Multi-stage heat exchange structure for deaerator

A technology of heat exchange structure and deaerator, which is applied in the direction of preheating, feed water heater, lighting and heating equipment, etc., and can solve the problem of low deaeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

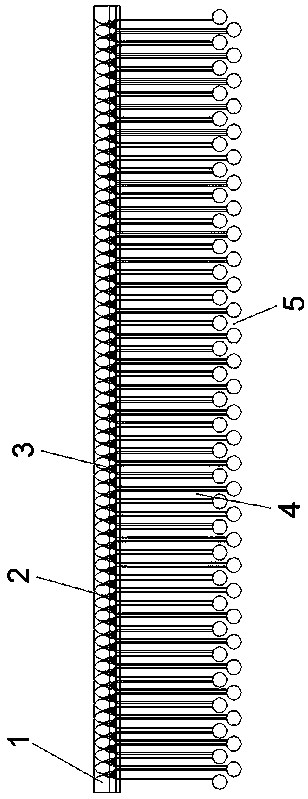

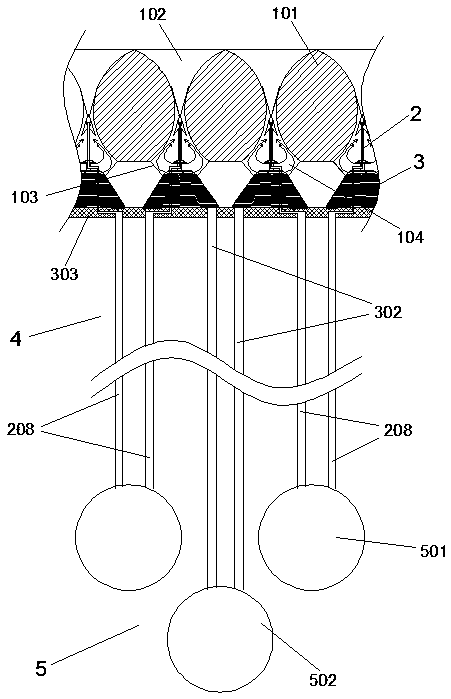

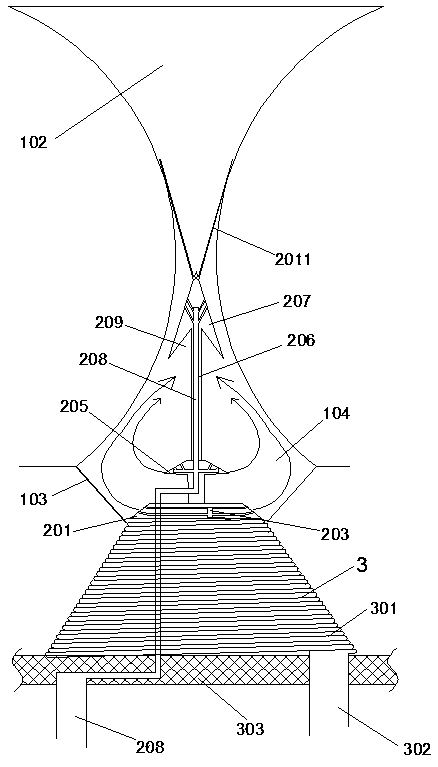

[0034] Such as Figure 1-5 As shown, a multi-stage heat exchange structure for a deaerator includes a water divider 1, and the water divider 1 includes a horizontally arranged water divider 101, and on the water divider 101 are distributed a number of water dividers that run through its thickness direction for The water distribution hole 102 for water guide, the section of each water distribution hole 102 is a hyperbolic shape, and the bottom of each water distribution hole 102 is provided with a rounded table-shaped gas collection cover 103 surrounding the water distribution hole 102, and the collection The air cover 103 cooperates with the lower part of the water distribution hole 102 to form the gas gathering cavity 104, and the gas jet assembly 2 is arranged in the gas gathering cavity 104, and the gas jet component 2 includes the first jet disc 201 and is arranged on the first jet via the connecting rod 206. The second air injection disk 207 on the disk 201, wherein the f...

Embodiment 2

[0041] This embodiment is an improvement made on the basis of Embodiment 1, and its basic structure is the same as that of Embodiment 1, the difference is that: figure 1 and 2 As shown, the fourth heat exchange area 5 is arranged below the water separator 1, and the fourth heat exchange area 5 includes a plurality of first steam branch pipes 502 arranged parallel to the water separator 101 and a layer parallel to the water separator 101. A plurality of second steam branch pipes 501 provided on the water dividing plate 101, and each first steam branch pipe 502 is correspondingly arranged below the middle position of the two second steam branch pipes 501, and the diameter of the first steam branch pipe 502 is greater than two The gap between the second steam branch pipes 501 forms a "herringbone" channel for water flow to pass through;

[0042] The water distribution holes 102 on the water distribution plate 101 are evenly distributed in rows, and each row of water distribution...

Embodiment 3

[0045] This embodiment is another improvement made on the basis of embodiment 1, and its basic structure is the same as that of embodiment 1, the difference is that: Figure 6 As shown, the water distributing hole 102 includes an upper outer expansion water area 1021, a middle narrow area 1022 and a bottom outer diffusion water area 1023, so that the deoxygenated water is steamed from bottom to top when passing through the narrow area 1022 Purge and disperse downward against the side wall of the outer diffusion water area 1023, improving the heating efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com