure the temperature maintenance effect of the heating cavity 407 on the other hand. The thermal insulation materials c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com