Textile printing and dyeing cooling device with wastewater collection function

A technology for textile printing, dyeing, and cooling devices, which is applied in the directions of processing textile material equipment configuration, textile and papermaking, heating/cooling fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

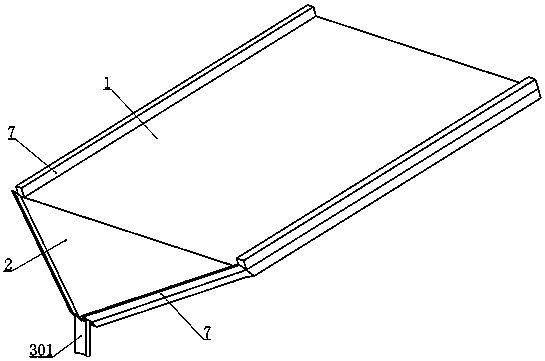

[0028] Example: as attached figure 1 , 2 , 3, 4, 5, 6, 7, 8 and attached Figure 9 As shown, a textile printing and dyeing cooling device with waste water collection function includes a cooling box 11, an inlet and outlet 12 arranged on the cooling box 11, a blower 13 arranged on the cooling box 11, and The air outlet pipe 14 arranged in the cooling box 11 and arranged along the cloth advancing direction also includes a rectangular water receiving plate 1 arranged under the cloth and inclined to the side of the cloth advancing direction, and is arranged on the rectangular water receiving plate 1, the triangular deflector 2 on the lower side, the combined threaded pipe unit 3 arranged on the horizontal bottom surface of the triangular deflector 2, the water bottle 4 arranged on the combined threaded pipe unit 3, arranged on the The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center angle | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com