Acorn-shaped ring groove single-face fastening part and mounting method thereof

A fastener and ring groove technology, applied in the direction of threaded fasteners, connecting components, screws, etc., can solve problems such as damage to the clamped parts and loosening of riveted joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0031] In conjunction with the accompanying drawings.

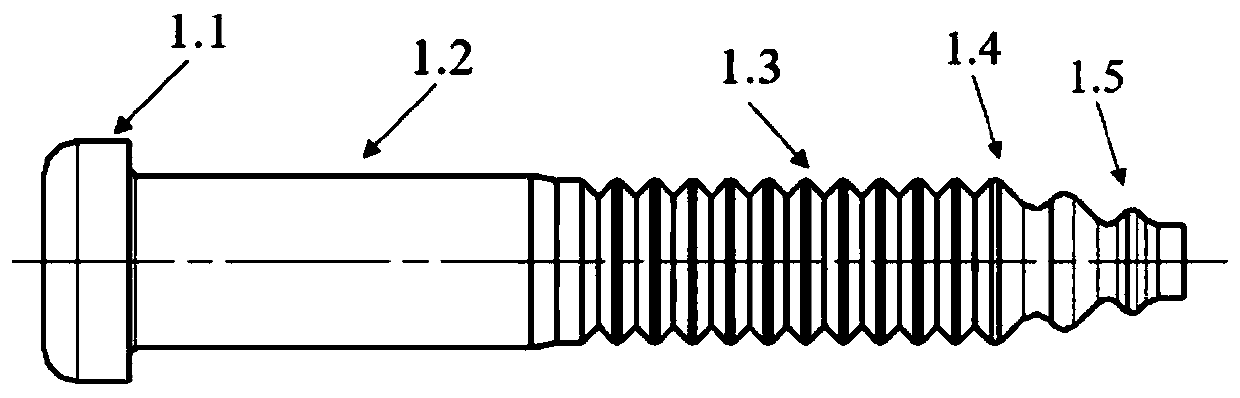

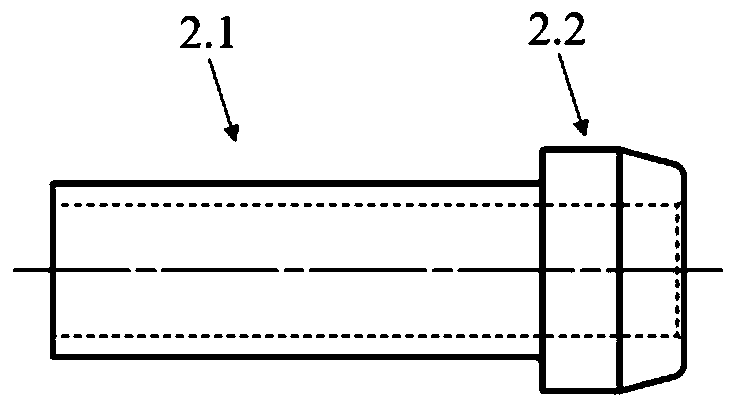

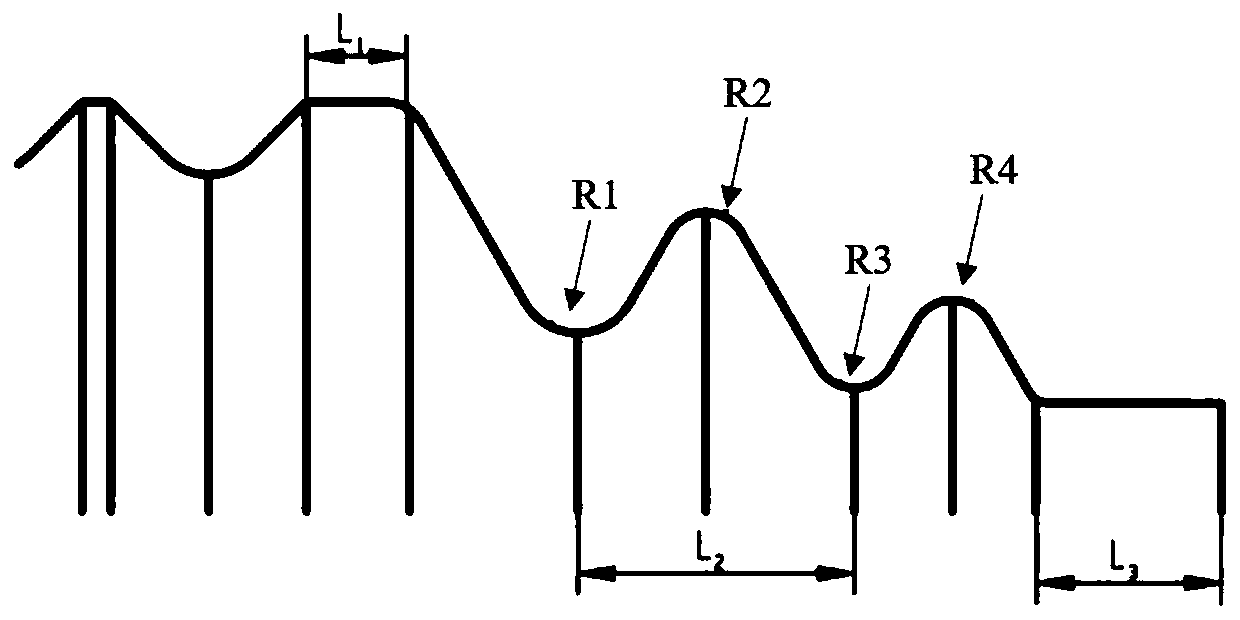

[0032] Acorn-shaped ring groove single-sided fasteners, including rivets and collars, the rivets are composed of rivet head 1.1, polished rod 1.2, locking groove 1.3, ring groove transition section 1.4 and tail pull groove 1.5, and the collar is composed of sleeve 2.1 and riser 2.2; the tail structure of the rivet has a plurality of tail grooves 1.5 whose diameters successively decrease along the rivet axis.

[0033] Parallel tail grooves with successively decreasing diameters 1.5 The maximum diameter difference H between the upper stage and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com